Gas-liquid-solid three-phase cyclone separation device with automatic exhaust valve and separation method thereof

A technology of cyclone separation device and automatic exhaust valve, applied in separation method, fluid pressure actuation device, filtration separation, etc., can solve the problems of difficult to clean and reuse, no gas removal function, short service life of filter element, etc. , to achieve the effect of facilitating overall separation, improving separation stability and efficiency, and reducing replacement frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

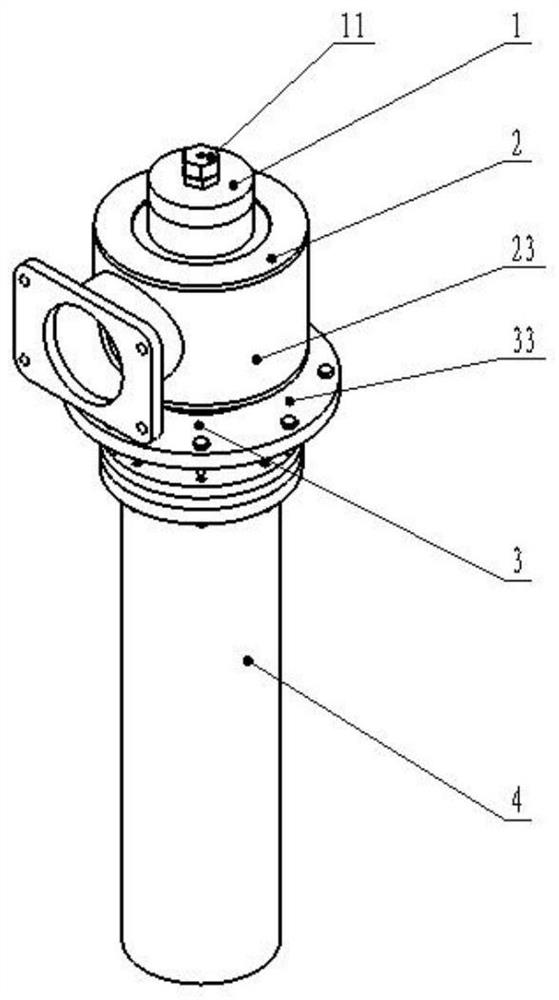

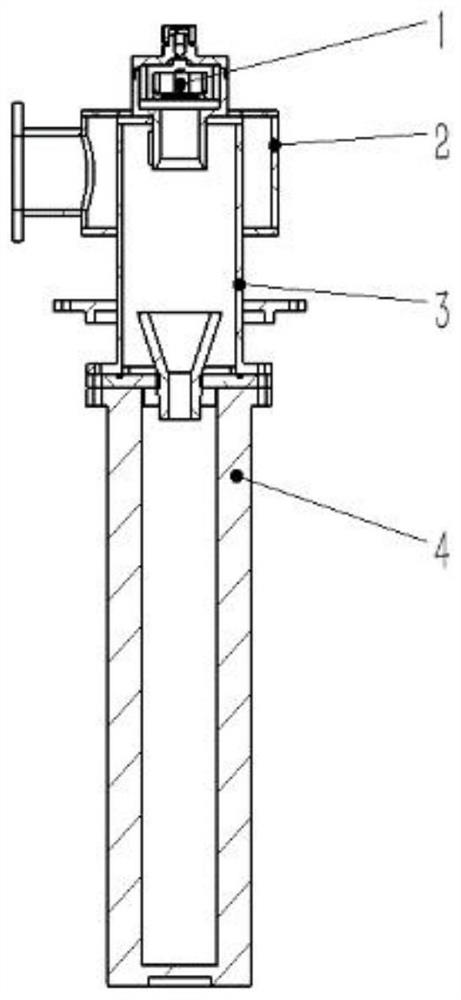

[0038] Gas-liquid-solid three-phase cyclone separation device with automatic exhaust valve, such as figure 1 and combine figure 2As shown, including the automatic exhaust valve 1, the oil return distribution chamber 2, the cyclone main body 3 and the filter element 4, the materials of the cyclone main body 3, the oil return distribution chamber 2 and the automatic exhaust valve 1 should be selected from high-strength aluminum Guaranteed anti-corrosion, anti-oxidation and lightweight. The oil return distribution chamber 2 is located at the lower end of the automatic exhaust valve 1, the upper top plate 22 of the head in the oil return distribution chamber 2 is connected with the lower end of the lower housing 13 of the exhaust valve in the automatic exhaust valve 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com