Method and device for detecting state of filter screen of central range hood and electronic equipment

A range hood and filter technology, applied in the field of oil fume removal equipment, can solve the problems of poor timeliness and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

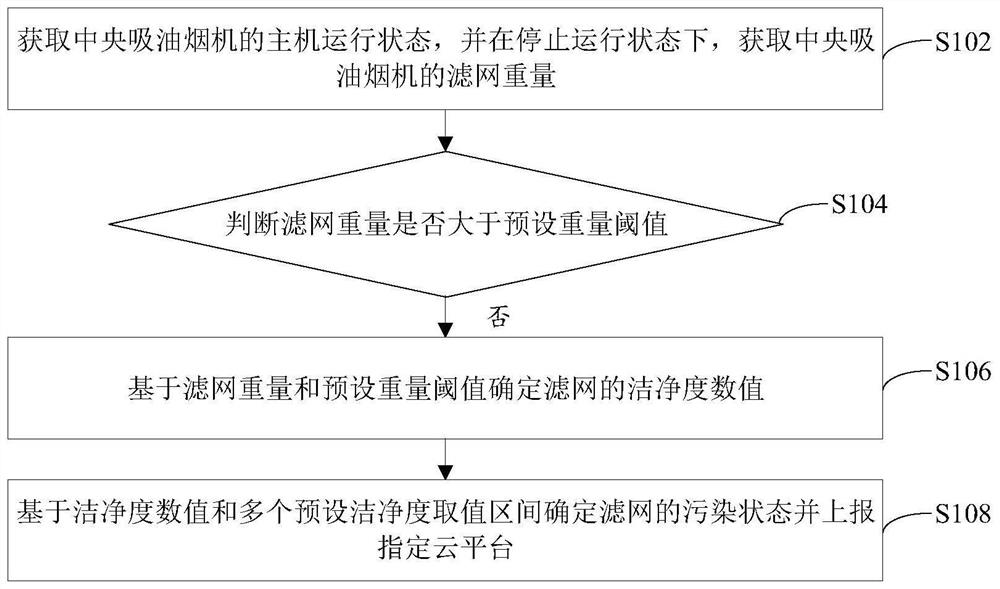

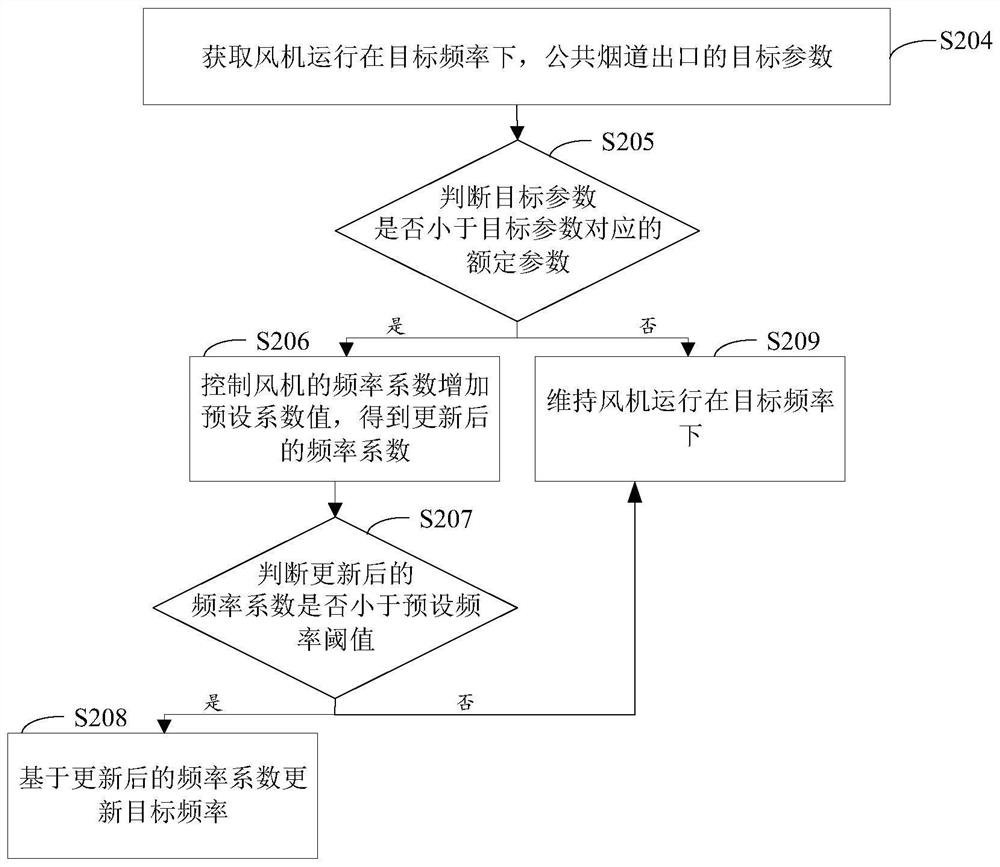

[0030] figure 1 A flow chart of a method for detecting the state of a filter screen of a central range hood provided by an embodiment of the present invention, as shown in figure 1 As shown, the method specifically includes the following steps:

[0031] Step S102, acquiring the running state of the host of the central range hood, and acquiring the weight of the filter screen of the central range hood in the stop running state.

[0032]The method for detecting the state of the filter screen of the central range hood provided by the embodiment of the present invention may be executed by a main controller in the central range hood, and the main controller is connected with a sensor for detecting the weight of the filter screen. The filter screen in the central range hood is set at the outlet of the flue under the support of the filter screen bracket. When the main unit of the central range hood is turned on, the fan runs, and under the action of the fan, the filter screen is sub...

Embodiment 2

[0080] The embodiment of the present invention also provides a central range hood filter state detection device, the central range hood filter state detection device is mainly used to implement the central range hood filter state detection method provided in the first embodiment above, The device for detecting the state of the filter screen of the central range hood provided by the embodiment of the present invention will be described in detail below.

[0081] Figure 5 It is a functional module diagram of a central range hood filter state detection device provided by an embodiment of the present invention, as shown in Figure 5 As shown, the device mainly includes: a first acquiring module 10, a first judging module 20, a first determining module 30, and a first reporting module 40, wherein:

[0082] The first acquiring module 10 is configured to acquire the operating state of the host of the central range hood, and acquire the weight of the filter screen of the central rang...

Embodiment 3

[0108] see Figure 6 , the embodiment of the present invention provides an electronic device, the electronic device includes: a processor 60, a memory 61, a bus 62 and a communication interface 63, the processor 60, the communication interface 63 and the memory 61 are connected through the bus 62; the processor 60 is used to execute executable modules, such as computer programs, stored in memory 61 .

[0109] Wherein, the memory 61 may include a high-speed random access memory (RAM, Random Access Memory), and may also include a non-volatile memory (non-volatile memory), such as at least one disk memory. The communication connection between the system network element and at least one other network element is realized through at least one communication interface 63 (which may be wired or wireless), and the Internet, wide area network, local network, metropolitan area network, etc. can be used.

[0110]The bus 62 can be an ISA bus, a PCI bus or an EISA bus, etc. The bus can be ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap