Solid-liquid cyclone and device and method for producing paraxylene

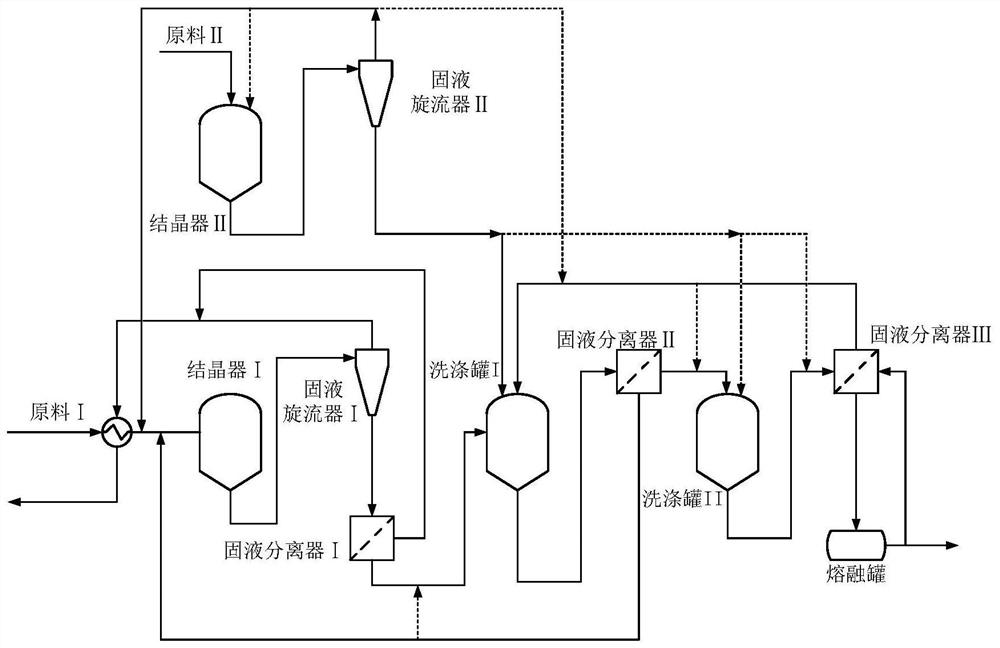

A technology of p-xylene and cyclone, which is applied in the direction of cyclone device, the device whose axial direction of the cyclone can be reversed, chemical instruments and methods, etc., can solve the problem that the recovery rate needs to be improved, the separation effect is not good, and the device price Expensive and other issues, to achieve the effect of less product loss, high separation effect, and reduce crystal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

