Water mist spraying smoke treatment equipment

A technology for processing equipment and smog, which can be applied in separation methods, use of liquid separation agents, and dispersed particle separation, etc., and can solve the problems of potential safety hazards and high costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

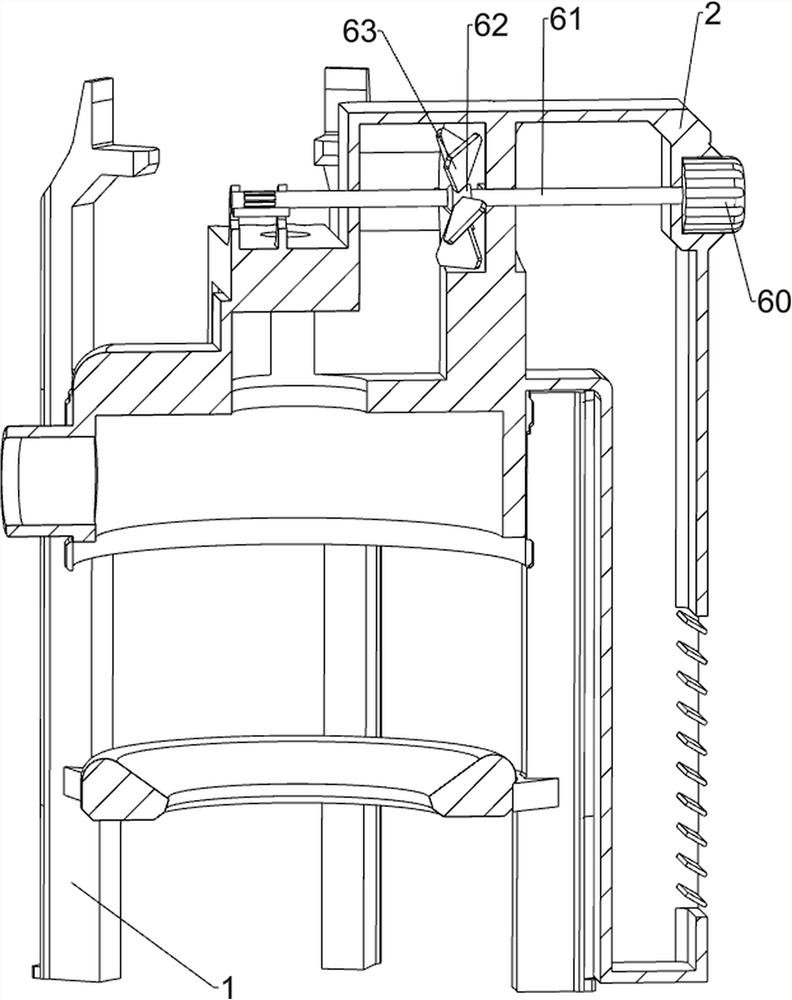

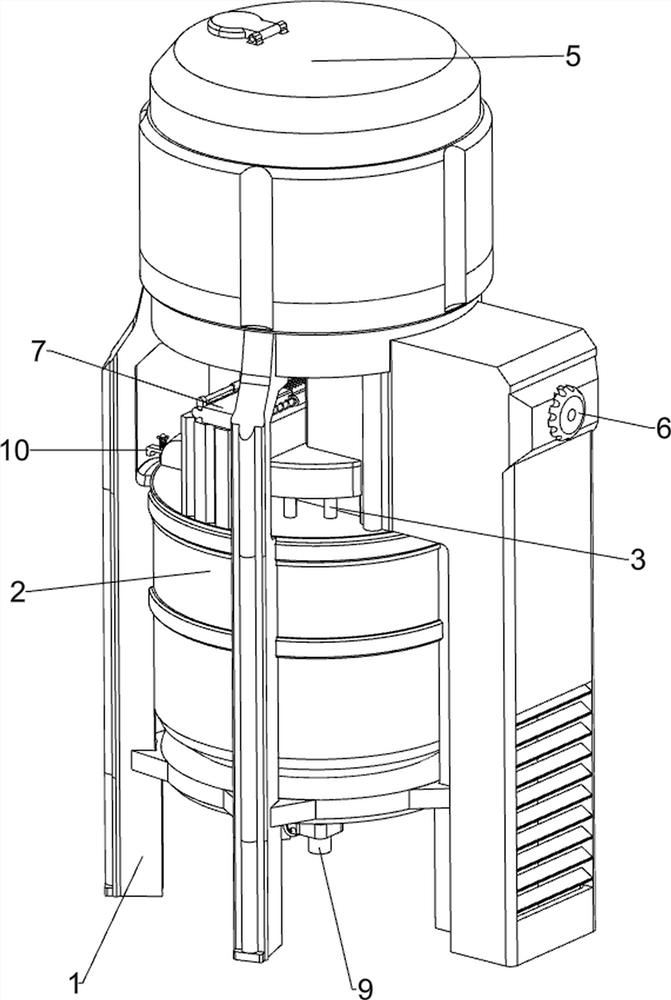

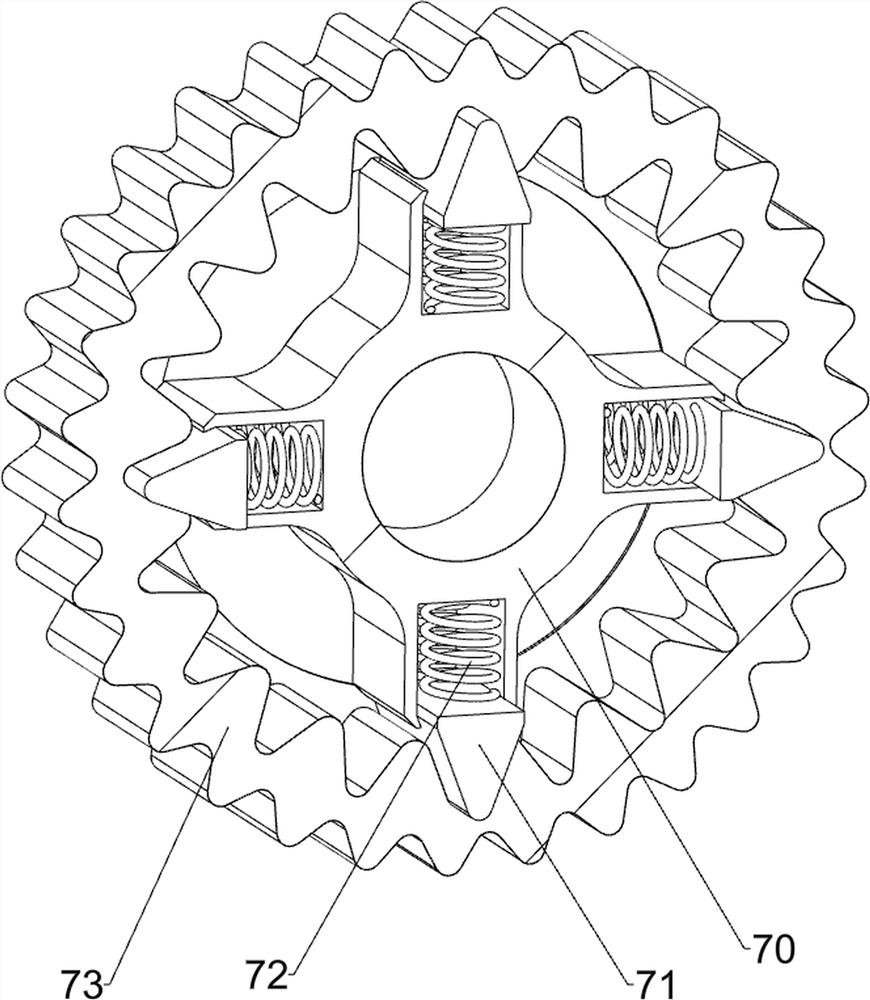

[0035] A water mist spray smoke treatment equipment, such as Figure 1-15 As shown, it includes a support frame 1, a mounting bracket 2, a feed pipe 21, a guide tube 3, a nozzle 4, a storage mechanism 5 and an air suction mechanism 6, and the support frame 1 is provided with a mounting bracket 2, and the left side of the mounting bracket 2 The feed pipe 21 is fixedly connected in the middle, and the guide tube 3 is fixedly connected in the middle of the installation bracket 2. The front and rear guide tubes 3 are distributed equidistantly. The nozzles 4 are evenly distributed in an arc shape, the support frame 1 is provided with a storage mechanism 5, and the mounting bracket 2 is provided with an air suction mechanism 6.

[0036] The storage mechanism 5 includes a water storage cylinder 50, a first rotating shaft 51, a cylinder cover 52, a first conduit 53 and a diverter box 54. The top of the support frame 1 is fixedly connected with the water storage cylinder 50, and the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com