Method for evaluating heated cigarette formula based on material heated mass change information

A technology of quality change and formula, applied in the field of tobacco, can solve problems such as strong subjectivity and high work intensity, and achieve the effect of objective method, small sample usage, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Select 5 grams each of 1 standard formula sample and 7 heated cigarette formula samples, pass through a 100-mesh sieve respectively, and pass through a constant temperature and humidity environment of (22±1)°C and relative humidity of (60±2)% for 48 Hour.

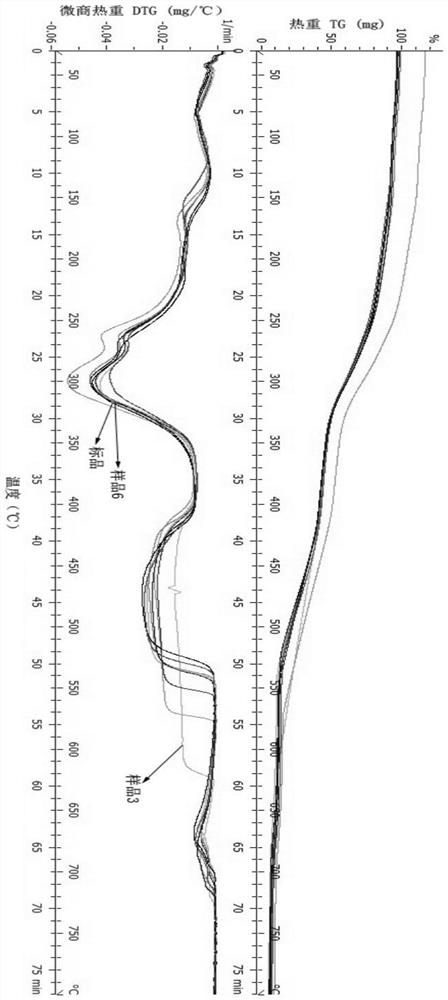

[0030] 2. Before sample analysis, set the thermogravimetric analyzer to keep at 900°C for 10 minutes, so that the impurities in the furnace body can be removed, and the empty crucible is used as a reference. Weigh (5.00±0.05) mg sample and place it in a thermogravimetric platinum crucible. The heating program is as follows: initial temperature 30°C, heating rate 10°C / min, end temperature 350°C, and test at 50mL / min air flow. The balance sensitivity is not lower than 0.1μg, and the curve resolution is not lower than 50 million resolution points.

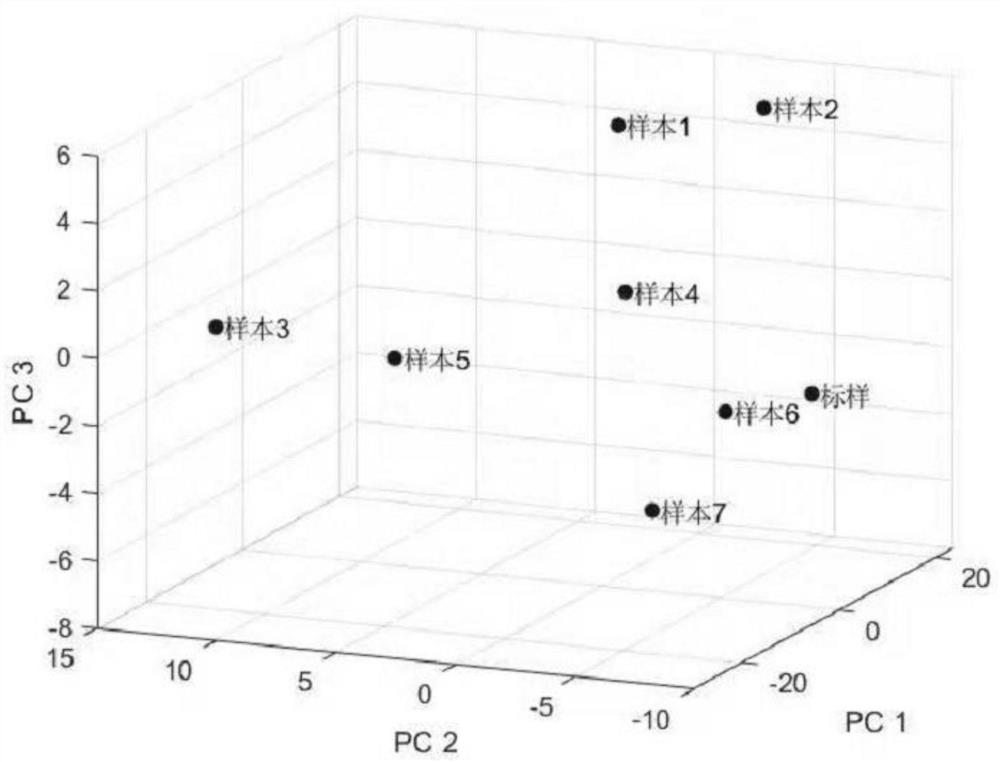

[0031] 3. Obtain the 350°C thermogravimetric curves of the heated cigarette formula sample (sample) and the standard formula sample (standard product), and obtain the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com