Device and method for testing thermal performance of medium-magnitude chemical heat storage material

A technology of heat storage material and testing device, which is applied in the direction of measurement device, material thermal development, analysis material, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Take 50g of magnesium oxide, the material to be tested, to test the thermal performance of the heat storage material.

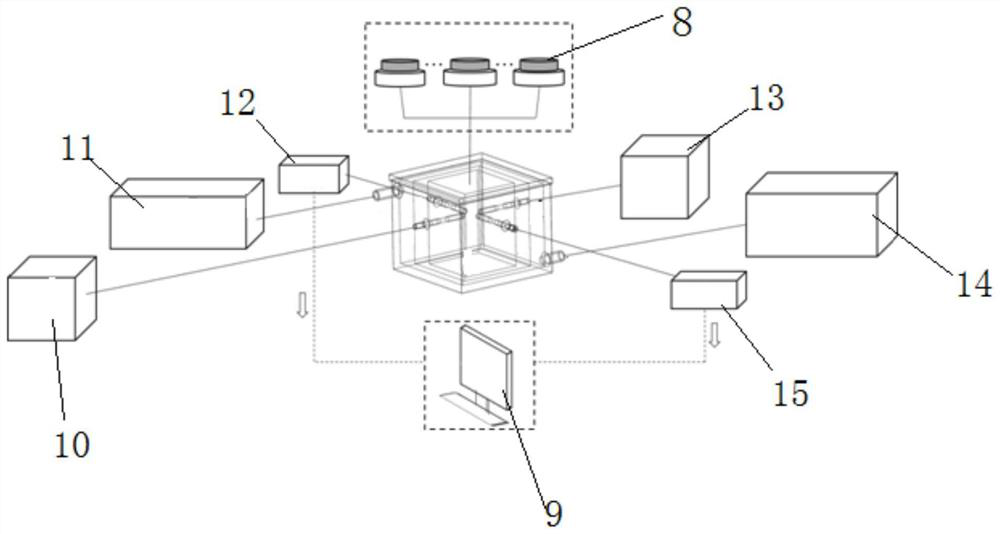

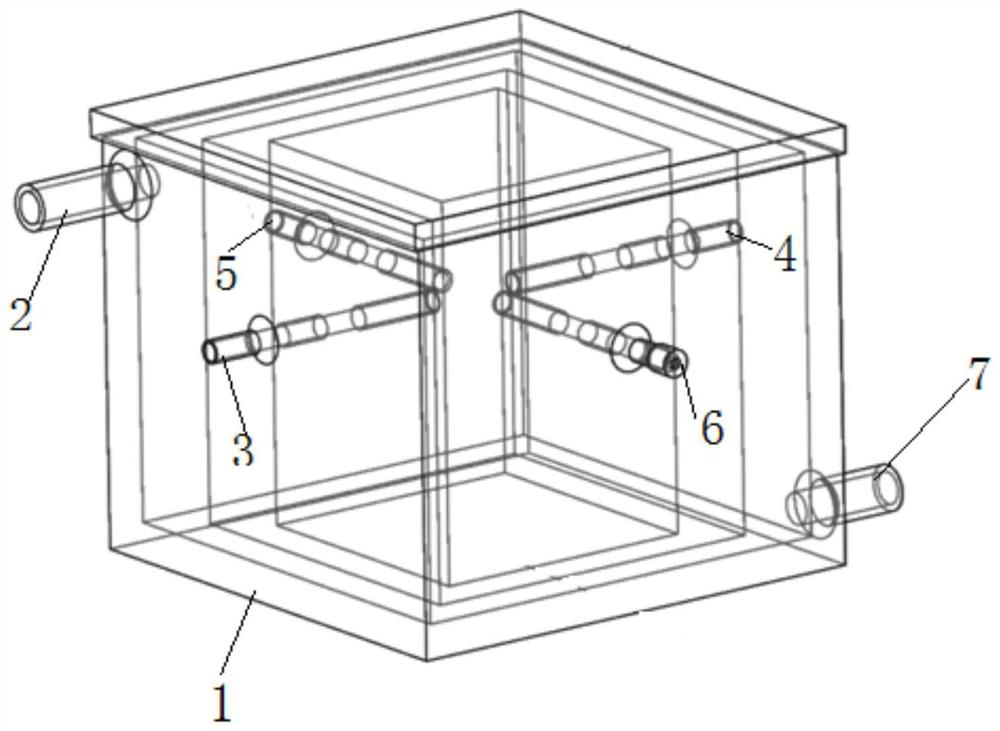

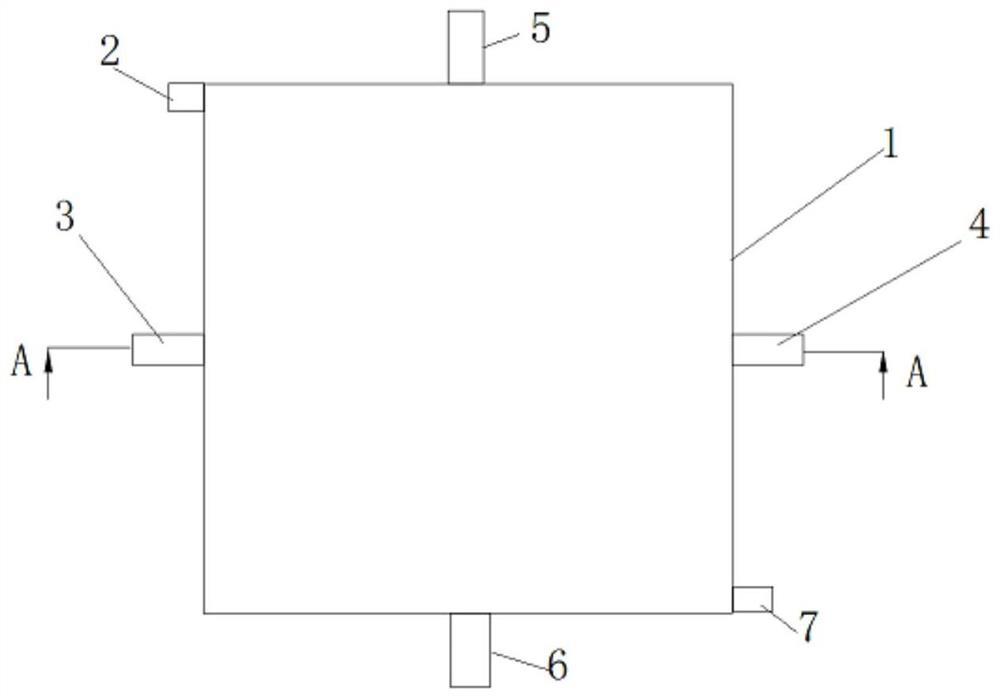

[0056] The performance test of the above materials adopts a medium-scale chemical heat storage material thermal performance testing device, which includes a medium-scale reaction chamber 1, a steam input pipe 3, a steam output pipe 4, a humidity test chamber 5, and a temperature test chamber 6 ; The medium-volume reaction chamber 1 includes an outer cavity, an inner cavity is arranged in the outer cavity, a cavity is formed between the outer cavity and the inner cavity, and a heat exchange fluid is arranged in the cavity; One end of the humidity test chamber 5 extends into the medium volume reaction chamber 1, and a humidity sensing probe is arranged in the humidity test chamber 5; one end of the temperature test chamber 6 extends into the medium volume reaction chamber 1, and the temperature test chamber 6 is provided with a A temperature sensing prob...

Embodiment 2

[0063] This embodiment adopts the same testing device as that of Embodiment 1.

[0064] The test material is magnesium oxide, and the mass of the test material is 30g.

