Steel plate coating processing equipment and processing method thereof

A technology for processing equipment and steel plates, which is applied in the field of steel plate coating processing equipment, and can solve problems that affect the safety of the device, cumbersome operation process, coating damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

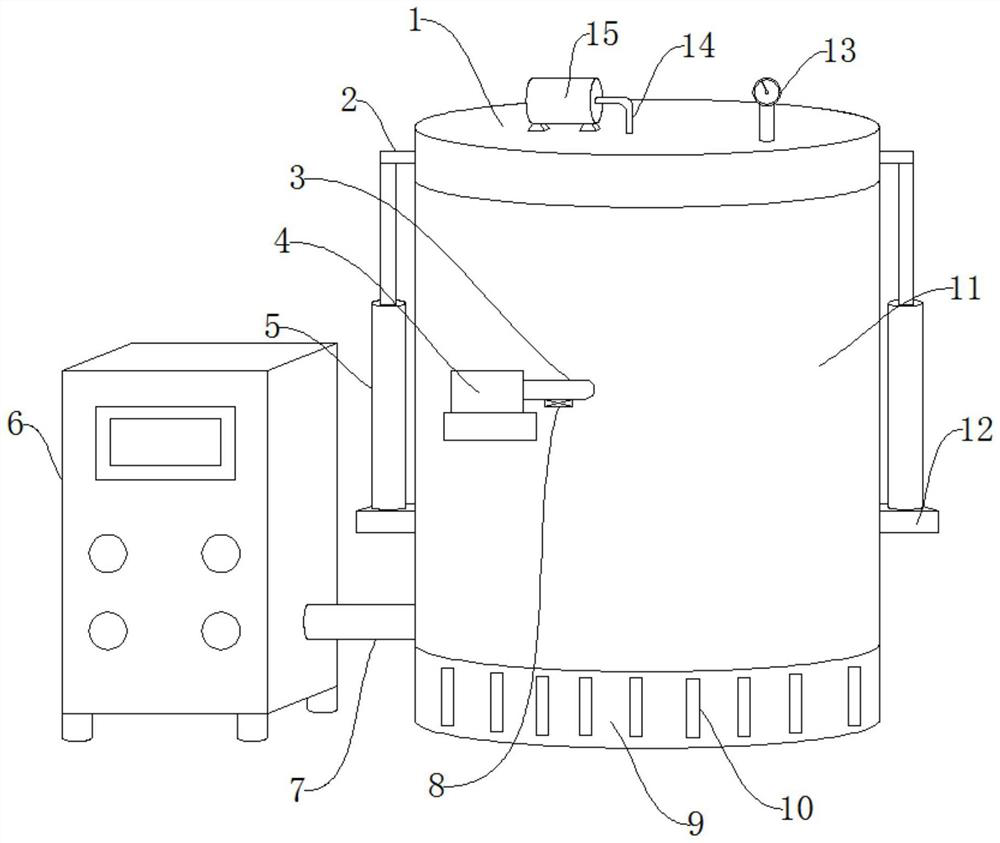

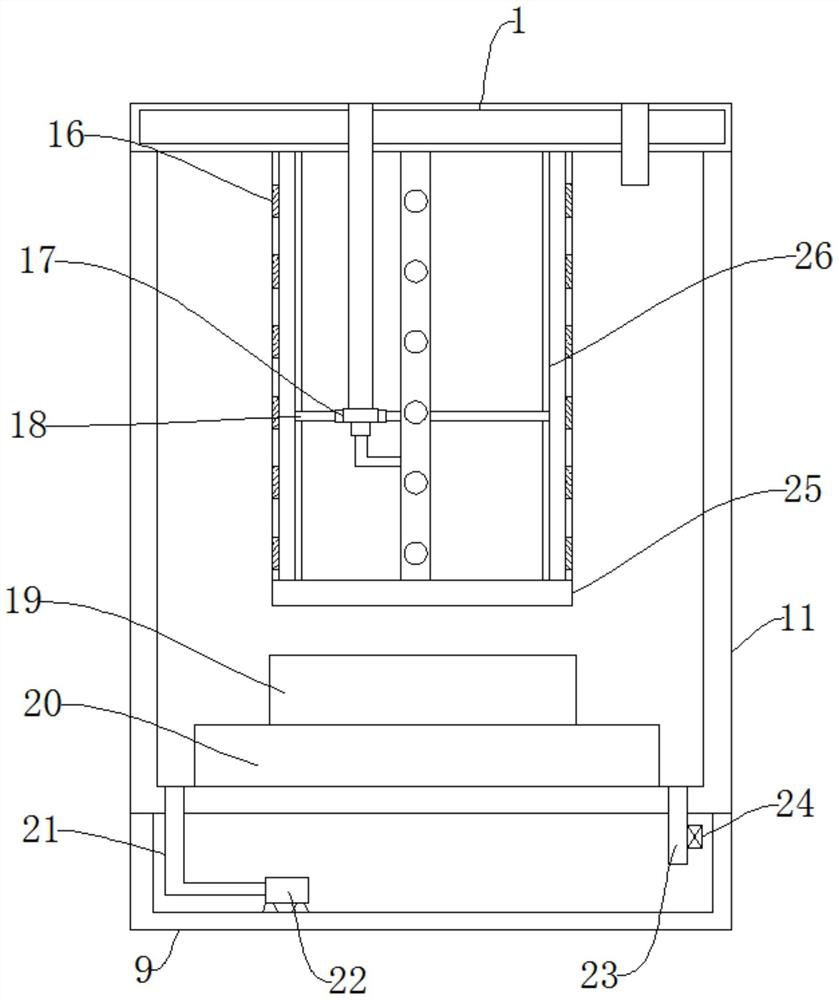

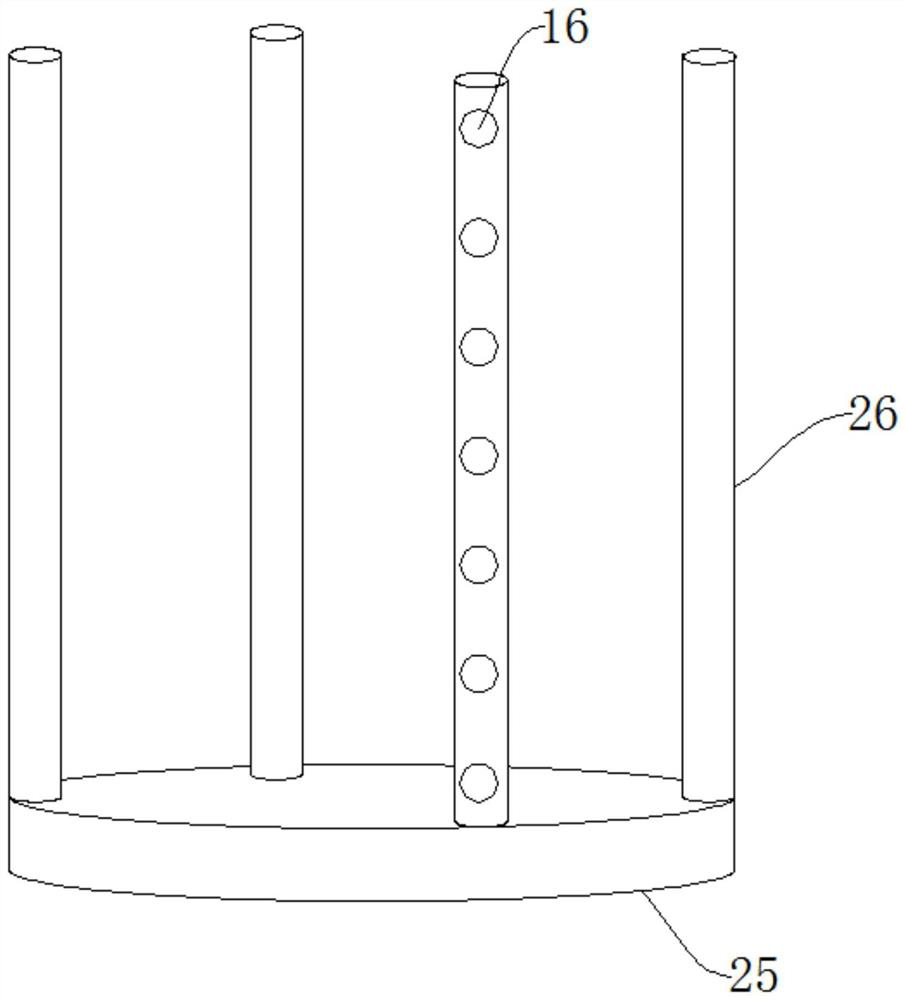

[0034] Such as Figure 1-Figure 4As shown, the coating processing equipment for steel plates includes a base 9, a vacuum tank 11, a tank cover 1 and a hydraulic rod 5, the upper end of the base 9 is provided with the vacuum tank 11, and the upper end of the vacuum tank 11 is provided with the tank cover 1. A bearing plate 12 is fixed on both side walls of the vacuum tank 11, the hydraulic rod 5 is installed on the upper end of the bearing plate 12, the connecting rod 2 is fixed on the top end of the hydraulic rod 5, and the inner wall of the tank cover 1 A fixed rod 26 is arranged on the top, the bottom end of the fixed rod 26 is provided with a bottom plate 25, a vacuum pump-15 is installed on the upper end of the tank cover 1, a vacuum tube-14 is connected to the vacuum pump-15, and one end of the vacuum tube-14 is connected to There is a four-way valve 17, the four-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com