Construction tool and construction method for rapid in-place and replacement of large transformer

A construction method and technology for transformers, which are applied in inductance/transformer/magnet manufacturing, switchgear, electrical components, etc., can solve the problems of long construction time, high-altitude work, and low installation accuracy for large transformers, and improve equipment installation efficiency. , save the work, easy to operate and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

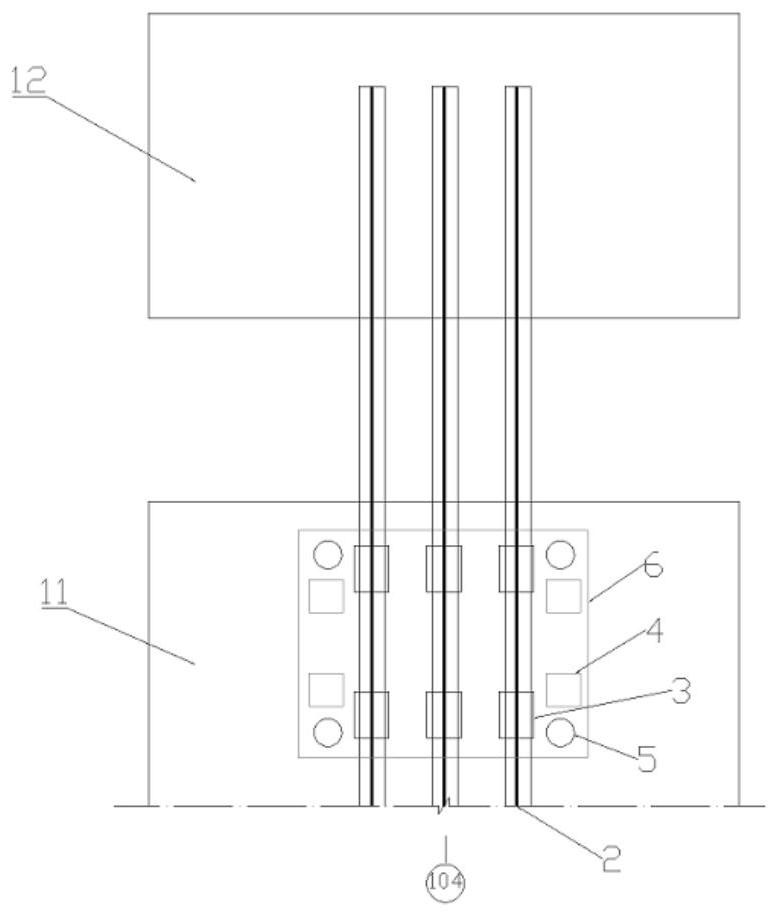

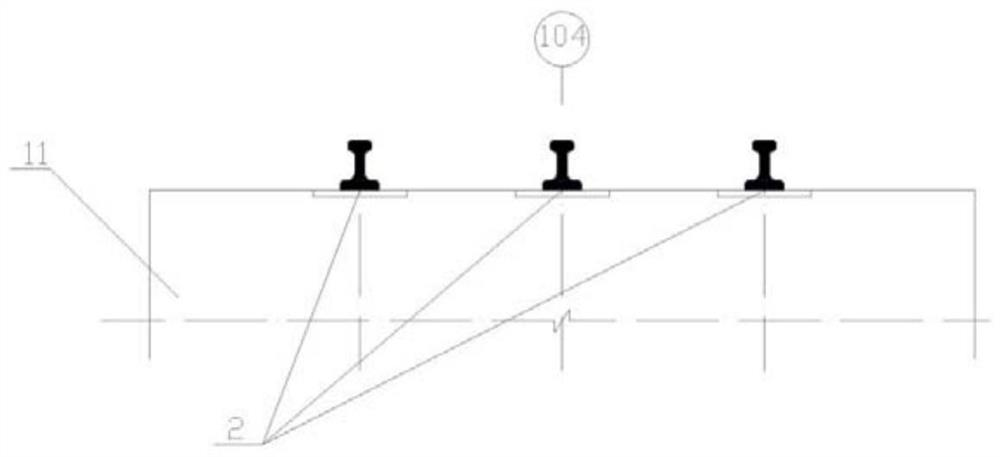

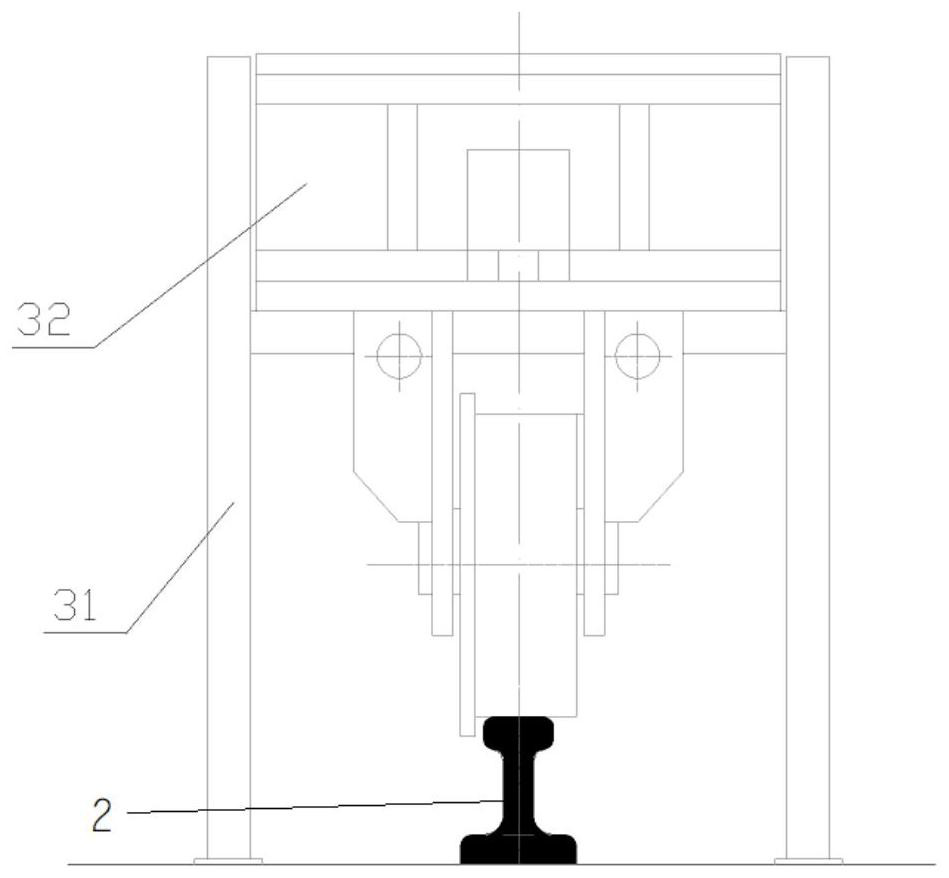

[0047] Such as figure 1 As shown, a construction tool for large-scale transformer installation includes a permanent track 2, a rolling device 3, a transformer positioning tool 4 and a transformer lifting tool 5; the track 2 is fixed on the construction floor and extends from the transformer assembly station 11 to the transformer installation station 12. Such as figure 2 As shown, track 2 is three parallel QU70 track steels. The transformer positioning tool 4 and the transformer lifting tool 5 are detachable. Such as image 3 As shown, the rolling bearing 32 of the rolling device is connected above the track 2 . Two rolling bearings 32 and rolling bearing positioning tooling 31 are arranged on any one track. The rolling bearing positioning tooling 31 includes angle steel and support plates. The selected angle steel specification is L45*5mm, and the support plate is a 5mm thick steel plate. Such as Figure 4 As shown, the transformer positioning tool 4 includes H-shaped...

Embodiment 2

[0057] The construction of a large-scale transformer replacement using the construction tooling in Implementation 1 includes the following steps:

[0058] Step S1, using the track 2 to hoist the transformer 6 from the transformer installation station 12 to the assembly station 11;

[0059] Step S2, using the transformer lifting tooling 5 to lift the transformer and the rolling support off the track 2 as a whole;

[0060] Step S3, the transformer body 6 is disengaged from the rolling bearing 32;

[0061] Step S4, hoisting and replacing the transformer body;

[0062] Step S5, the replaced transformer is positioned and leveled using the transformer positioning tool 4;

[0063] Step S6, the replaced transformer body is connected to the rolling bearing 32;

[0064] Step S7, use the transformer lifting tooling 5 to lower the replaced transformer and rolling bearing as a whole and place it on the track 2;

[0065] Step S8, hoisting the replaced transformer to the transformer inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com