A kind of cellulose/chitosan composite bead and its preparation method and application

A technology of cellulose and chitosan, applied in chemical instruments and methods, alkali metal compounds, and other chemical processes, can solve the problems of chitosan being dissolved in acid and poor mechanical strength, so as to achieve high solubility and reduce production costs , The effect of saving resources and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

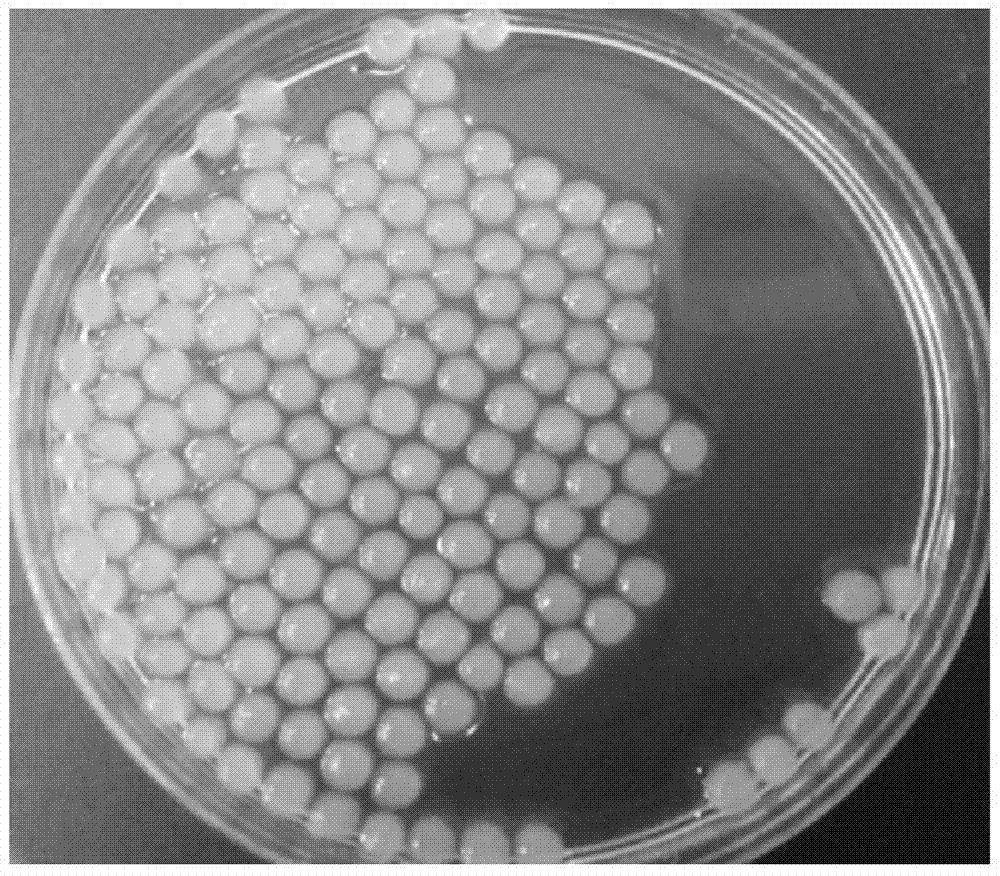

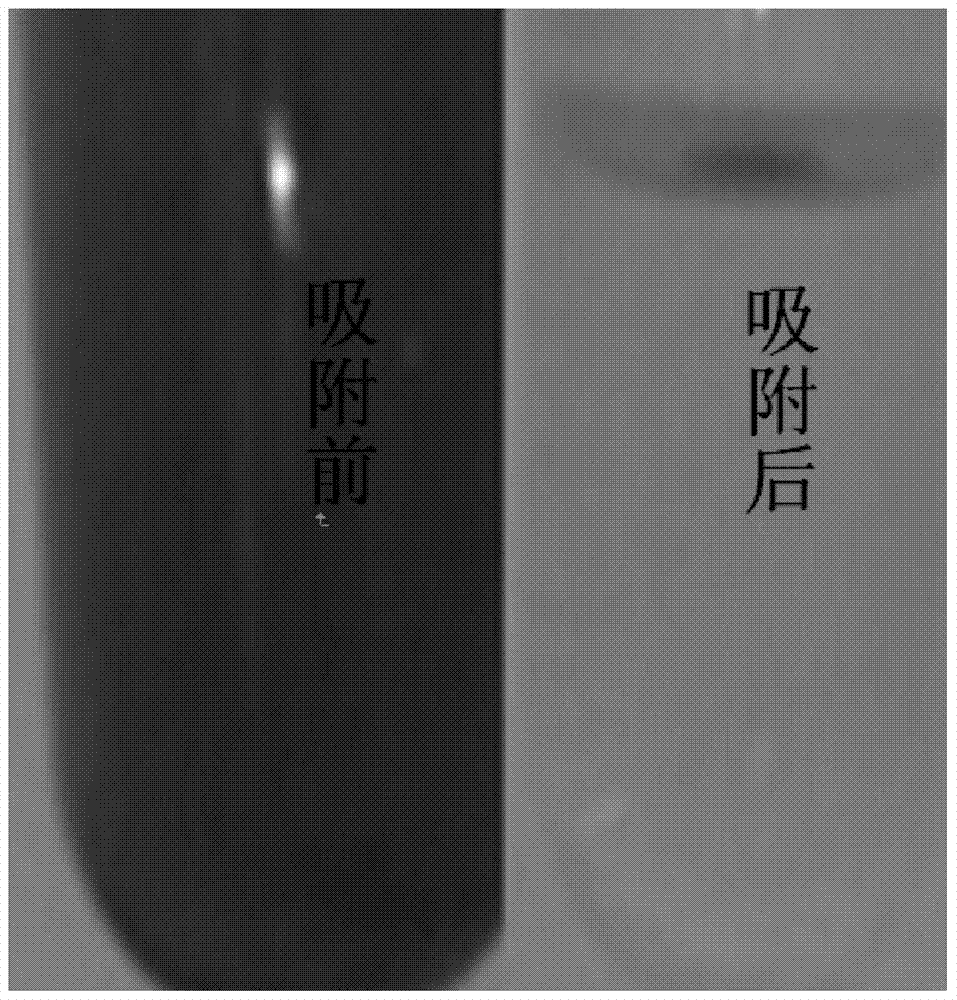

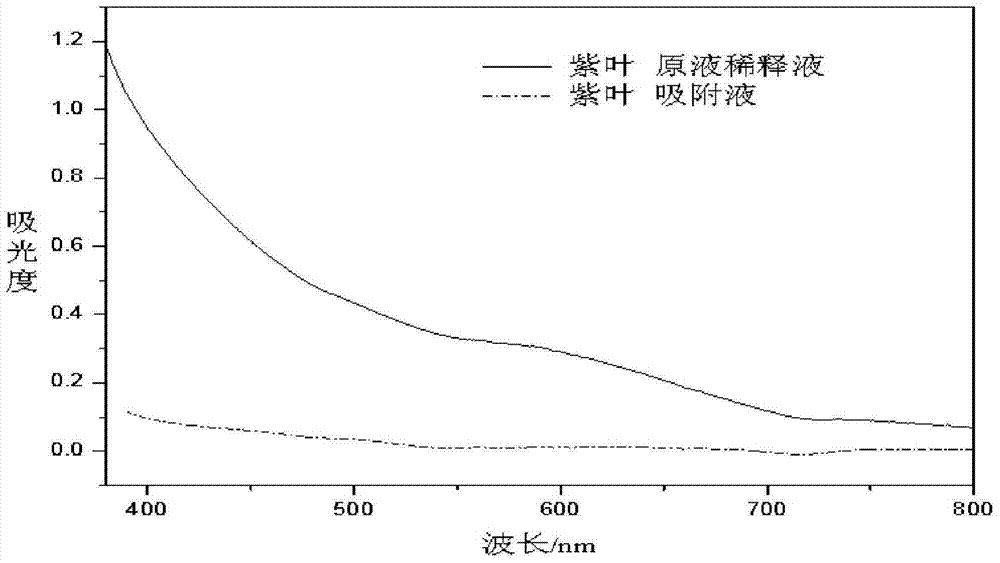

[0041] A kind of cellulose / chitosan composite pellet, its preparation method is as follows:

[0042] (1) Dissolve 1.0g of α-cellulose in 20g of ionic liquid 1-ethyl-3-methylimidazolium acetate ([Emim]Ac) in a conical flask, and stir magnetically for 3 hours in an oil bath at 110°C Completely dissolve the cellulose to obtain a transparent cellulose solution;

[0043] (2) In another conical flask, dissolve 1.0g of chitosan in 20g of ionic liquid 1-ethyl-3-methylimidazole acetate ([Emim]Ac), and stir magnetically in an oil bath at 70°C 2h makes chitosan dissolve completely, obtains transparent chitosan solution;

[0044] (3) Mix the above-mentioned cellulose dissolving solution with the chitosan dissolving solution, and stir magnetically for 1 hour under an oil bath at 110° C. until it becomes a pale yellow uniform mixed solution;

[0045] (4) Pack the obtained mixed solution into a medical syringe, then push the mixed solution into an absolute ethanol coagulation bath to obtai...

Embodiment 2

[0051] A kind of cellulose / chitosan composite pellet, its preparation method is as follows:

