Laser cutting device

A laser cutting and lens technology, which is applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as poor adaptability, high production cost, and redundant overall structure size, so as to reduce cost and complexity and facilitate processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

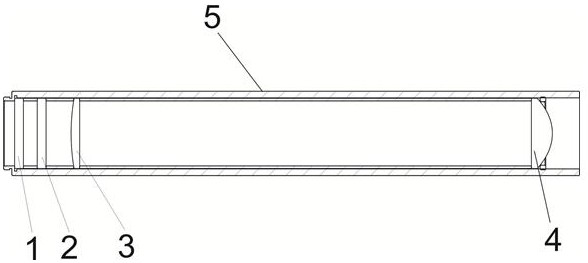

[0043] Such as figure 1 As shown, this embodiment is a laser cutting device, including a housing 5, a quarter wave plate 1 and a lens, the quarter wave plate 1 and the lens are installed in the housing, and the lens includes diffraction cones arranged in sequence Lens 2, first lens 3 and second lens 4, wherein the diffractive axicon 2 is closer to the quarter-wave plate 1, the effective distance of the first lens 3 is 150mm, and the size is 25.4mm, and the effective focal length of the second lens 4 The diameter is 20mm, and the size is 25.4mm. The first lens 3 and the second lens 4 form a bi-telecentric system. The two meet the confocal condition and form a beam reducer.

[0044] In this embodiment, the quarter-wave plate 1 is composed of a substrate glass, a protective glass, and a liquid crystal molecular film layer, wherein the substrate glass is located in the middle, and the three are pasted together by optical glue. The quarter-wave plate In 1, the thickness of the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com