Large-flow cryogenic gas bearing turbo expander

A turboexpander and gas bearing technology, which is applied in the field of expanders, can solve the problems such as the decrease of expansion efficiency and the temperature of the main shaft of the expander, and achieve the effect of speeding up the maintenance efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

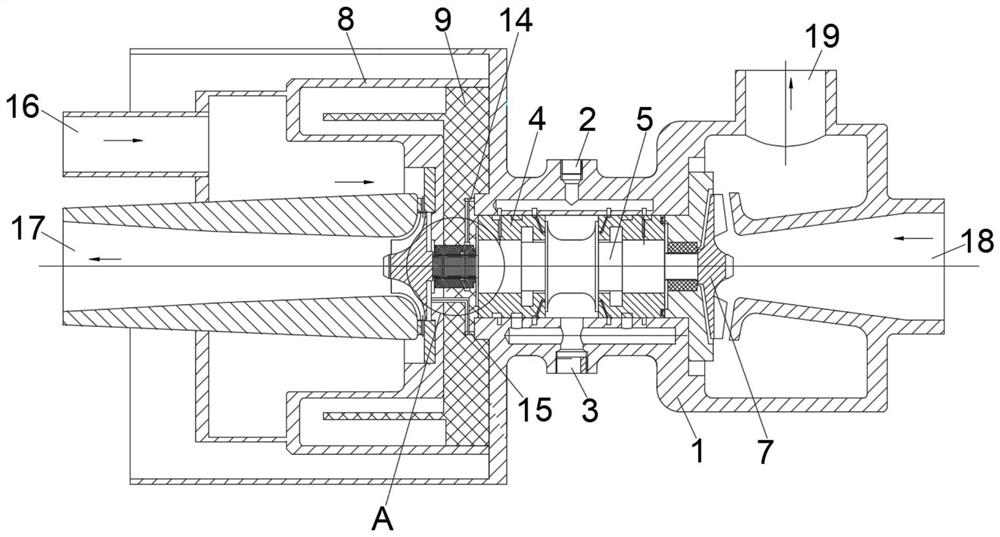

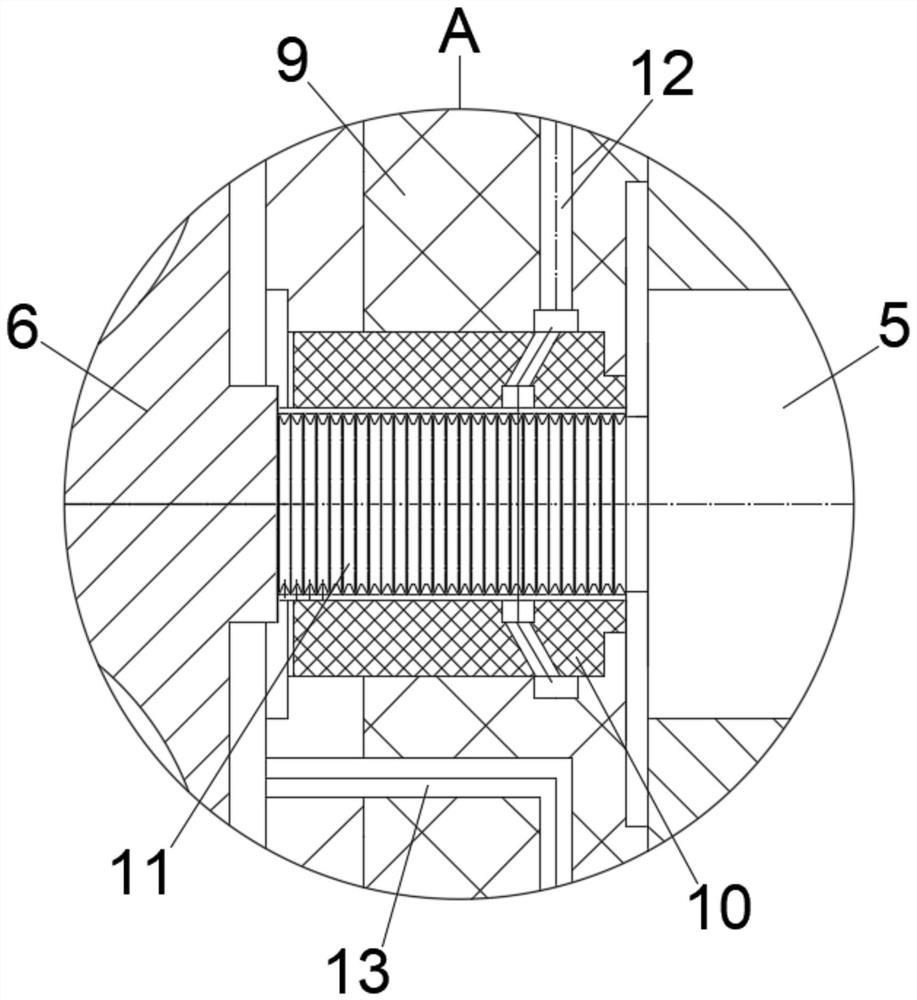

[0052] see Figure 1-2 As shown, a large-flow cryogenic gas bearing turbo expander includes a casing 1, the top surface and the bottom surface of the center of the casing 1 are respectively provided with a bearing gas inlet 2 and a bearing gas outlet 3, and the center of the casing 1 is provided with a bearing gas inlet 2 and a bearing gas outlet 3. The inner wall is provided with two symmetrical support bearings 4, and the inner rings of the two support bearings 4 are movably connected with a main shaft 5, and the two ends of the main shaft 5 are respectively installed with an expansion impeller 6 and a compression impeller 7, and the housing 1 is close to the expansion impeller The inner wall of one side of 6 is provided with a heat-insulating sealing plate 8, and the heat-insulating sealing plate 8 forms a heat-insulating sealing cavity with the inner wall of the housing 1, and an annular sealing plate 9 is arranged in the heat-insulating sealing cavity, and the inner surfac...

Embodiment 2

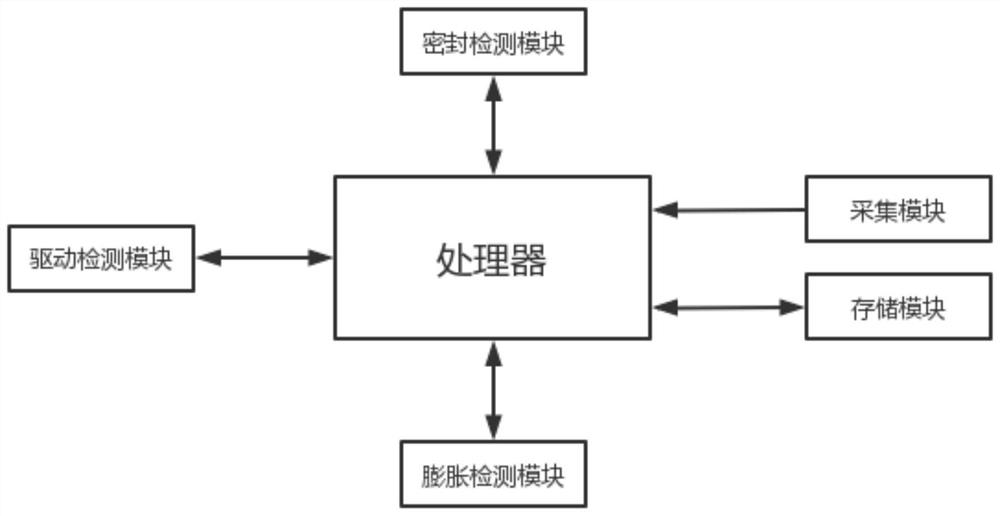

[0055] see image 3 As shown, a processor is provided on the outer surface of the casing 1, and the processor is connected to an acquisition module, an expansion detection module, a driving detection module, a sealing detection module and a storage module in communication.

