Semi-supervised industrial defect detection method and system based on feature comparison

A defect detection and feature comparison technology, applied in the field of deep learning and computer vision, can solve problems such as confusion, unavoidable semantics, and limited precision, and achieve the effects of improving precision, avoiding confusion, and strong detection capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

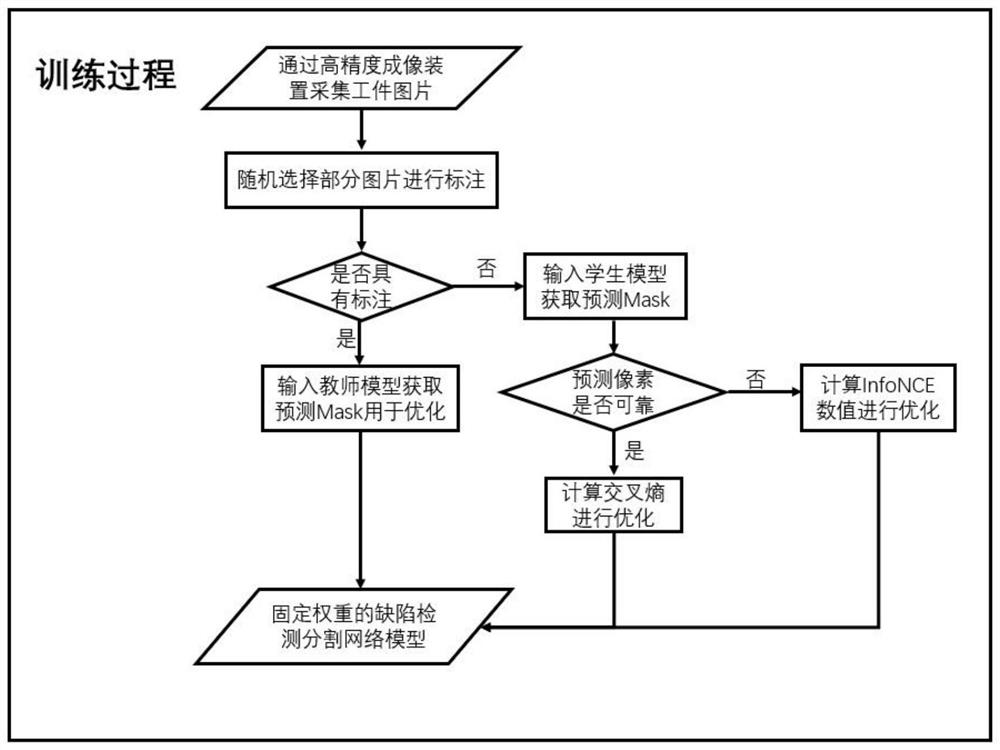

[0080] According to the present invention provides a semi-supervised industrial defect detection method based on feature comparison, such as Figure 1- Figure 3 shown, including:

[0081] Step S1: Collect the pictures of the products to be tested and label the pictures randomly;

[0082] Step S2: Classify the products to be tested, divided into labeled input and unlabeled input;

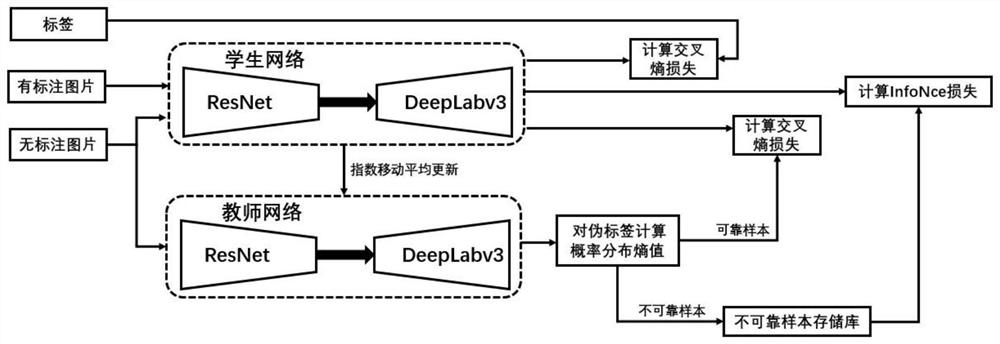

[0083] Step S3: For labeled input, train the student network with pictures and corresponding labels;

[0084] For unlabeled input, the input into the teacher network produces the corresponding pseudo-labels and representations;

[0085] Step S4: Filter for pseudo-labels to distinguish between reliable pixels and unreliable pixels;

[0086] Step S5: Supervise the feeding of reliable pixels into the student network, and for the unreliable pixels, the characteristic optimization of the student network based on contrast learning is based on their feature encoding information.

