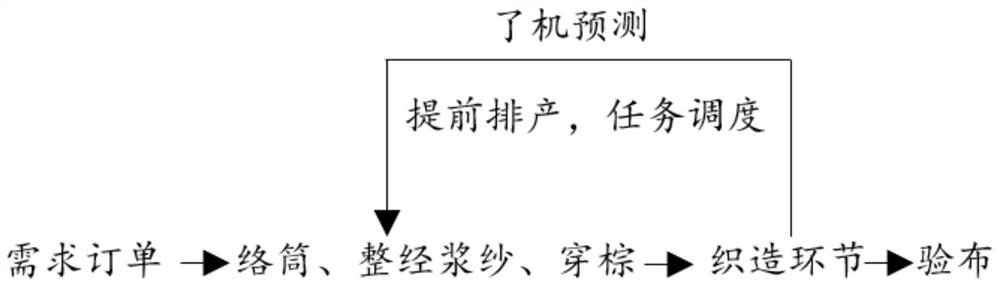

A method and system for predicting loom completion based on loom capacity

A production capacity forecasting and production capacity coefficient technology, which is applied in the field of textile weaving, can solve the problems of enterprise economic losses, reduce production efficiency, and high labor costs, and achieve the effects of improving enterprise benefits, ensuring product delivery, and saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

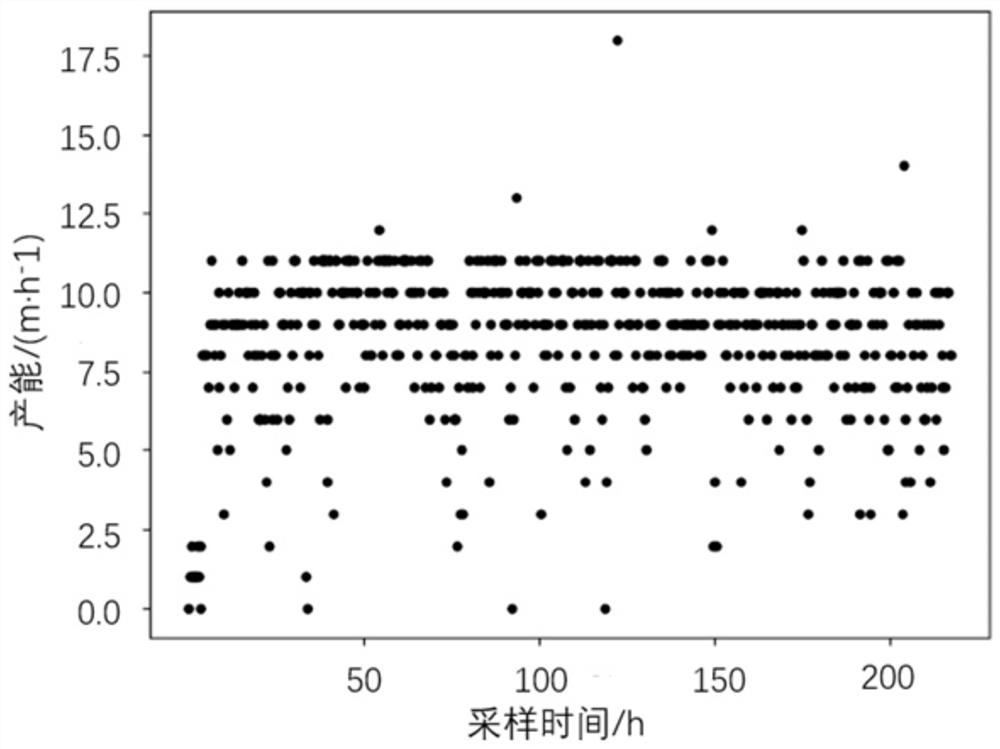

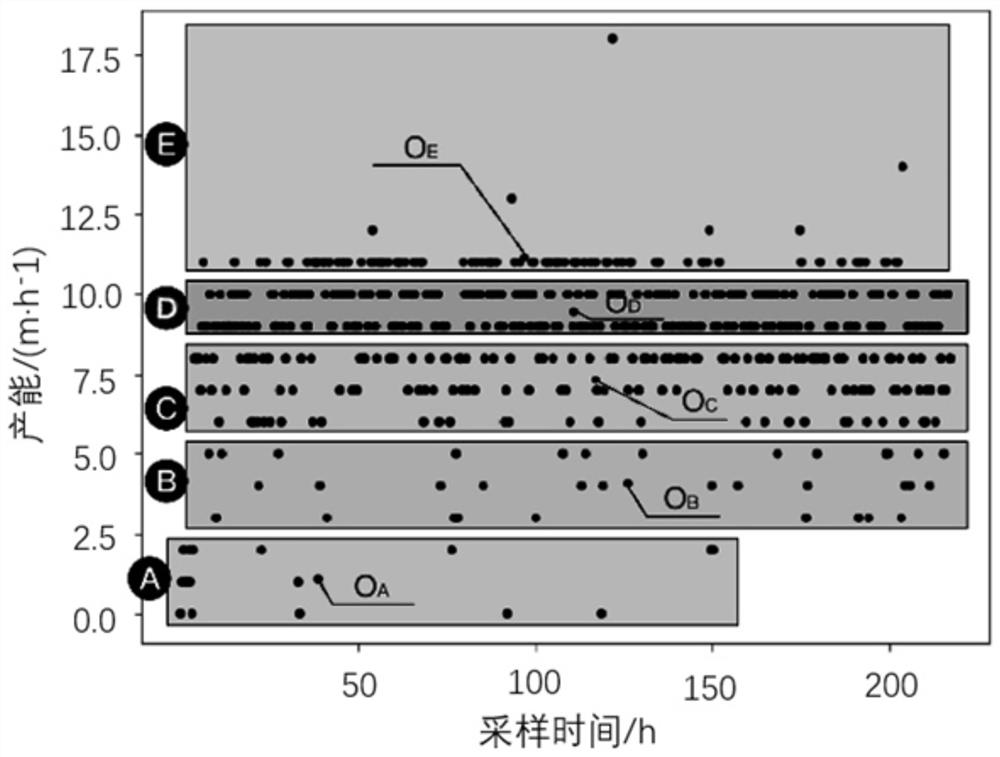

[0096] The embodiment collects the production data of 10 devices, as shown in Table 1.

[0097] Table 1

[0098] sequence Device No Beam number Starting time End Time Total time / h 1 178 H213-012 2021 / 04 / 28 07:49:08 2021 / 05 / 14 20:56:34 397.12 2 041 H179-012 2021 / 04 / 26 12:19:40 2021 / 05 / 09 23:22:06 323.04 3 081 H850-012 2021 / 04 / 29 10:27:47 2021 / 05 / 15 05:09:50 378.7 4 164 4-19+148 2021 / 04 / 24 02:49:51 2021 / 05 / 05 02:56:14 264.11 5 739 H921-01+37 2021 / 04 / 30 07:47:26 2021 / 05 / 15 12:50:16 365.05 6 293 H154-148 2021 / 04 / 28 12:24:21 2021 / 05 / 13 00:08:05 347.73 7 254 H2012-148 2021 / 04 / 23 03:37:20 2021 / 05 / 05 15:12:55 299.59 8 669 X293-01 2021 / 04 / 22 15:41:43 2021 / 05 / 10 21:33:08 437.86 9 610 X117-012 2021 / 04 / 21 00:53:51 2021 / 05 / 02 20:05:13 283.19 10 316 H506-148 2021 / 04 / 25 00:05:52 2021 / 05 / 11 00:57:03 384.85

[0099] The original data is divided into valid production data sample sets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com