Depth granulation calculation method for stockyard

A calculation method and granulation technology, applied in the field of 3D visual recognition, can solve the problems of inaccurate cost, inaccurate coal quality, price, inability to obtain weight ratio data, etc., and achieve the effect of accurate material retrieving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. It should be understood that the content described here is only for illustration and explanation of the present invention, and is not intended to limit the present invention.

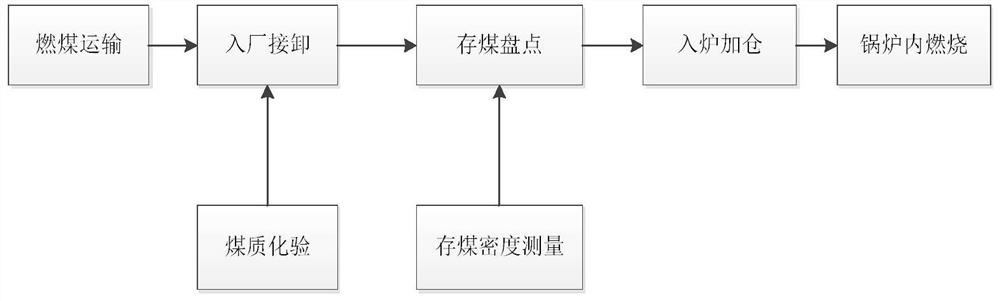

[0020] Such as figure 1 As shown, the basic process of coal combustion management in thermal power plants. The digital coal yard mainly manages coal intake, coal consumption, and coal storage. The coal intake process in thermal power plants is generally unloading operations in the factory, and the coal consumption process is generally furnace loading and storage operations. The coal storage results can be obtained based on the relationship between intake and consumption. .

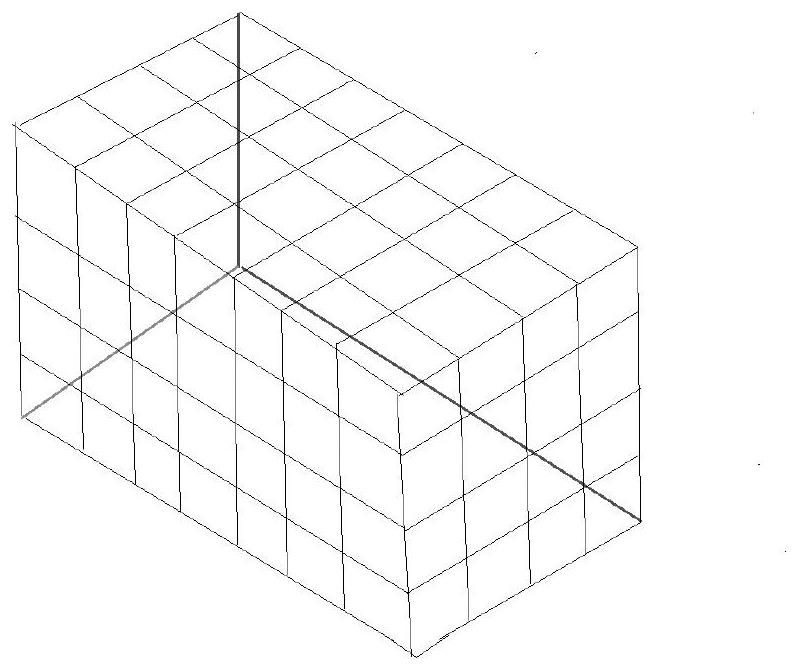

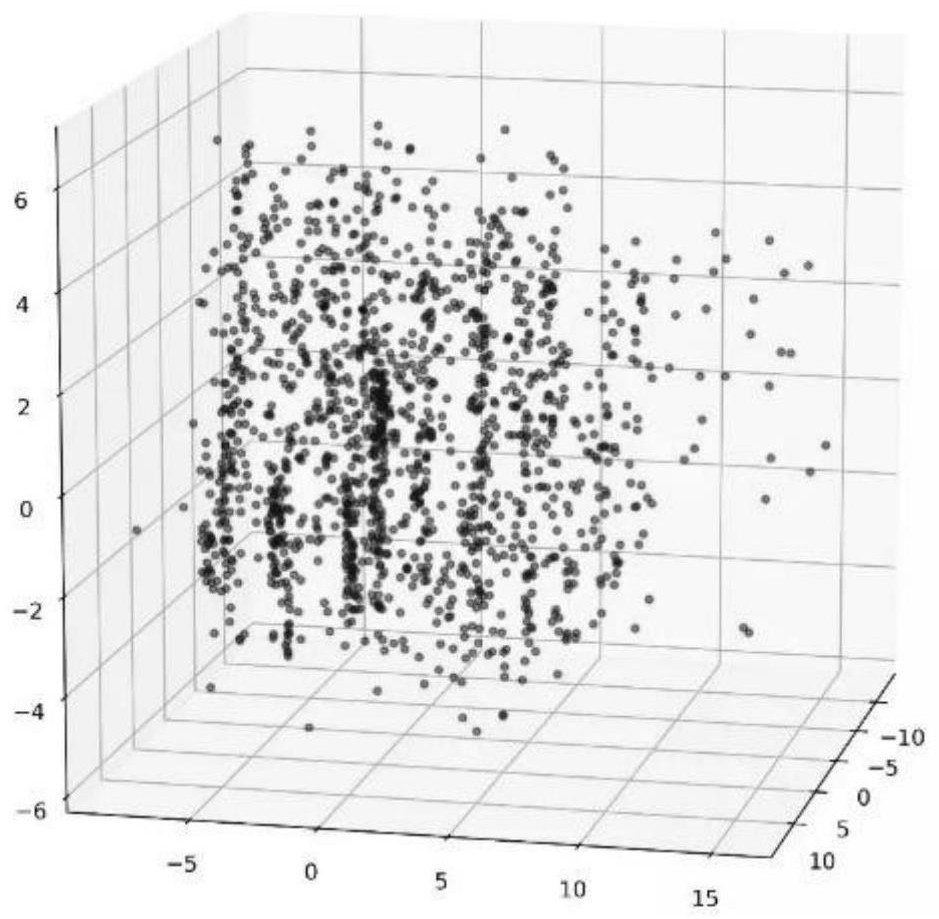

[0021] This application realizes the granulation of coal piles in the coal yard, and mainly involves three processes: loading and unloading at the factory, coal storage and inventory, and loading into the furnace and adding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com