[0056] The acquisition module includes a temperature sensor, an air flow sensor and a rotational speed sensor.

[0057] The sealing detection module is used to detect and analyze the heat conduction efficiency of the sealing gas: obtain the temperature performance values of the sealing gas inlet 14 and the sealing gas outlet 15 in real time and mark them as JWm and CWm respectively, and the temperature performance value JWm of the sealing gas inlet 14 is the sealing inlet The average value of the gas temperature value of the gas port and the temperature value of the inner wall of the sealed air inlet passage 12, the gas temperature value and the inner wall temperature value are directly collected by the ...

Embodiment 3

[0065] see Figure 4 As shown, a working method of a large-flow cryogenic gas bearing turboexpander comprises the following steps:

[0066] Step 1: Input gas at the bearing gas inlet 2 to control the rotation of the main shaft 5. When the main shaft 5 rotates, the expansion impeller 6 and the compression impeller 7 on both sides rotate synchronously. When the helium gas passes through the expansion impeller 6, the low-temperature helium gas flows in the channel that becomes larger and larger, and the pressure and velocity of the low-temperature helium gas decrease to reduce the internal energy of the gas and the temperature of the gas;

[0067] Step 2: While the main shaft 5 is rotating, gas is input into the sealing gas inlet 14. After heat exchange between the gas and the main shaft 5 is completed, the gas is discharged from the housing 1 through the sealing gas outlet channel 13 and the sealing gas outlet 15, and the gas in the sealing gas inlet channel 12 is supplied to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com