Replaceable basket for bucket of machine

A bucket and machine technology, applied in the field of maintaining buckets used in machines, can solve the problems of heavy buckets and easy wear and tear of skeleton frames.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

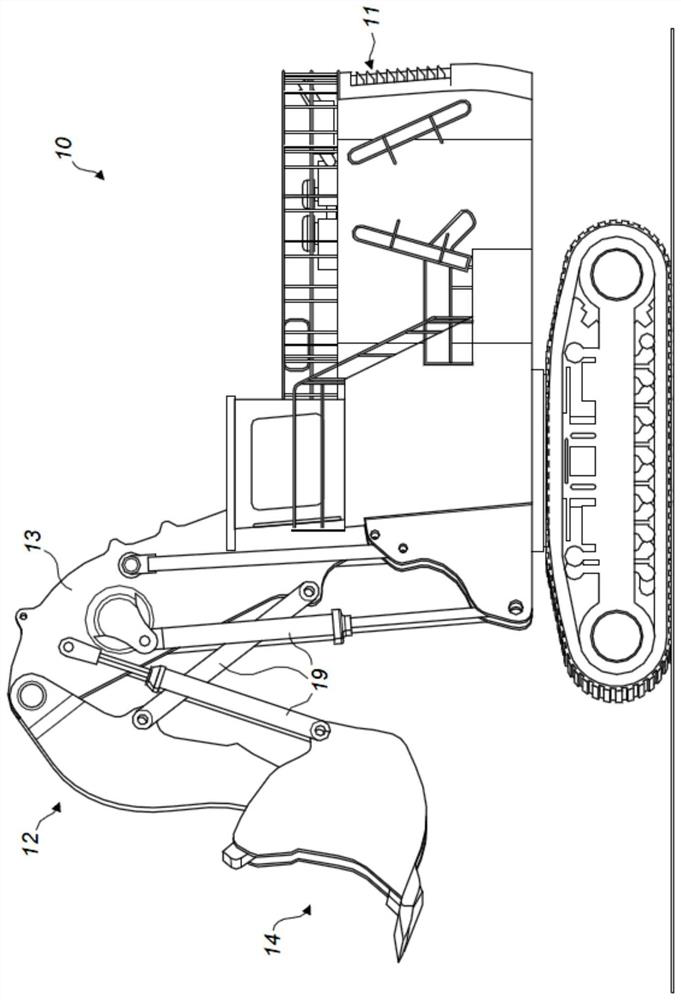

[0015] figure 1 A machine 10 including a bucket 14 of the present invention is shown. Machine 10 may include a main body 11 and a work tool 12 attached to main body 11 . Work tool 12 may include arm assembly 13 , which may include a boom and rod mounted to body 11 as shown, and bucket 14 attached to arm assembly 13 as shown. The work tool 12, and in particular the arm arrangement 13, may be controlled by at least one actuator 19 to move the bucket 14 and perform work. In the illustrated embodiment, machine 10 comprises a hydraulic mining shovel, although machine 10 may be of any other type that includes bucket 14, such as an excavator, backhoe loader, wheel loader, track loader, shovel loader machines or other material handling machines.