[0087] Specifically, in the ste...

Embodiment 2

[0112] Example 2 is a preferred example of Example 1, to illustrate the present invention more specifically.

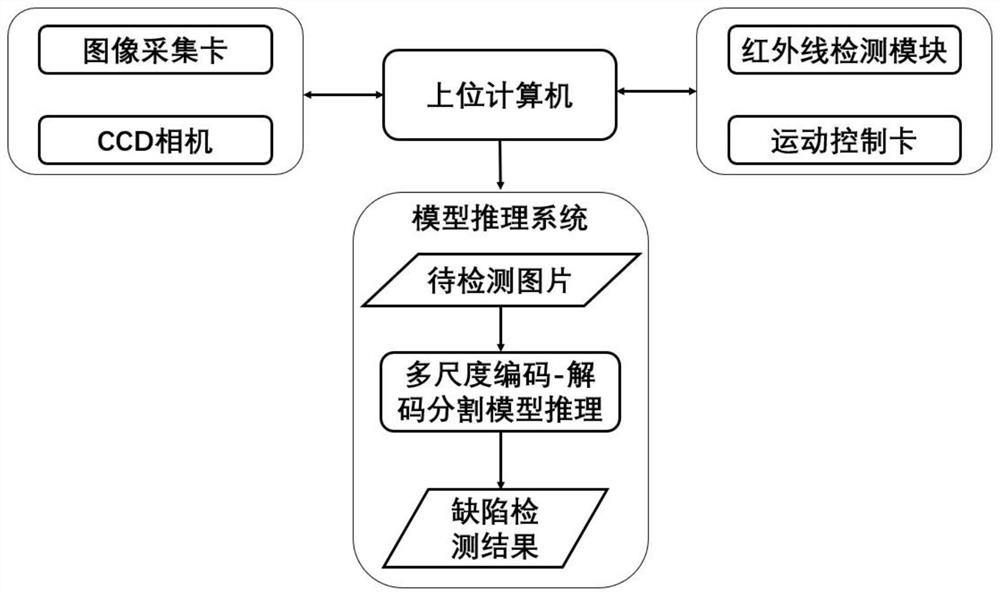

[0113] Those skilled in the art may provide a semi-supervised industrial defect detection method based on feature comparison provided by the present invention, to be understood as a specific embodiment of a semi-supervised industrial defect detection system based on feature comparison, i.e., the semi-supervised industrial defect detection system based on feature comparison may be implemented by performing the step flow of the semi-supervised industrial defect detection method based on feature comparison.

[0114] According to the present invention provides a semi-supervised industrial defect detection system based on feature comparison, comprising:

[0115] Module M1: Collect the pictures of the products to be tested, and randomly label the pictures;

[0116] Module M2: Classify the products to be tested, divided into labeled input and unlabeled input;

[0117] Module M3:...

Embodiment 3

[0146] Example 3 is a preferred example of Example 1, to illustrate the present invention more specifically.

[0147] 1. A semi-supervised industrial defect detection system and method based on feature comparison, including:

[0148] Step A: Collect the pictures of the products to be tested, and mark the pixels of some pictures to form an input sample with some supervision information.

[0149] Step B: According to whether the product under test has a picture, the input sample is divided into "labeled input" and "unlabeled input".

[0150] Step C: For "Label Input", directly use these pictures and corresponding labels to train the student network.

[0151] Step D: For "Unlabeled Input", enter it into the teacher network, generating the corresponding pseudo-labels and representations.

[0152] Step E: Using the entropy value, the pseudo-labels are filtered at the pixel level to distinguish between high-confidence and low-confidence pseudo-labels.

[0153] Step F: For high-confidence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com