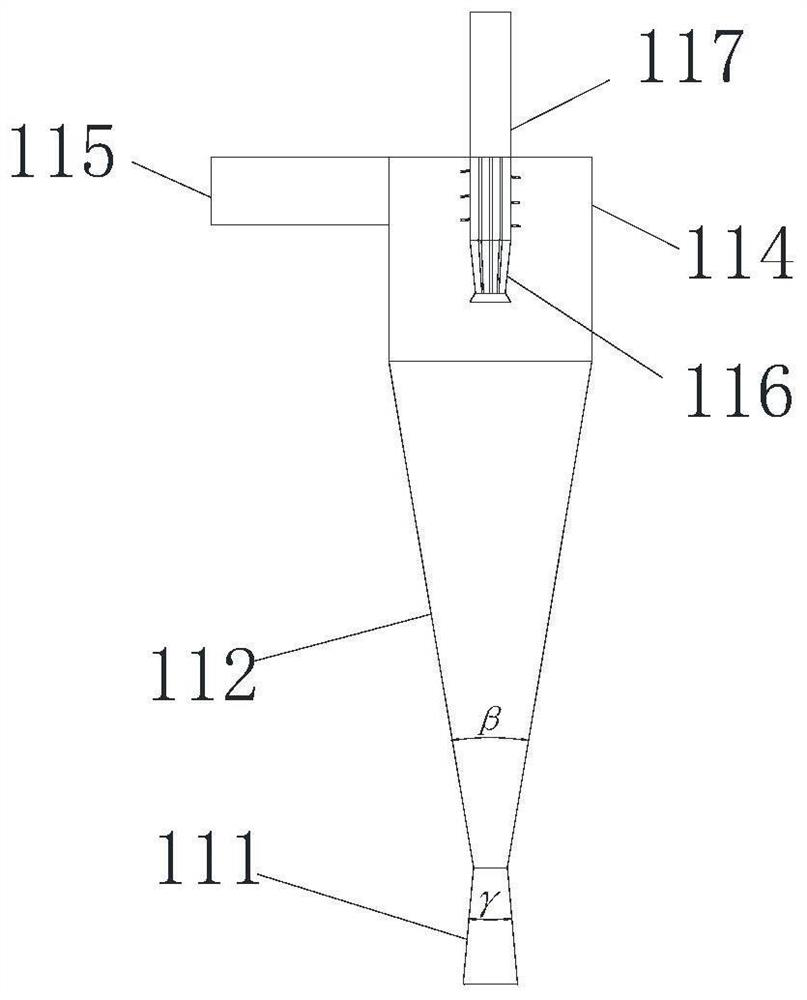

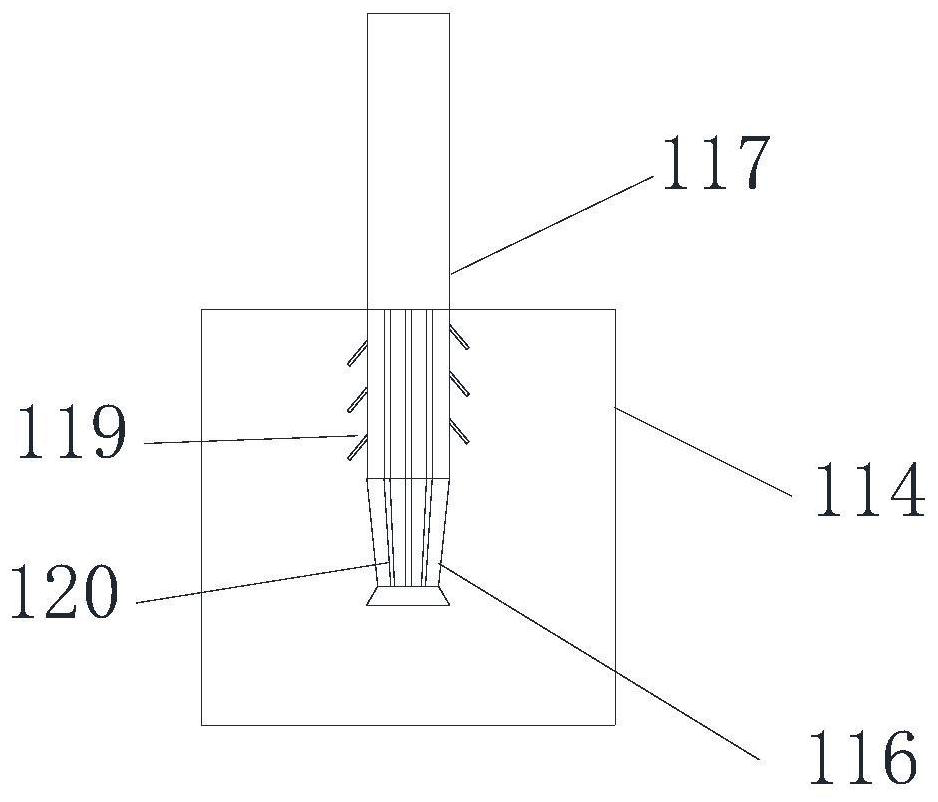

[0086] use as figure 2 As shown in the solid-liquid cyclone, the solid-liquid cyclone includes a cyclone separator bottom flow pipe 111, a cone separation section 112, and a cylindrical separation section 114 provided with a cyclone inlet 115, which are sequentially connected from bottom to top, The top of the primary overflow pipe 116 communicates with the bottom of the secondary overflow pipe 117, and the primary overflow pipe 116 is arranged inside the cylindrical separation section 114, and the secondary overflow pipe 117 is arranged outside the cylindrical separation section 114, The surface of the primary overflow pipe 116 is provided with a plurality of guide vanes 119, and the material to be separated containing solid and liquid enters the cylindrical separation section 114 from the cyclone inlet 115, and the liquid enters from the bottom of the primary overflow pipe 116 and flows from the secondary The top of the overflow pipe 117 flows out of the solid-liquid cyclon...

Embodiment 2

[0089] According to the solid-liquid cyclone of embodiment 1, the difference is that the primary overflow of the first frustum-shaped cylinder, the second frusto-conical cylinder and the third cylinder of embodiment 1 that are connected in sequence from bottom to top The flow tube 116 is replaced by a cylinder, the height of which is the sum of the first frustum-shaped cylinder, the second frusto-conical cylinder and the third cylinder in embodiment 1, and the diameter of the cylinder is the first frustum-shaped cylinder in embodiment 1. The diameter of the three barrels.

Embodiment 3

[0091] According to the solid-liquid cyclone of Embodiment 1, the difference is that the guide vane 119 is obliquely downward, and the acute angle between the longitudinal section of the guide vane 119 and the horizontal plane is 80°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size distribution range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com