Intelligent manufacturing and forming integrated device for machining

A mechanical processing and intelligent technology, applied in metal processing equipment, forging/pressing/hammer devices, forging/pressing/hammering machines, etc., can solve problems such as smashing workers, increasing workers' labor pressure, and increasing dangerous accidents. Achieve the effect of improving efficiency, safe and convenient use, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

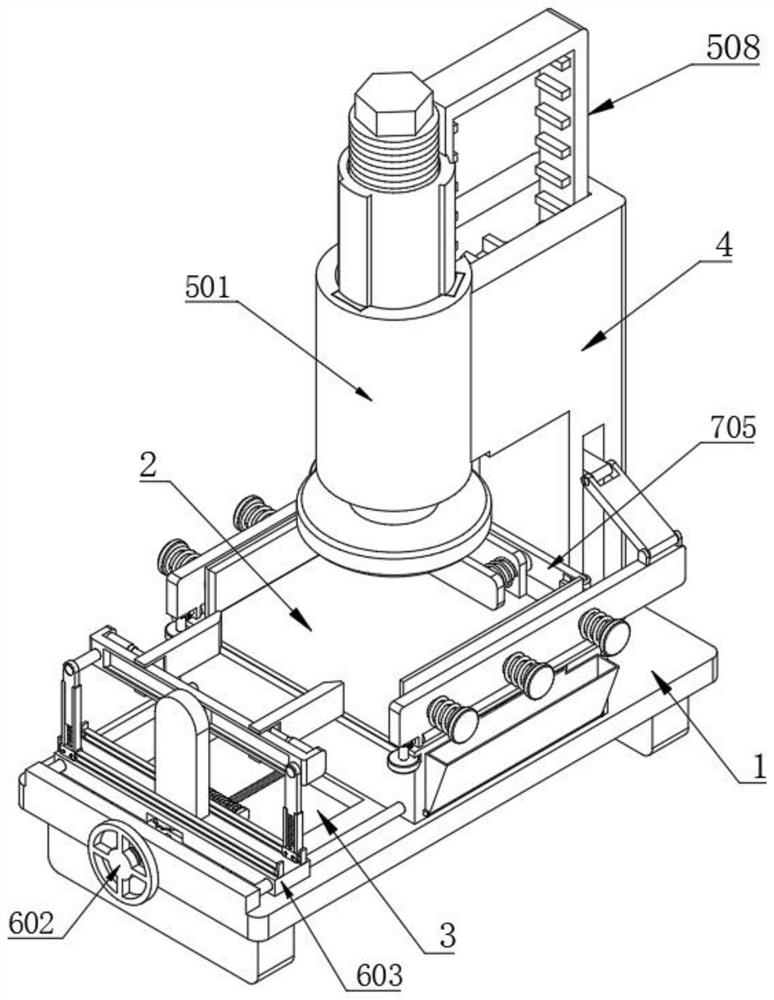

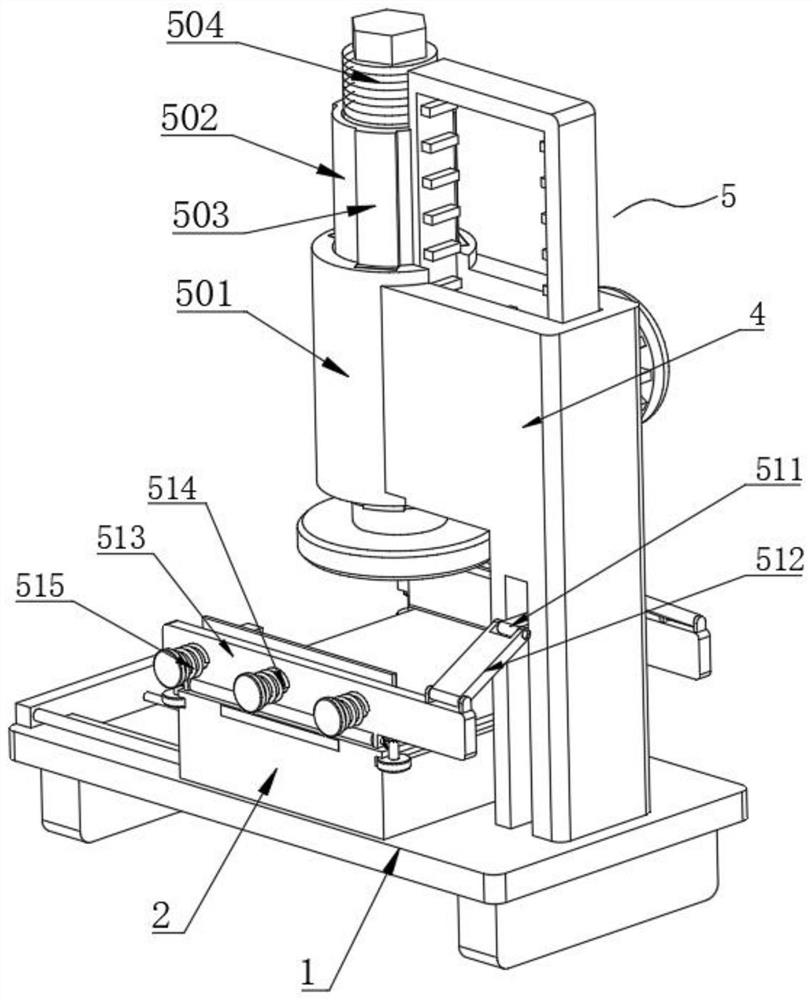

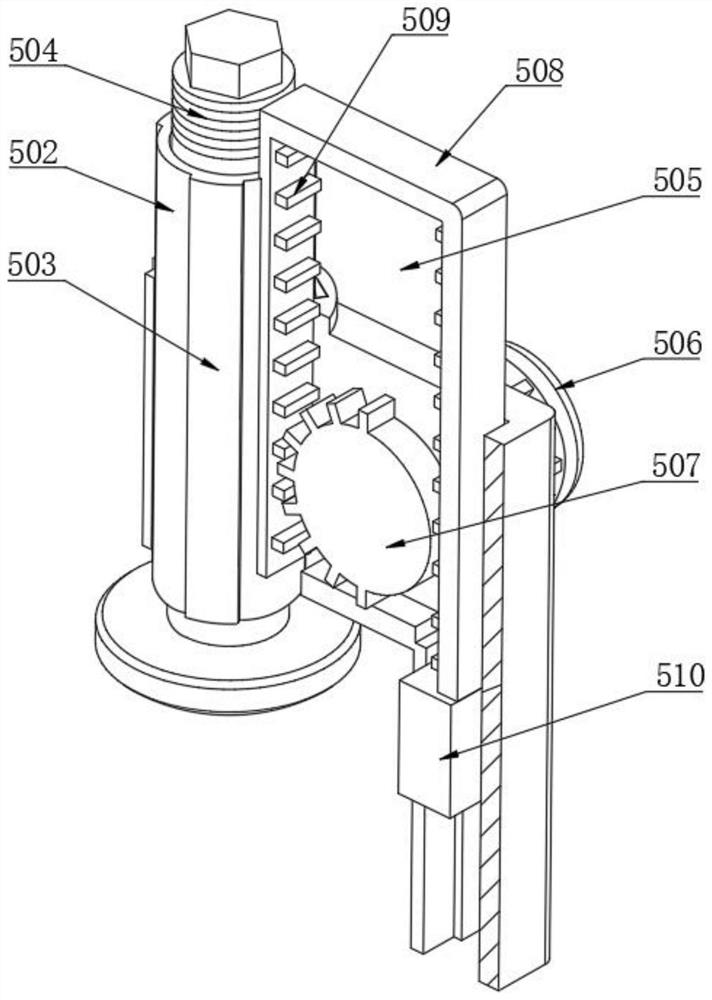

[0035] Example: such as Figure 1-7 As shown, the present invention provides a technical solution, an intelligent manufacturing and forming integrated device for mechanical processing, including:

[0036] The clamping and rotating mechanism 6 can clamp the plate and at the same time turn the plate over to facilitate beating on the back of the plate;

[0037] The forging and clamping anti-deviation mechanism 5 is used for beating and forging small plates, and at the same time, can beat and clamp the sides of the plates;

[0038] The auxiliary clamping and cleaning mechanism 7 blocks the plate, so that the plate can be limited during clamping, preventing the plate from being pushed out of the forging table 2, and can clean and collect debris;

[0039] A forging table 2 is clamped at the middle part of the top of the base 1, one end of the forging table 2 is fixedly connected with a fixed plate 4 by bolts, the other end of the forging table 2 is provided with a movable groove 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com