Preparation method of lipidosome with stable effective component coating capacity

A liposome and liposome suspension technology, which is applied in the directions of food ingredients, food forming, food science, etc., can solve the problems affecting the absorption rate and absorption speed, etc. The effect of improving the bioabsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

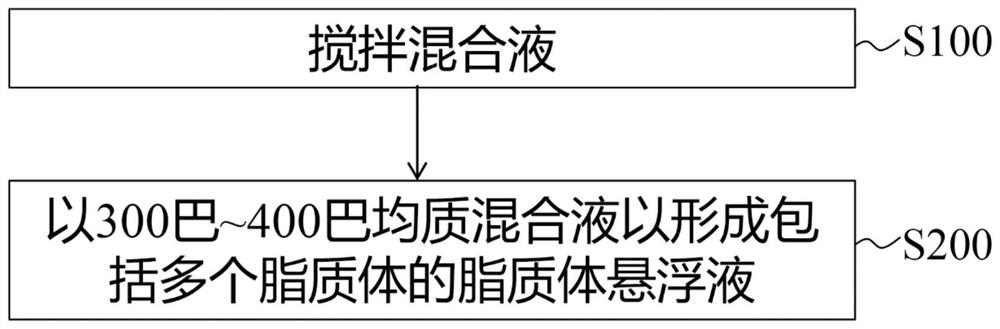

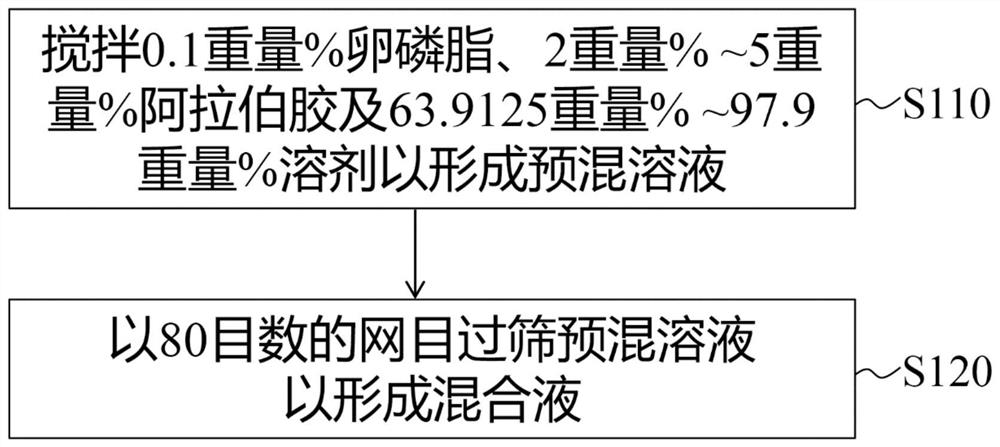

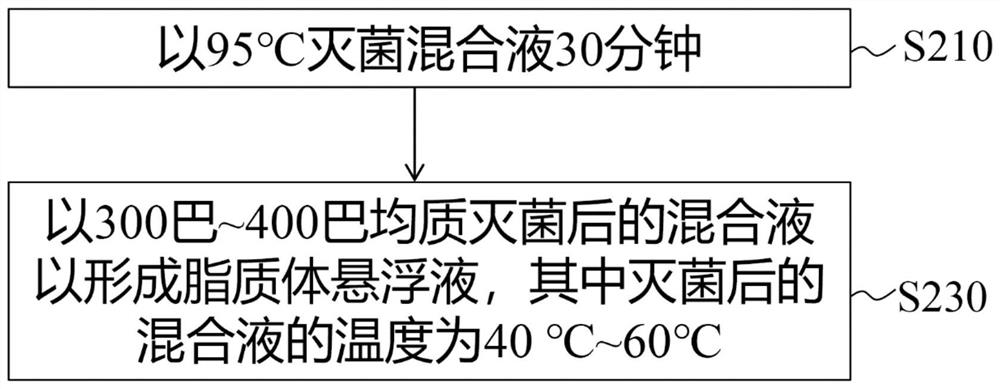

Method used

Image

Examples

example 1

[0077] Example 1: Preparation of liposome 1 containing vitamin C (pre-killing treatment)

[0078] Here, 6 groups of mixed liquids were prepared according to the formula ingredients and formula ratios in Table 1. Among them, the control group is group C1 to group C4, and the experimental group is group E1 to group E2. In addition, the sterilization procedure of groups C1 to C4 and groups E1 to E2 is carried out before homogenization. In other words, the preparation process of groups C1 to C4 and groups E1 to E2 is pre-killing treatment.

[0079] Table 1

[0080]

[0081] Here, the total weight of the mixed solution is 100 grams. Firstly, soybean lecithin was mixed with part of water at a weight ratio (w / w) of 1:50, and stirred at room temperature (25° C.) to confirm that lecithin was dissolved in part of the water to form a first premixed solution. And, mix Arabic gum, Guanhua bean gum, sanxian gum, sucralose, potassium hexadienoate, vitamin C and the rest of water to fo...

example 2

[0083] Example 2: Preparation of liposome 1 containing vitamin C (post-killing treatment)

[0084] Here, 6 groups of mixed liquids were prepared according to the formula ingredients and formula ratios in Table 2. Wherein, the control group is group C5 to group C8, and the experimental group is group E3 to group E4. In addition, the sterilization procedures of groups C5 to C8 and groups E3 to E4 are carried out after homogenization. In other words, the preparation process of groups C5 to C8 and groups E3 to E4 is post-killing treatment.

[0085] Table 2

[0086]

[0087] Here, the total weight of the mixed solution is 100 grams. Firstly, soybean lecithin was mixed with part of water at a weight ratio of 1:50 (w / w), and stirred at room temperature (25° C.) to confirm that lecithin was dissolved in part of the water to form a first premixed solution. And, mix Arabic gum, Guanhua bean gum, sanxian gum, sucralose, potassium hexadienoate, vitamin C and the rest of water to fo...

example 3

[0089] Example 3: Stability test of liposome 1

[0090] Here, each group of liposome suspensions prepared in Example 1 and each group of liposome suspensions prepared in Example 2 were left to stand for one day at room temperature (25° C.) to observe whether there was stratification in the liposome suspension . Moreover, if the liposome suspension is a uniform non-layered liquid, it means that the liposome 1 structure in it is relatively stable. On the contrary, if the liposome suspension has obvious stratification and the color is turbid and uneven, it means that the structure of the liposome 1 contained in it is relatively unstable. In other words, since the coating layer 10 of the liposome 1 is broken, the liposome 1 is not formed, and the liposome suspension is clearly stratified.

[0091] see Figure 8 . The liposome suspensions of the C1 group and the C3 group produced obvious stratification, which represented that when the mixed solution contained 1% by weight of so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com