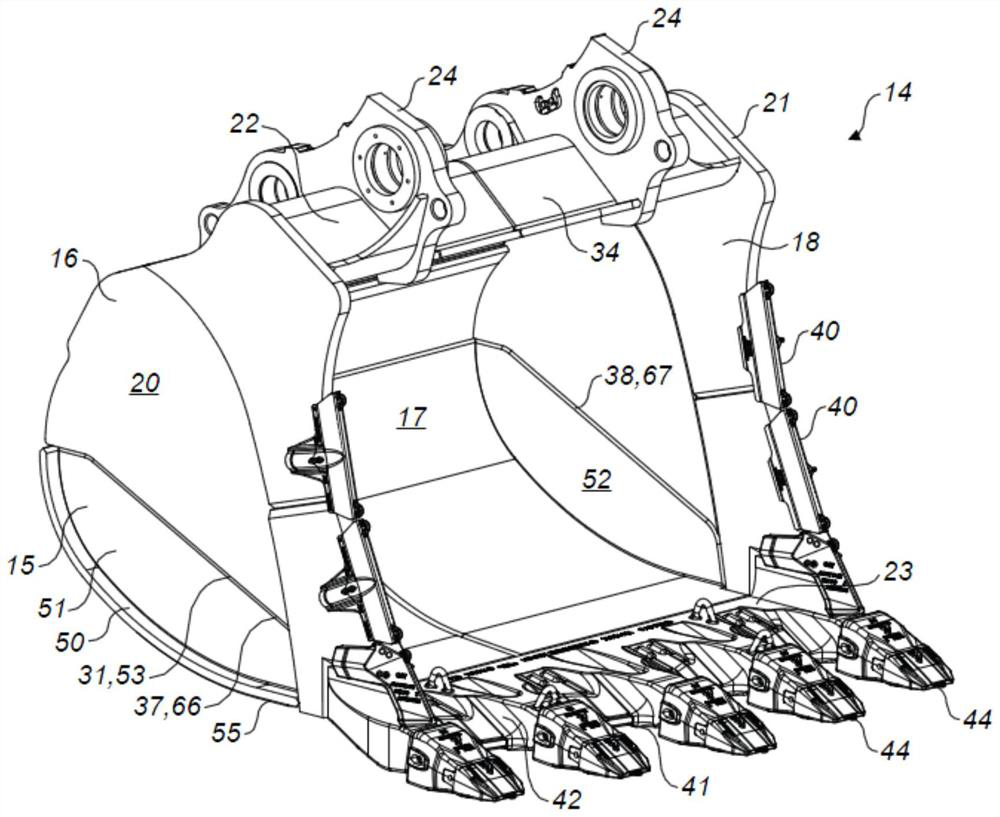

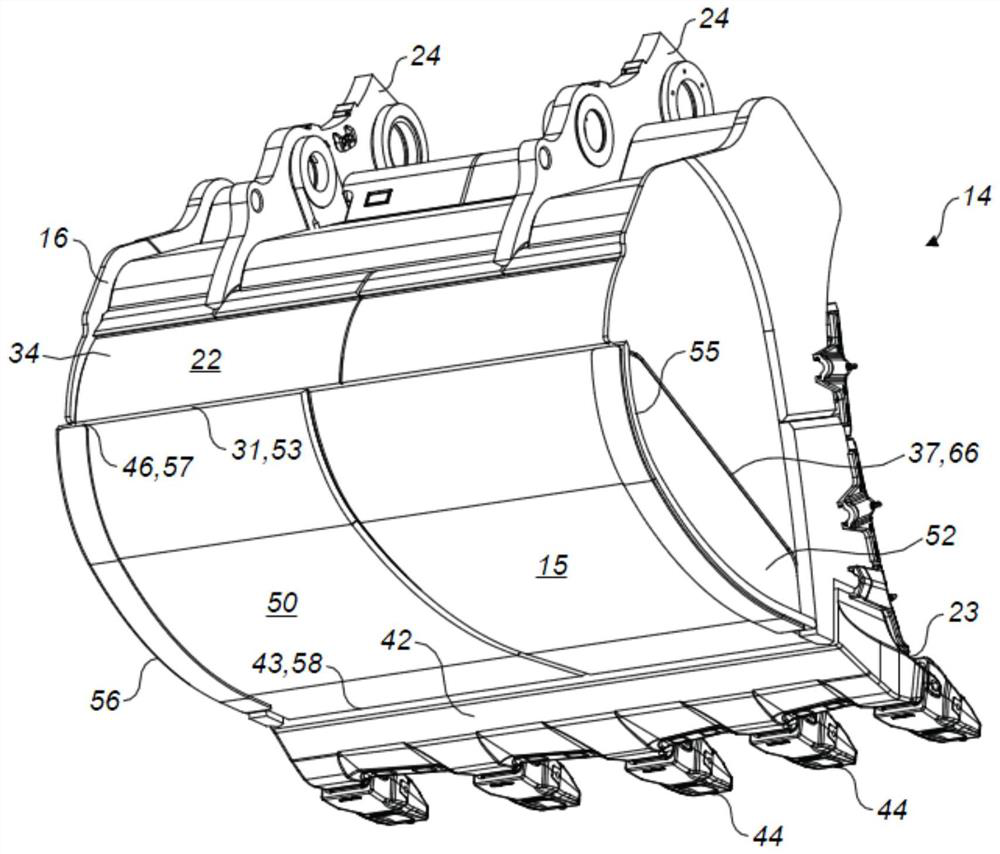

[0016] Figure 2 to Figure 7 Bucket 14 is shown in greater detail. Bucket 14 includes a replaceable basket 15 mounted to a main body 16 . Basket 15 is configured to experience most of the wear and tear of bucket 14 during its operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com