Electromagnetic actuator for variable valve lift camshaft and vehicle

An electromagnetic actuator, valve lift technology, applied in lift valves, machines/engines, non-mechanically actuated valves, etc., can solve the problems of large overall size, difficult layout, slow response time of electromagnetic actuators, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

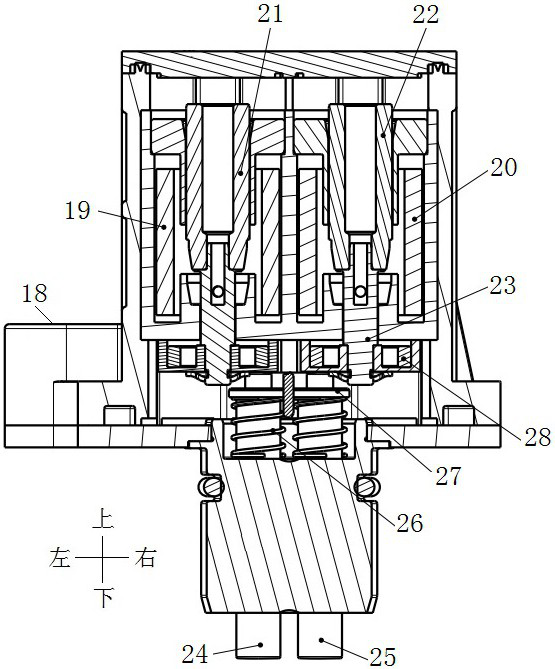

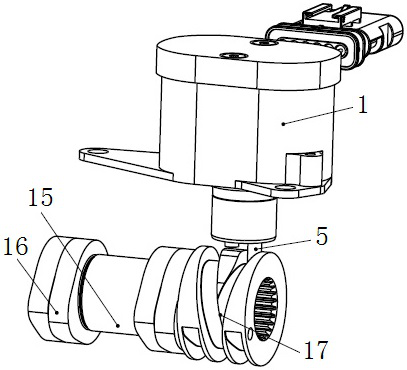

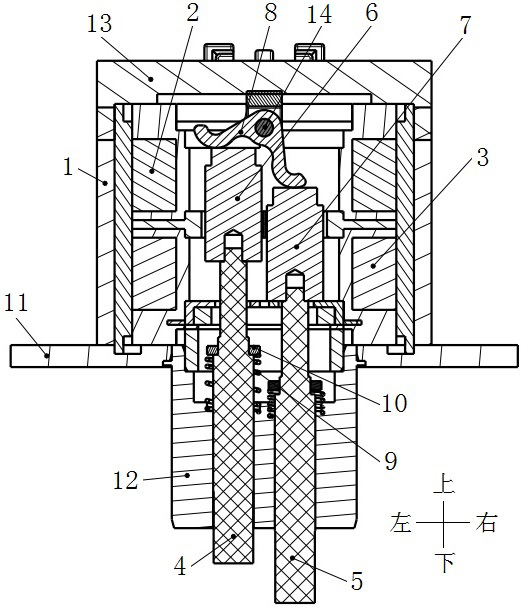

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] see figure 2 and image 3 , the shown electromagnetic actuator for the variable valve lift camshaft includes a housing 1, a solenoid arranged in the housing 1, a first push rod assembly 4 and a second push rod assembly arranged in parallel in the solenoid Push rod assembly 5 and reset assembly. The housing 1 includes a cylinder with an upper opening for installing a solenoid, a cover plate 13 for closing the upper opening of the cylinder, and a guide 12 connected below the cylinder.

[0023] The lower part of the housing 1 is provided with a mounting flange 11 extending radially outward, and the mounting flange 11 is provided with a mounting hole fixed to the vehicle body to provide an installation position for the assembly of the electromagnetic actuator on the vehicle body.

[0024] The solenoid includes a first solenoid 2 and a second solenoid 3 with co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com