[0052] (1) Dissolve 0.5g of α-cellulose in 20g of ionic liquid 1-butyl-3-methylimidazolium chloride ([Bmim]Cl) in a conical flask, and stir magnetically for 3.5 hours in an oil bath at 100°C. h completely dissolves the cellulose to obtain a transparent cellulose solution;

[0053] (2) In another conical flask, dissolve 1.0g of chitosan in 20g of ionic liquid 1-butyl-3-methylimidazolium chloride ([Bmim]Cl), stir with magnetic force under 80°C oil bath 1.5h makes chitosan dissolve completely, obtains transparent chitosan solution;

[0054] (3) Mix the above-mentioned cellulose dissolving solution with the chitosan dissolving solution, and stir magnetically for 1 hour in an oil bath at 120° C. until it becomes a pale yellow uniform mixed solution;

[0055] (4) The obtained mixed solution is packed into a medical syringe, and then the mixed solution is pushed into a deionized water coag...

Embodiment 3

[0060] A kind of cellulose / chitosan composite pellet, its preparation method is as follows:

[0061] (1) Dissolve 0.3g of α-cellulose in 20g of ionic liquid 1-ethyl-3-methylimidazolium acetate ([Emim]Ac) in a conical flask, stir magnetically for 3.5 h completely dissolves the cellulose to obtain a transparent cellulose solution;

[0062] (2) In another conical flask, dissolve 0.6g of chitosan in 15g of ionic liquid 1-ethyl-3-methylimidazole acetate ([Emim]Ac), under 90°C oil bath, magnetically stir 1h makes chitosan dissolve completely, obtains transparent chitosan solution;

[0063] (3) Mix the above-mentioned cellulose dissolving solution with the chitosan dissolving solution, and stir magnetically for 1.5 h in an oil bath at 110° C. until it becomes a pale yellow uniform mixed solution;

[0064] (4) The obtained mixed solution is packed into a medical syringe, and then the mixed solution is pushed into a DMSO coagulation bath to obtain a gel-state composite bead; the prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com