Tunnel lining thickness detection device

A technology of thickness detection and lining, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of insufficient accuracy of capacitance testing instruments, inconvenient operation and use, and complicated testing equipment, and achieve strong rigidity, easy maintenance and replacement, and shrinkage volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

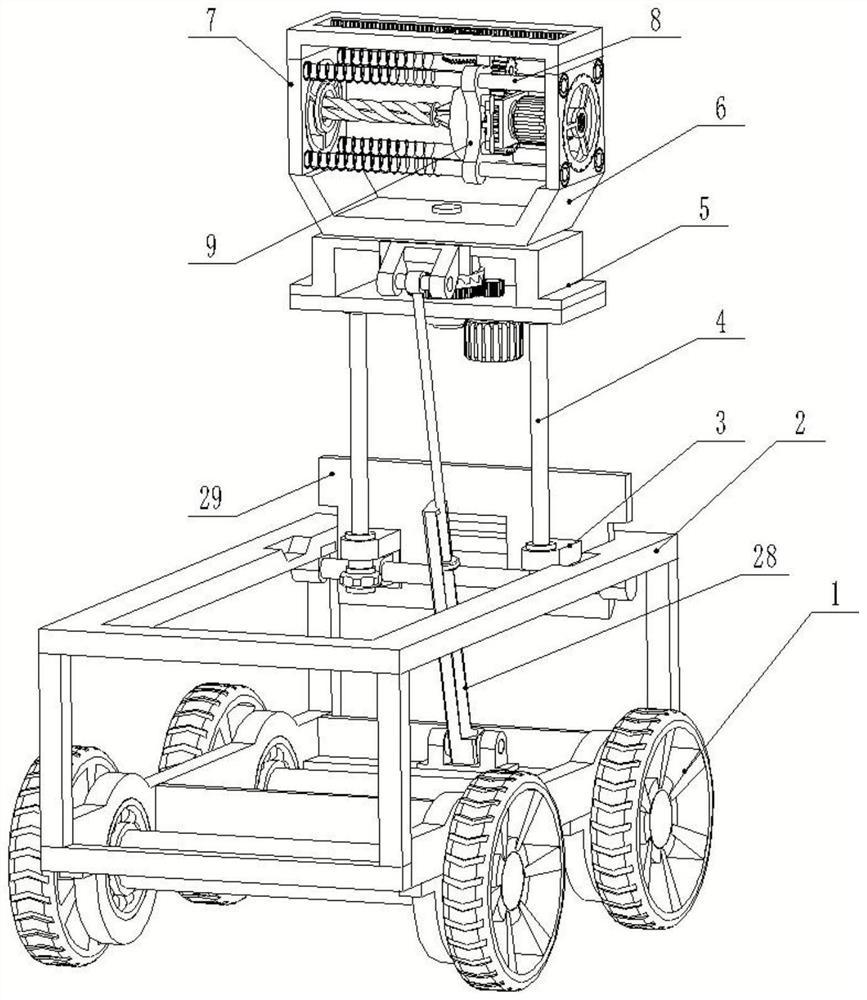

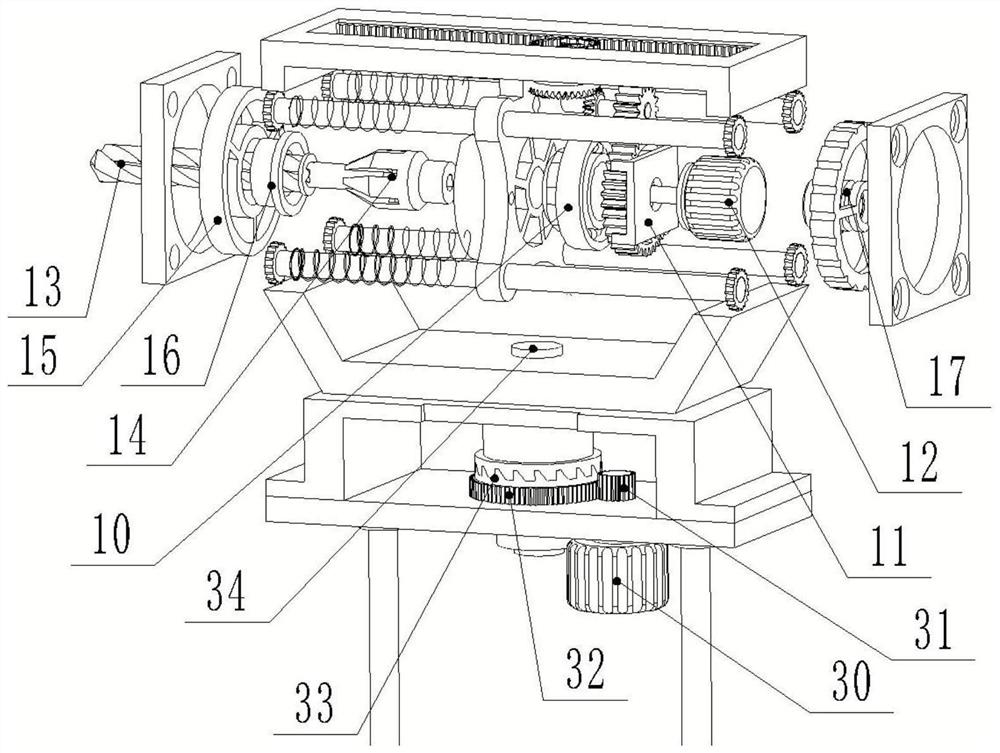

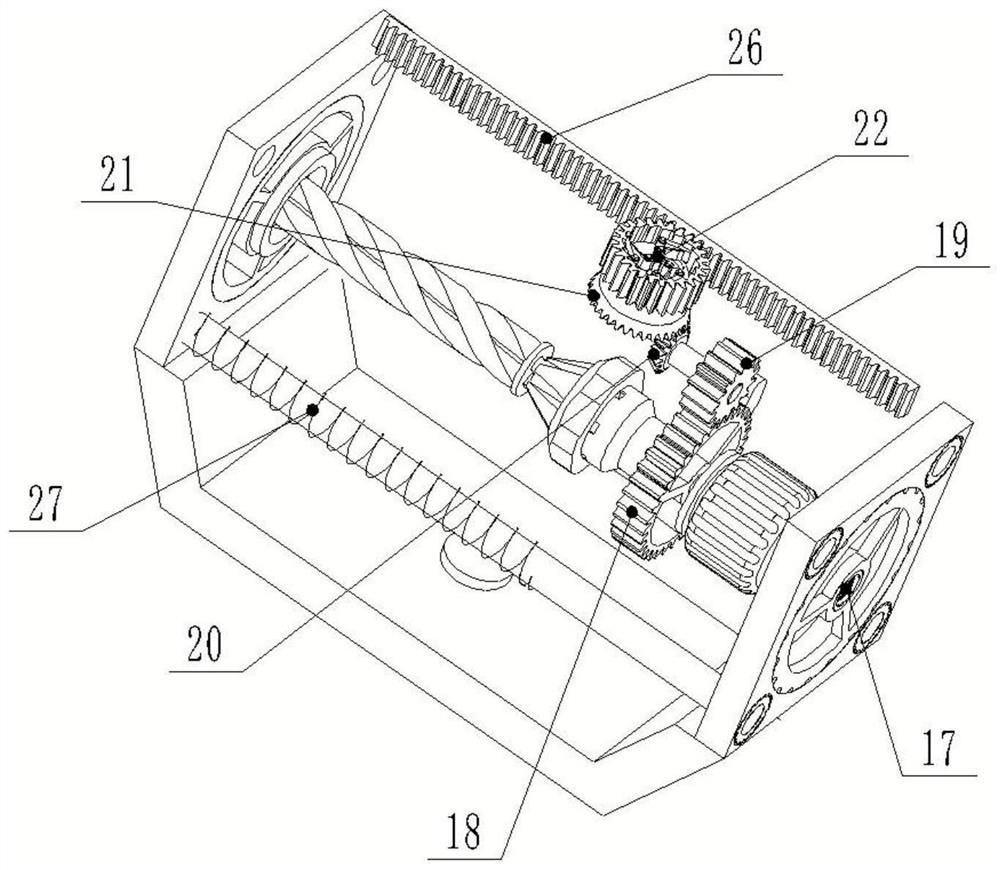

[0026] Such as Figure 1~4 As shown, a tunnel lining thickness detection device includes a vehicle frame 2 with traveling wheels 1, a sliding seat 3 is fixed on the vehicle frame 2, and a lifting shaft 4 is slid inside the sliding seat 3, and the top end of the lifting shaft 4 is fixed There is a support base 5, and the support base 5 is connected with a punching and detection integrated block through a rotating mechanism; the punching and detection integrated block includes a chute plate 6 that is rotatably connected with the support base 5, and a chute plate 6 is fixed on the upper end of the chute plate 6. The frame 7 is provided with several slide bars 8 horizontally in the frame 7, and a center disc 9 is slidably connected to the slide bar 8, and a shaft coupling 10 is fixed in the center disc 9, and a fixed plate 11 is connected to one side of the center disc 9. A drilling motor 12 is fixed on the fixed plate 11, and the rotating shaft of the drilling motor 12 is connect...

Embodiment 2

[0039] Such as Figure 5 with Image 6 As shown, the difference between Embodiment 2 and Embodiment 1 is that a slide rail 35 is rotatably connected to the vehicle frame 2 of the detection device, and a slide block 38 is slidably provided on the slide rail 35, and a slide block 38 is provided below the slide block 38. Sliding motor 36 is fixed, and sliding gear 37 is fixed on the rotating shaft of sliding motor 36, and sliding gear 37 is engaged with the longitudinal rack on the slide rail 35; An acoustic wave detector 40 is slidably connected to the upper part; a torque sensor is also arranged on the auger rod 13 .

[0040] The course of work of embodiment 2:

[0041] First slide rail 35 is raised to vertical shape, then starts acoustic wave detector 40, and acoustic wave detector 40 carries out 360 ° all-round scanning tunnel inner wall on universal ball 39, detects whether there is the place of hollow drum, after finding, Drill holes and measure thickness according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com