Automatic slurry performance detection device

An automatic detection device, mud technology, applied in the direction of measuring device, phase influence characteristic measurement, DC flow characteristic measurement, etc., can solve the problems of corrosion filter screen, poor experimental conditions, large deviation of experimental results, etc., to improve accuracy, The effect of reducing errors and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

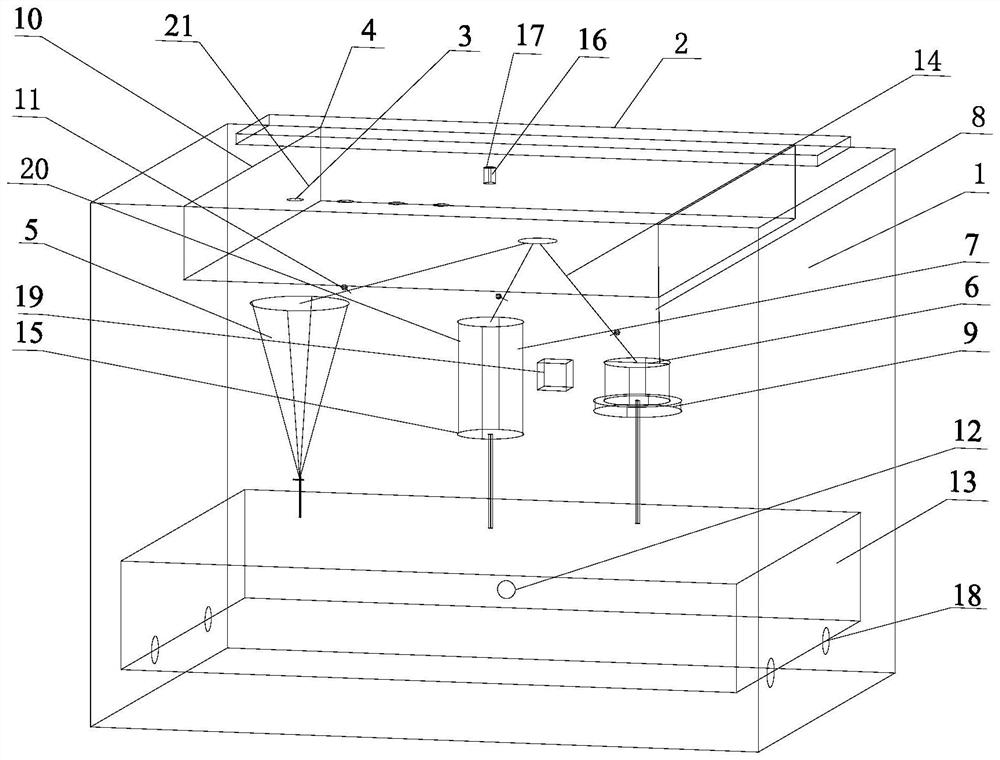

[0016] refer to figure 1 , an automatic detection device for mud performance, including a box body 1, a display screen 2, a control button 3 and an automatic control system 4.

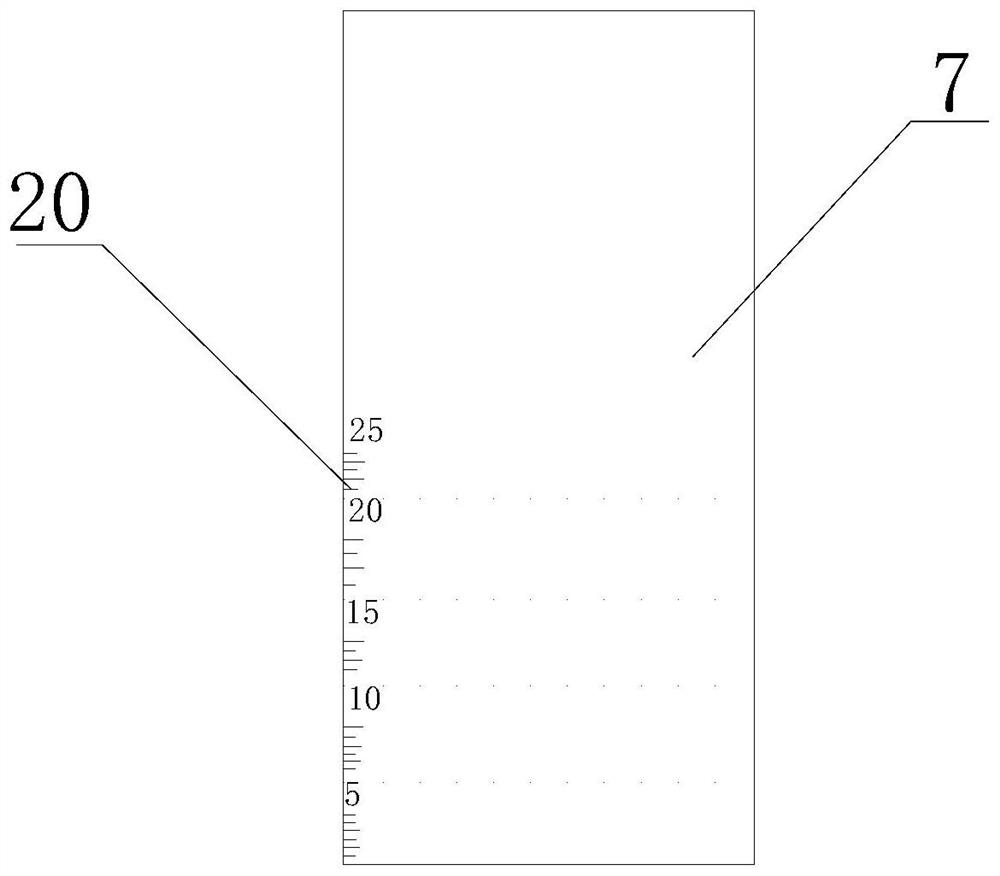

[0017] A slurry storage box 10 is installed in the middle of the casing 1 top, a conical funnel 5 is installed on the left side of the casing 1, a mud sand content measuring cup 7 is installed in the middle, a mud specific gravity scale 9 is installed on the right side, and a refractometer 19 is provided at the mud sand content measuring cup 7 rear.

[0018] Preferably, a feeding port 16 is arranged in the middle of the pulp storage box 10, a removable filter screen 17 is installed above the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com