Device for reducing liquor loss of liquor tank

A liquor and tank technology, applied in the field of liquor storage, can solve the problems of inability to promote aging of liquor, inability to transfer heat directly, and inability to extract liquor well, so as to promote maturation, improve heat exchange efficiency, increase The effect of the heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

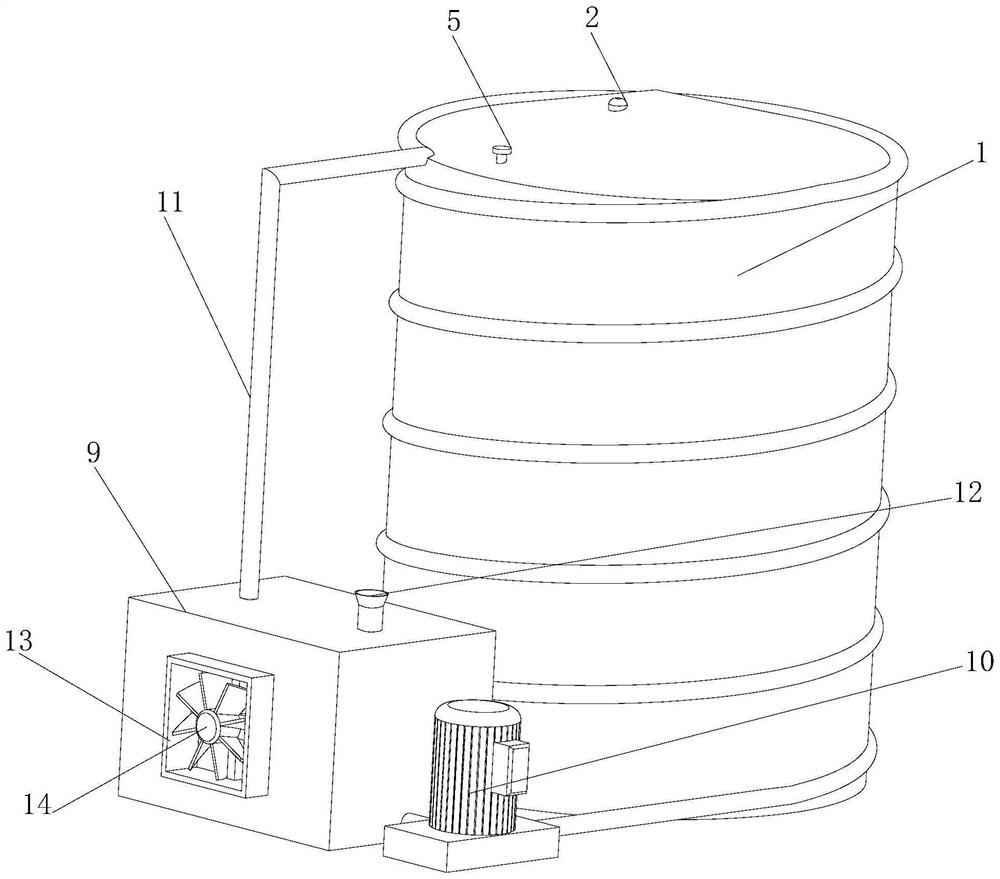

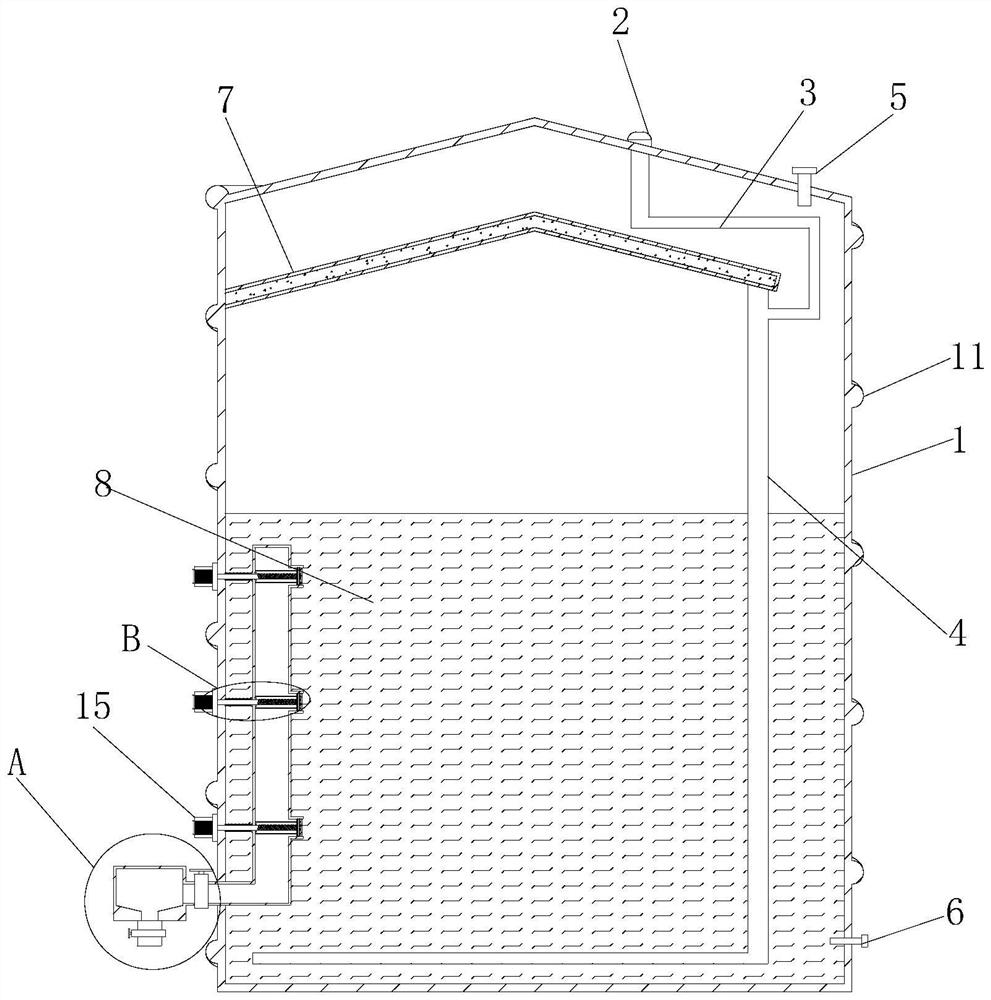

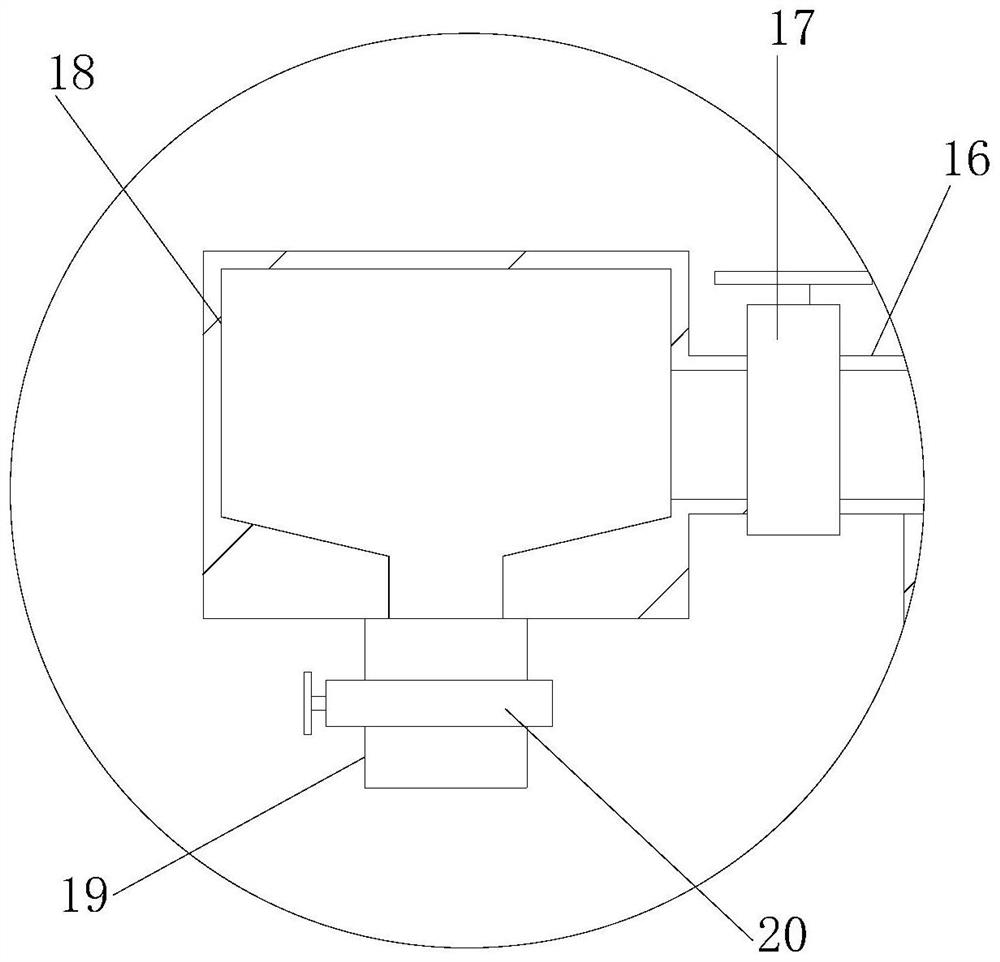

[0030] see Figure 1-Figure 7 , the present invention provides a device for reducing wine damage to liquor tanks, which includes a tank body 1 and a fixed box 9, the fixed box 9 is located on one side of the tank body 1, an upper head 2 is installed on the top of the tank body 1, and the inside of the tank body 1 is sealed. Filled with wine liquid 8, the interior of the tank body 1 is provided with a heat conduction mechanism that guides the excess heat at the top of the tank body 1 into the wine liquid 8, and the interior of the tank body 1 is provided with a loss reduction mechanism for reducing the loss of the wine liquid 8, and the interior of the fixed box 9 is provided with There is a temperature regulating mechanism for adjusting the internal temperature of the tank body 1, and the inside of the tank body 1 is provided with an extraction mechanism that can extract different levels of wine liquid 8; One end of the conductive tape 3 is fixedly connected to one side of the...

Embodiment 2

[0033] refer to figure 1 , Image 6, the temperature adjustment mechanism includes a circulating water pump 10, a flow pipe 11, a liquid storage tank 28 and a filling port 12, the circulating water pump 10 is fixedly installed on one side of the fixed box 9, the liquid storage tank 28 is fixedly installed inside the fixed box 9, and the filling port 12 is fixedly connected to the top of the liquid storage tank 28, the filling port 12 is located at the top of the fixed tank 9, the connection end of the circulating water pump 10 communicates with the liquid storage tank 28, and the flow pipe 11 is fixedly connected to the output end of the circulating water pump 10 and the interior of the liquid storage tank 28 Between them, the flow pipe 11 is fixedly connected to the side wall of the tank body 1, and the flow pipe 11 is evenly distributed on the side wall of the tank body 1 in a spiral shape. The temperature adjustment mechanism also includes a first temperature sensor 5, a se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap