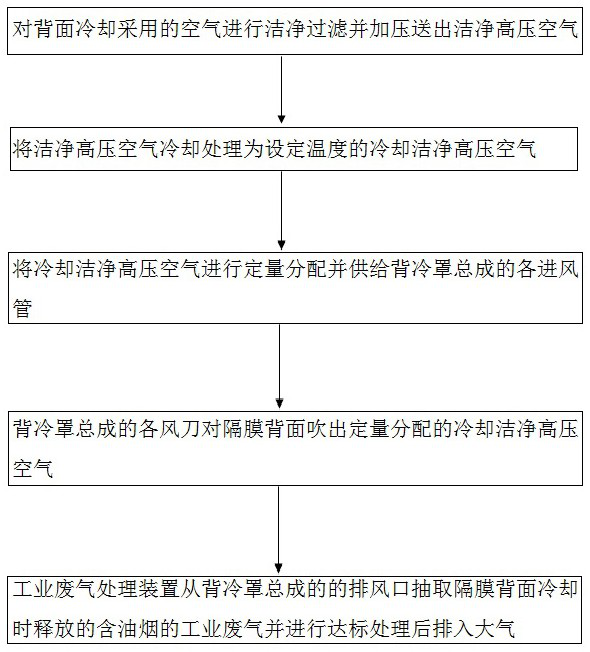

Wet-method lithium battery diaphragm back cooling process

A lithium battery diaphragm and cooling process technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of excessive industrial exhaust fume concentration, high-efficiency cooling, etc. The effect of improving the internal resistance of the diaphragm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

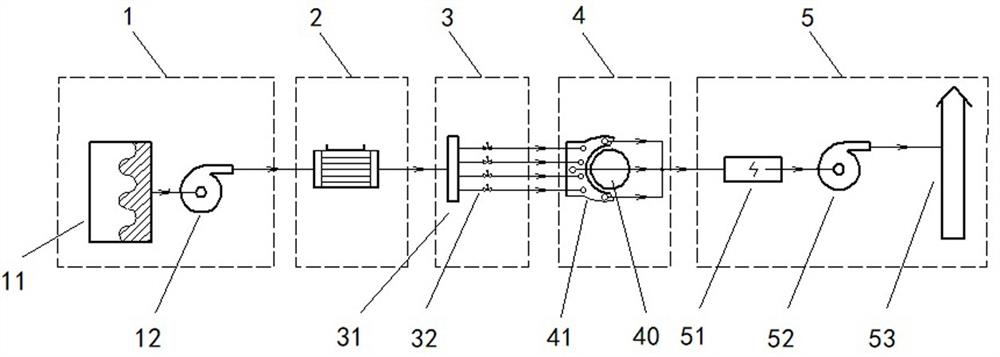

Embodiment 1

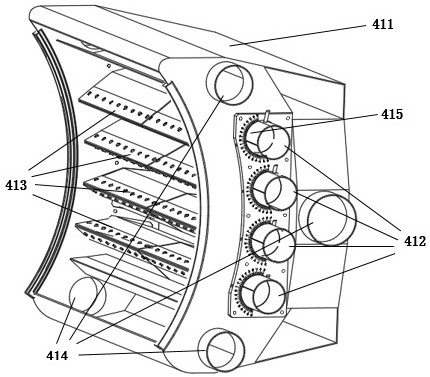

[0065] The filter equipment 11 filters the air, and then sets the air supply volume of a single high-voltage variable frequency air supply fan 12 to 500m³ / h, then cools through the cooling device 2 and supplies constant temperature and quantitative cooling clean high-pressure air through the air volume distribution device 3, and then passes through The diaphragm cooling device 4 performs cooling verification on the back of the diaphragm, and at the same time sets the exhaust air volume of the high-voltage variable frequency exhaust fan 52 to 6500m³ / h, and extracts the industrial waste gas through the exhaust port 414 of the back cooling cover assembly 41, and transports it to the oil fume treatment equipment 51 Purify, discharge through the chimney 53 up to the standard, and finally perform data detection on the peel strength on the back of the diaphragm.

Embodiment 2

[0067] The difference between this embodiment and Embodiment 1 is that in this embodiment, the air supply volume of a single high-voltage variable frequency air supply fan 12 is set to 1000m³ / h, other operations are the same as in Embodiment 1, and then the peel strength on the back of the diaphragm is detected .

Embodiment 3

[0069] The difference between this embodiment and Embodiment 1 is that in this embodiment, the air supply volume of a single high-voltage variable-frequency air supply fan 12 is set to 1500m³ / h, other operations are the same as in Embodiment 1, and then the peel strength on the back of the diaphragm is tested for data .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com