Welding device for positive pole of cylindrical battery

A cylindrical battery and welding device technology, applied in welding equipment, battery pack components, laser welding equipment, etc., can solve the problem of low welding efficiency of positive pole column, and achieve the effect of improving welding efficiency and reducing use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

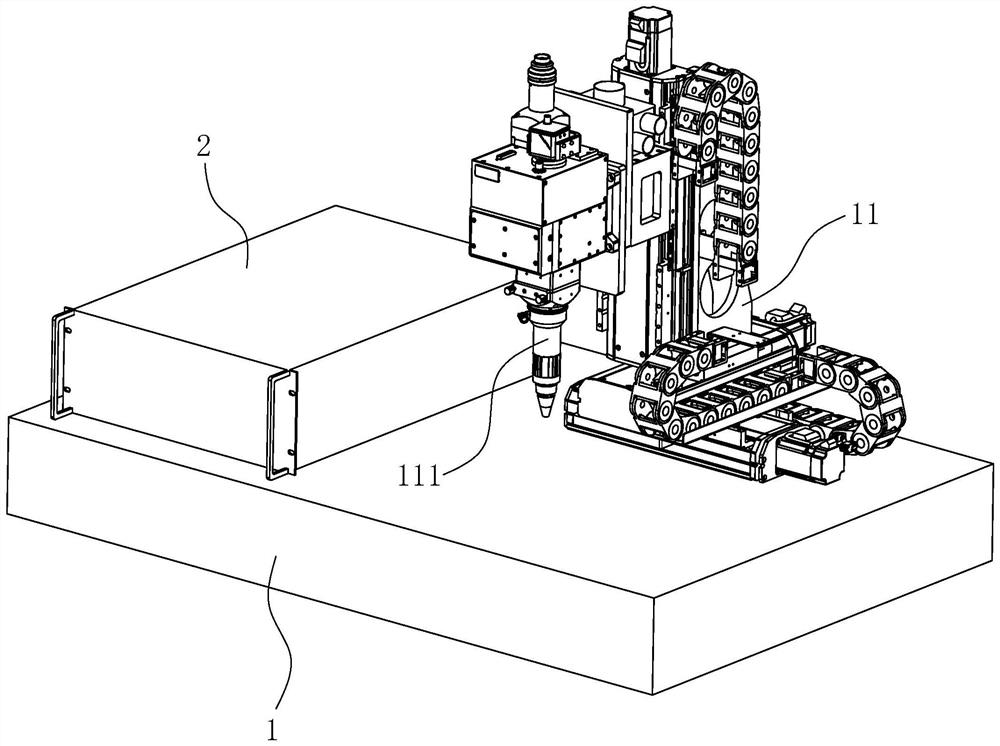

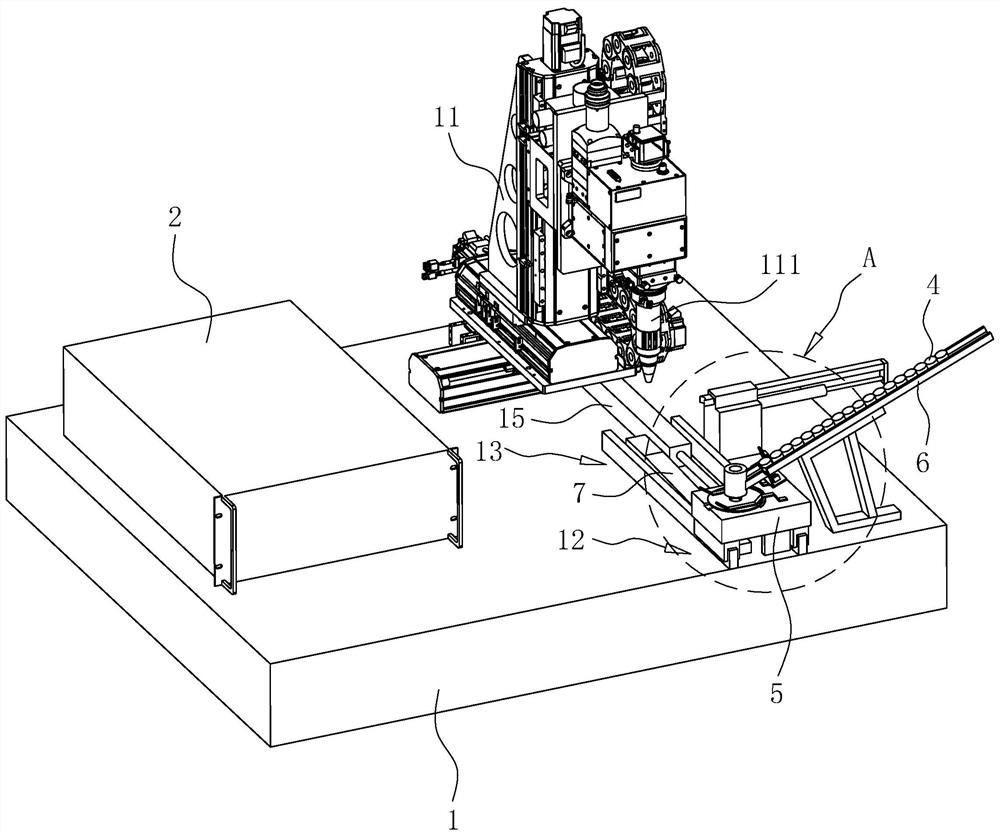

[0045] refer to image 3 A welding device for a cylindrical battery positive pole includes a base 1 and a laser generator 2 . The base 1 is provided with a bracket 11, and the bracket 11 is provided with a laser welding head 111, and the laser welding head 111 is connected with the bracket 11 through a screw nut structure, so that the laser welding head 111 can be adjusted up and down. The bracket 11 is connected to the base 1 through two sets of orthogonally arranged screw nut structures, so as to facilitate the movement of the bracket 11 in the horizontal plane. In this embodiment, the laser generator 2 is a fiber laser to improve the operation stability of the welding device.

[0046] refer to image 3 and Figure 4 , the base 1 is provided with a loading station 12 and a welding station 13; the welding station 13 is located below the laser welding head 111. The upper surface of the base 1 is fixed with a slide rail 14 by screws, one end of the slide rail 14 is located ...

Embodiment 2

[0059] The difference between this embodiment and embodiment 1 is:

[0060] refer to Figure 7 and Figure 8 , the base 1 is rotatably connected with a rotating disk 16 through a bearing, and the axial direction of the rotating shaft of the rotating disk 16 is arranged along the up-down direction. The number of mounting bases 5 may be one, and the number of mounting bases 5 may be two or even more; in this embodiment, the number of mounting bases 5 is six. All the mounting seats 5 are uniformly and distributed sequentially along the circumferential direction of the rotating disk 16 , and all the mounting seats 5 are welded and fixed to the rotating disk 16 . In this embodiment, the position for the operator to install the collector plate 3 is the clamping station 17 , and the position for the base 1 to weld the pusher seat 9 is the pusher station 18 . The feeding station 12, the clamping station 17, the welding station 13, and the pushing station 18 are arranged at interval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com