Cylindrical rolling body fragmentation contact stress detection method, terminal and computer readable storage medium

A technology of contact stress and detection method, applied in the field of bearing design, can solve the problem of not considering the stress concentration at both ends of the cylindrical rolling body, and achieve the effect of verifying the rationality and the reliable verification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solutions and advantages of the application clearer, the technical solutions in the embodiments of the application will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the application. It should be understood that the accompanying drawings in the application are only It serves the purpose of illustration and description, and is not used to limit the protection scope of the present application.

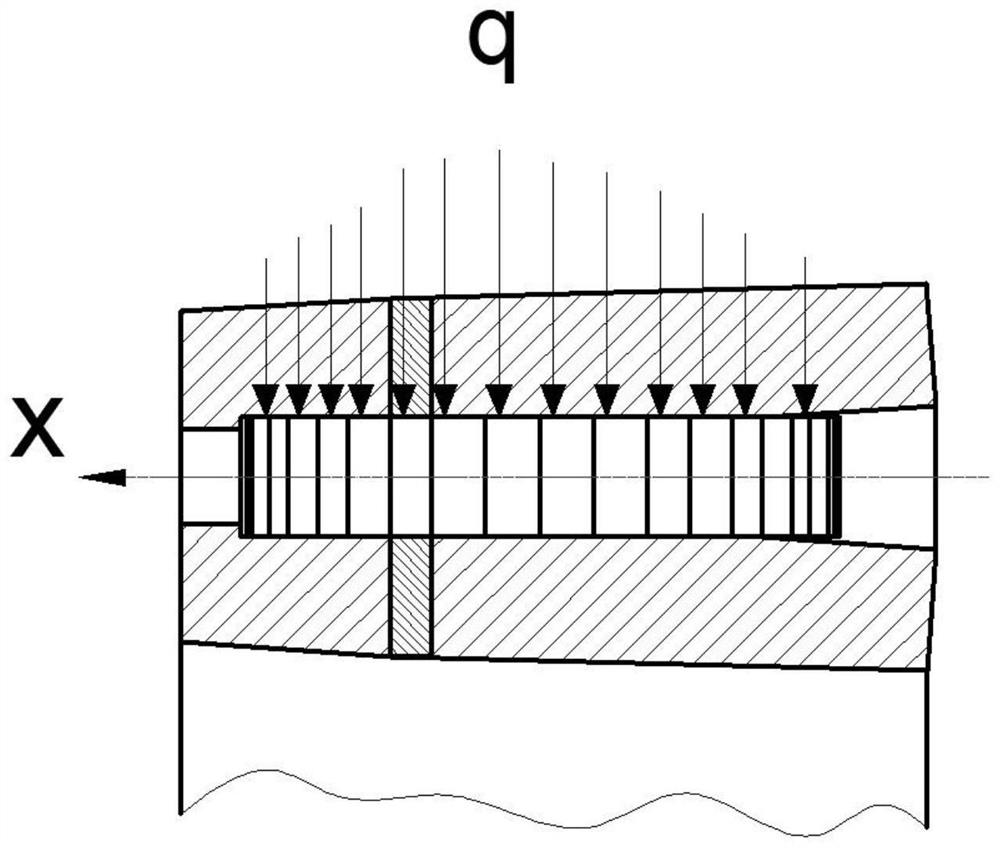

[0034] The embodiment of the present application provides a method for detecting contact stress of a cylindrical rolling element in slices, including the following steps:

[0035] Step S1, according to the distribution of the load on the cylindrical rolling element, the load-bearing part of the cylindrical rolling element is divided into several slices along the axial direction of the cylindrical rolling element, wherein the denser the load, the thinner the slice;

[0036] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com