Method for improving quality of tea leaf raw materials through tree abiotic stress

A kind of technology of abiotic stress and green tea, which is applied in the field of abiotic stress on trees to improve the quality of tea green raw materials, can solve the problems of improper control, no production, and influence on tea yield, and achieve large quantity, high versatility, and aroma The effect of rich molecular species

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

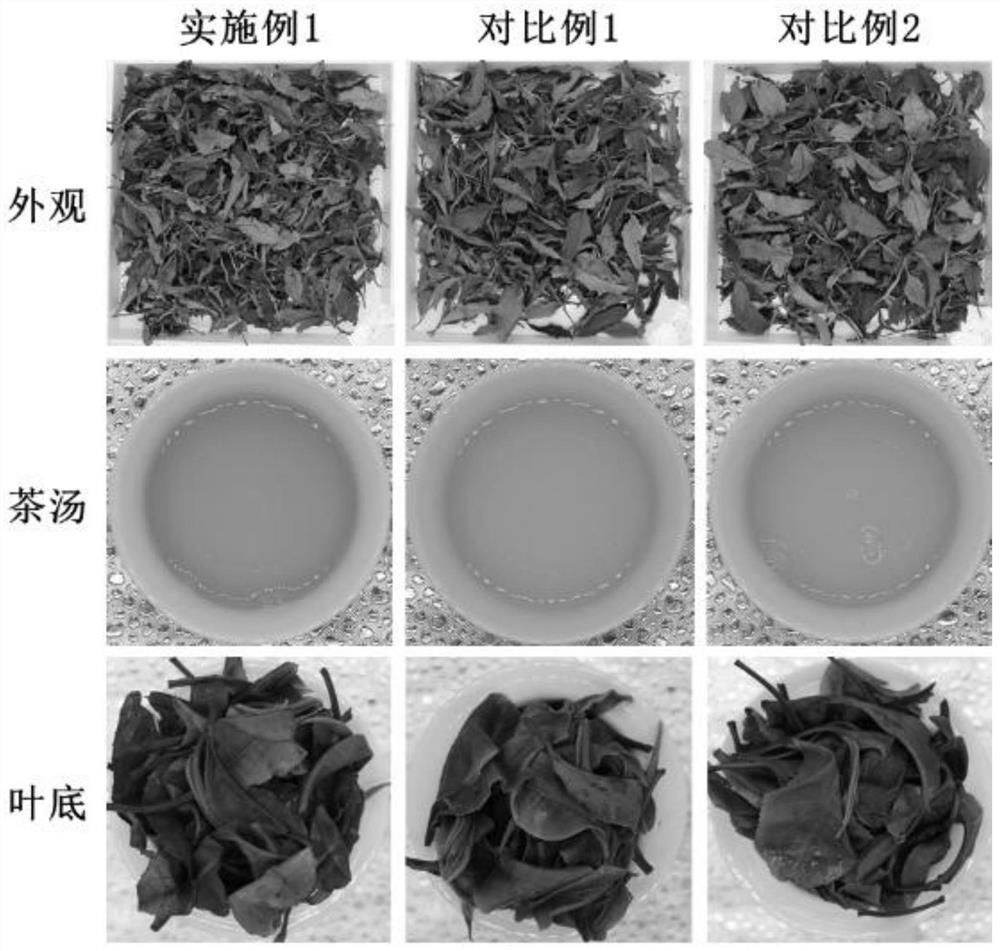

[0025] Embodiment 1 A kind of method of improving the quality of tea green raw material by abiotic stress on tree

[0026] (1) Selection of tea gardens: When it is not raining and the temperature is lower than 38°C, select a flat Yinghong No. 9 tea garden (located at the Provincial Agricultural Science Tea Research Institute, No. 1, Guangcong Town, Zhongluotan Town, Baiyun District, Guangzhou City) base);

[0027] (2) Abiotic stress treatment on trees: Treat at 8:00-11:00 am or 3:00-7:00 pm to avoid morning dew and noon high temperature, use soft materials (such as branches with tender leaves, soft plastics) or cloth strips, etc.) swipe the buds and leaves of the tea tree back and forth, with a light force, so as not to cause the buds and leaves to break, in each area where the tea is processed (that is, within the range of the soft material swept) For 2.5min each treatment, it is advisable that the edges and veins of tender buds and tender leaves appear red, and the buds and...

Embodiment 2

[0030] Embodiment 2 A kind of method that abiotic stress on tree improves the quality of tea green raw material

[0031] (1) Selection of tea gardens: When it is not raining and the temperature is lower than 38°C, select a flat Jinxuan tea garden (located at the Agricultural Science Tea Research Institute Base of Guangcong No. 1, Zhongluotan Town, Baiyun District, Guangzhou City) ;

[0032] (2) Abiotic stress treatment on trees: Treat at 8:00-11:00 am or 3:00-7:00 pm to avoid morning dew and noon high temperature, use soft materials (such as branches with tender leaves, soft plastics) or cloth strips, etc.) swipe the buds and leaves of the tea tree back and forth, with a light force, so as not to cause the buds and leaves to break, in each area where the tea is processed (that is, within the range of the soft material swept) Each treatment is 2min, and it is appropriate that the edges and veins of the tender buds and tender leaves appear red, and the buds and leaves are not s...

Embodiment 3

[0035] Embodiment 3 A kind of method that abiotic stress on tree improves the quality of tea green raw material

[0036] (1) Selection of tea gardens: When it is not raining and the temperature is lower than 38°C, select a flat tea garden of Longjing No. 34 variety (located at the Provincial Agricultural Science Tea Research Institute Base, No. 1, Guangcong Town, Zhongluotan Town, Baiyun District, Guangzhou City) );

[0037](2) Abiotic stress treatment on trees: Treat at 8:00-11:00 am or 3:00-7:00 pm to avoid morning dew and noon high temperature, use soft materials (such as branches with tender leaves, soft plastics) or cloth strips, etc.) swipe the buds and leaves of the tea tree back and forth, with a light force, so as not to cause the buds and leaves to break, in each area where the tea is processed (that is, within the range of the soft material swept) Each treatment for 3 minutes, it is advisable that the edges and veins of tender buds and tender leaves appear red, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com