Soybean milk treatment method, bean-based yogurt and bean-based yogurt preparation method

A treatment method, technology of soy-based acid, applied to bacteria, dairy products, streptococcus/lactococcus used in food preparation, etc., can solve the problems of strong beany smell and poor taste, and achieve mellow and strong bean flavor, easy operation Convenience, liking-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

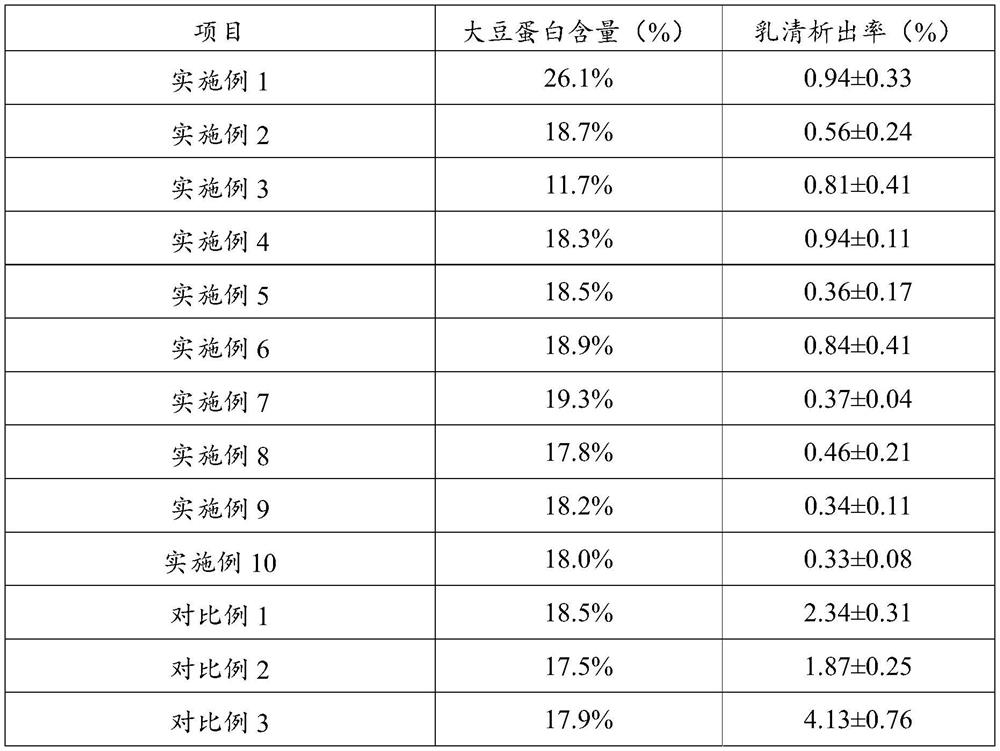

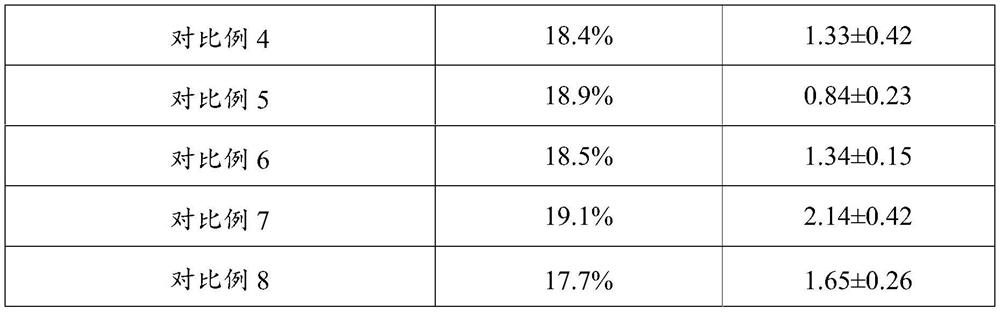

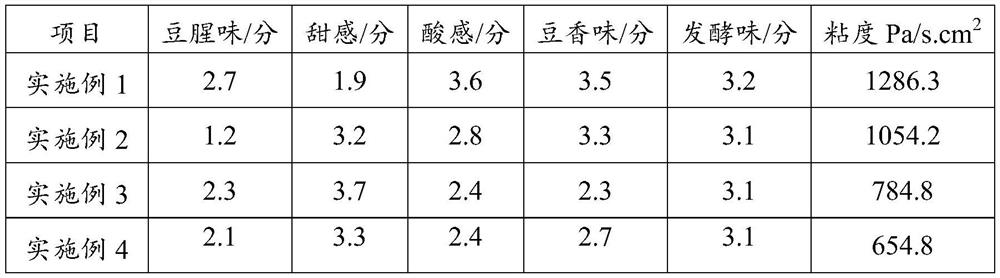

Examples

Embodiment 1

[0044] The present embodiment provides a kind of processing method of soya-bean milk, comprises the steps:

[0045] Select non-transgenic, worm-free high-quality soybeans as soybean raw materials, soak 100kg of soybeans in 400kg of water for 6 hours, peel off the skin (requires peeling rate ≥ 70%, crude protein content of peeled soybeans ≥ 39%), add 500kg of water through grinding, temperature Cook the pulp at 105°C for 5 minutes, and filter it through a common membrane to obtain soybean milk. According to the mass ratio of soybean milk and maltose of 1:0.5, mix soybean milk and maltose syrup to obtain a mixed slurry, and use attapulgite-filled The chromatographic column and the chromatographic column filled with activated carbon absorb the mixed slurry to obtain the treated soybean milk.

[0046] This embodiment also provides a soy-based yogurt and a preparation method thereof. Based on the total mass of soy-based yogurt being 100kg, the raw materials include soybean polysacc...

Embodiment 2

[0051] The present embodiment provides a kind of processing method of soya-bean milk, comprises the steps:

[0052] Select non-transgenic non-worm eye high-quality soybeans as raw materials, soak 100kg of soybeans in 400kg of water for 6h, peel off (require peeling rate ≥ 70%, crude protein content of peeled soybeans ≥ 39%), add 500kg of water through grinding, the temperature is Boil the pulp at 105°C for 5 minutes, and filter it through a common membrane to obtain soybean milk. According to the mass ratio of soybean milk and maltose of 1:1, mix soybean milk and maltose syrup to obtain a mixed slurry, and use a layer filled with attapulgite An analytical column and a chromatographic column filled with activated carbon absorb the mixed slurry to obtain the treated soybean milk.

[0053] This embodiment also provides a soy-based yogurt and a preparation method thereof. Based on the total mass of soy-based yogurt being 100kg, the raw materials include soybean polysaccharide: 1.1...

Embodiment 3

[0058] The present embodiment provides a kind of processing method of soya-bean milk, comprises the steps:

[0059] Select non-transgenic non-worm eye high-quality soybeans as raw materials, soak 100kg of soybeans in 400kg of water for 6h, peel off (require peeling rate ≥ 70%, crude protein content of peeled soybeans ≥ 39%), add 500kg of water through grinding, the temperature is Boil the pulp at 105°C for 5 minutes, and filter it through a common membrane to obtain soybean milk. According to the mass ratio of soybean milk and maltose of 1:1.5, mix soybean milk and maltose syrup to obtain a mixed slurry, and use a layer filled with attapulgite An analytical column and a chromatographic column filled with activated carbon absorb the mixed slurry to obtain the treated soybean milk.

[0060] This embodiment also provides a soy-based yogurt and a preparation method thereof. Based on the total mass of soy-based yogurt being 100kg, the raw materials include soybean polysaccharide: 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com