[0065] Open the data receiver. The initial condition of the magnesium oxide reaction is 100°C, the temperature of the heat source is set at 100°C, the steam temperature is set at 100°C, and the flow rate is 5ml / min. Open the valve, and the thermal fluid of the high-temperature heat source is passed into the reaction chamber through the heat exchange fluid inlet, and then flows out through the heat exchange fluid outlet, and is collected in the heat exchange fluid collector. Keep at 100°C, ready for the introduction of water vapor.

[0066] After the temperature of the medium-scale reaction chamber is constant, turn on the steam source and gradually adjust the steam temperature to 150°C. After stabilization, open the valve and pass it into the reaction chamber through the steam input pipe. The reaction chambe...

Embodiment 3

[0069] This embodiment adopts the same testing device as that of Embodiment 1.

[0070] The test material is magnesium oxide, and the mass of the test material is 150g.

[0071] Open the data receiver. The initial condition of the magnesium oxide reaction is 200°C, the temperature of the heat source is set at 200°C, the steam temperature is set at 200°C, and the flow rate is 5ml / min. Open the valve, and the thermal fluid of the high-temperature heat source is passed into the reaction chamber through the heat exchange fluid inlet, and then flows out through the heat exchange fluid outlet, and is collected in the heat exchange fluid collector. Keep it at around 200°C, ready for the introduction of water vapor.

[0072] After the temperature of the medium-volume reaction chamber is constant, turn on the steam source and gradually adjust the steam temperature to 200°C. After stabilization, open the valve and pass it into the reaction chamber through the steam input pipe. The rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com