Special cement mortar production process

A production process and technology for special cement, applied in the field of special cement mortar production process, can solve the problems of increased material application, waste, internal and external cracks on the surface of the mortar, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

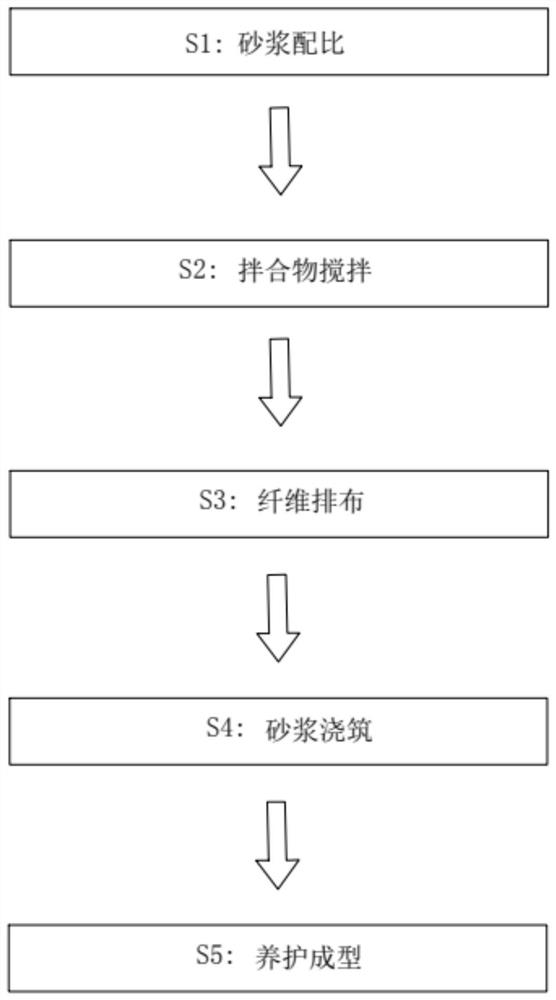

[0024] Such as Figure 1 to Figure 5 Shown, a kind of special cement mortar production process comprises the steps:

[0025] S1: Mortar ratio: Mortar ratio materials include cement and fly ash, ground slag powder or stone powder, fiber materials, sand, water, and admixtures;

[0026] S2: Stirring of the mixture: mixing and stirring the mortar mixture through the mixing station 1, the stirring environment temperature is 6°C-40°C, and the stirring time is 50-100 seconds;

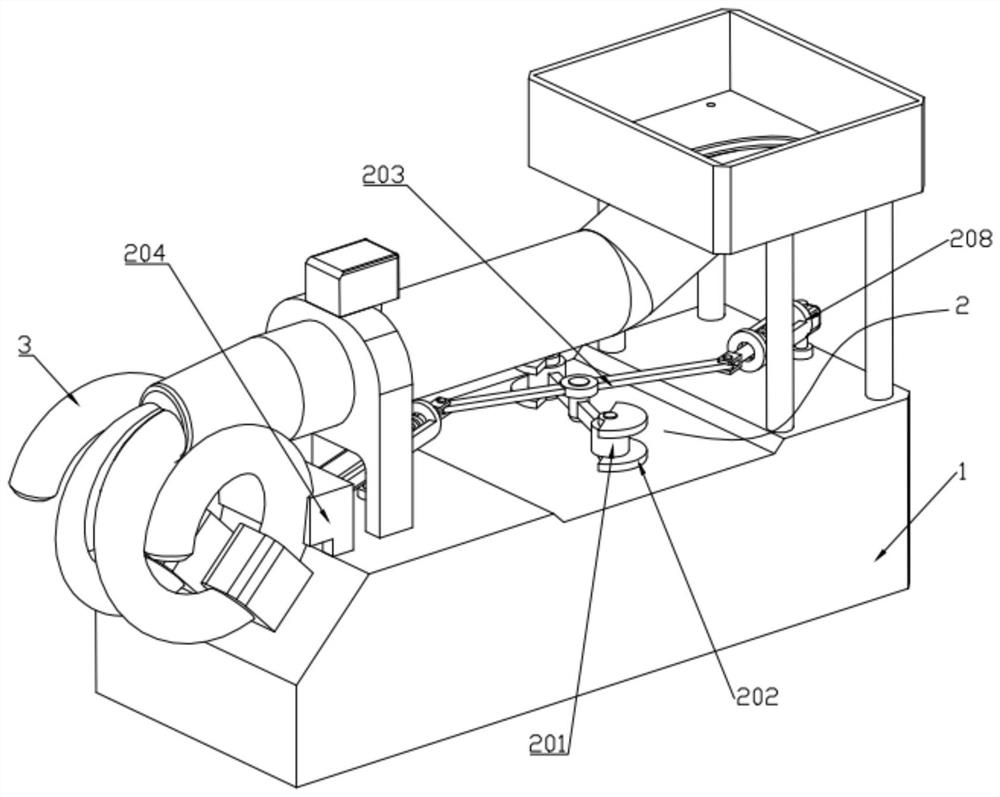

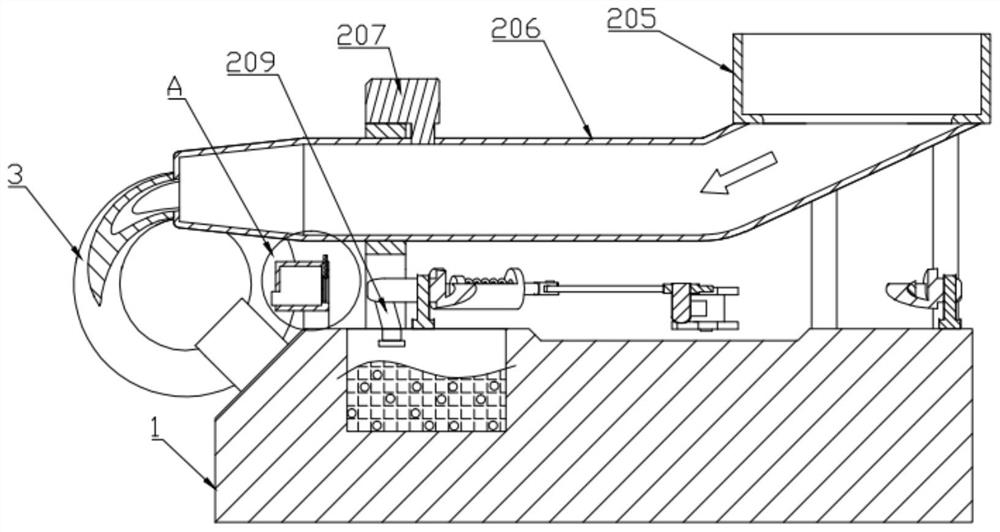

[0027] S3: Fiber arrangement: The mixing station 1 is equipped with a staggered extrusion mechanism 2, through which the staggered extrusion mechanism 2 injects the mortar and fiber filaments into the spiral extruded part 3 alternately, and the slurry is spirally stirred and mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com