Ultrasonic probe clamping rod, ultrasonic detection device and use method of ultrasonic detection device

An ultrasonic probe and clamping rod technology, which is applied to measuring devices, mechanical measuring devices, and uses ultrasonic/sonic/infrasonic waves, etc., can solve the problems of cumbersome on-machine thickness measurement and the inability of clamping rods to be used universally. range, improve the accuracy of ultrasonic measurement, and expand the effect of the measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

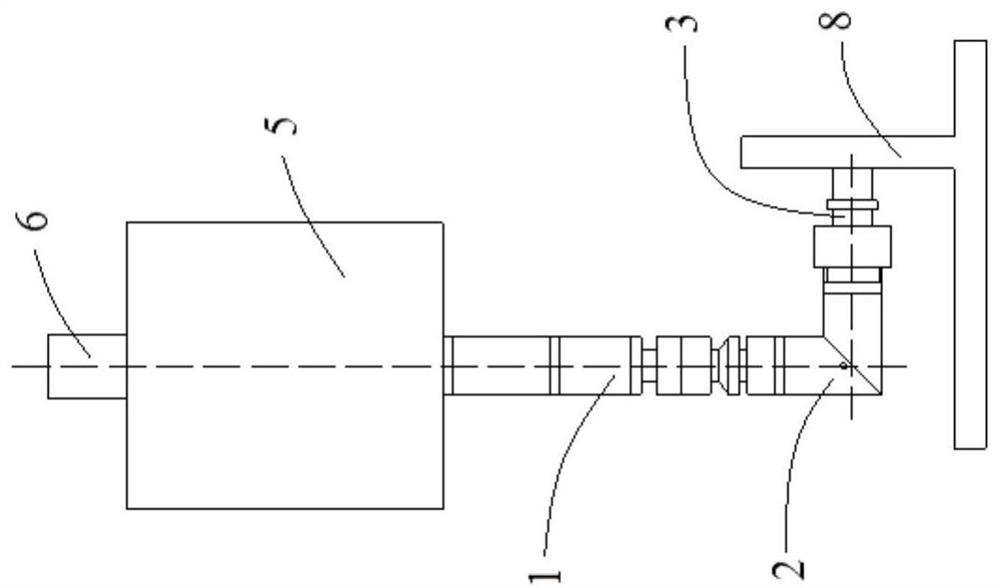

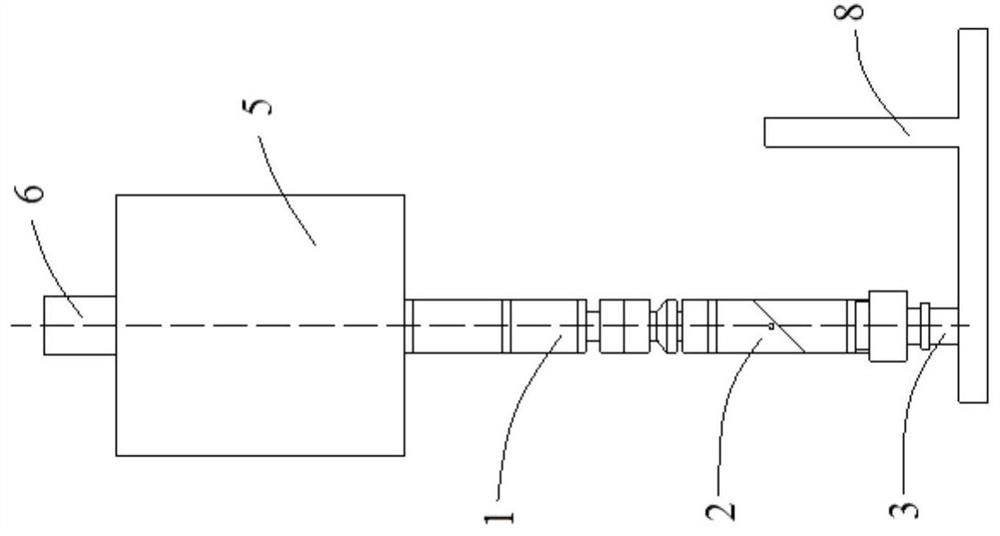

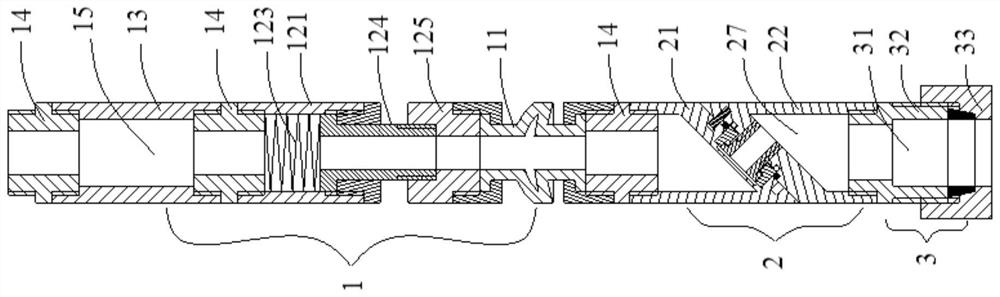

[0064] An ultrasonic probe clamping rod. The ultrasonic probe clamping rod is spliced by a plurality of functional modules in different orders according to the needs of use. The functional modules include a rotatable indexing module 2 and a clamping module for clamping the ultrasonic probe 4. 3. The telescopic module 12 whose length can be changed, the angle deflection module 11 that can be deflected, the connection module 14 for connection, and the extension module 13 for increasing the length of the ultrasonic probe clamping rod, etc. Such as figure 1 and figure 2 As shown, it includes an indexing module 2, a clamping module 3 and a straight rod part 1 spliced by other above-mentioned modules. Such as image 3 As shown, the straight rod part 1 is provided with a first through hole 15 along its axis direction, the indexing module 2 is provided with a second through hole 27 along its axis direction, and the clamping module 3 is provided with a third through hole 27 alon...

Embodiment 2

[0074] An ultrasonic probe clamping rod, the difference from the technical solution in Embodiment 1 is that the straight rod part 1 in this embodiment includes an angle deflection module 11, and the angle deflection module 11 is provided with a fourth through hole along its own axis 113 . In this embodiment, the fourth through hole 113 is a component of the first through hole 15 .

[0075] Such as Figure 12 As shown, the two ends of the angle deflection module 11 are connection parts 111, the connection part 111 is a tubular structure, a fifth flange 1111 is provided on the inner side of one end of the connection part 111, and the surface of the connection part 111 is provided with threads for connecting with other structures. A deformation piece is provided between the two connecting parts 111, and a sixth flange 1123 and a seventh flange 1124 are provided on the deformation piece. After the angle deflection module 11 is connected with other structures, the sixth flange 1123...

Embodiment 3

[0079] An ultrasonic probe clamping rod. The difference from the solutions disclosed in Embodiment 1 and Embodiment 2 is that the straight rod part 1 in this embodiment also includes a telescopic module 12 that can expand and contract. The telescopic module 12 is provided with The fifth through hole 126 in the axial direction, in this embodiment, the fifth through hole 126 is a component of the first through hole 15 . Such as Figure 13 As shown, the telescopic module 12 includes a telescopic cavity 121 and a telescopic column 124, the upper end of the telescopic cavity 121 and the lower end of the telescopic column 124 are provided with a structure for connecting with other structures of the straight rod part 1, such as the connection structure at the lower end of the telescopic column 124 1242 is thread.

[0080]The inner lower end of the telescopic chamber 121 is provided with a third flange 122, the upper end of the telescopic column 124 is provided with a hanging platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com