Method for detecting phosphorus element in phosphating film of phosphating galvanized steel sheet

A technology of galvanized steel sheet and phosphorus element, applied in the field of detection, can solve the problems of many types of chemicals, large environmental impact, complicated steps, etc., and achieve the effects of rapid detection, high sensitivity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

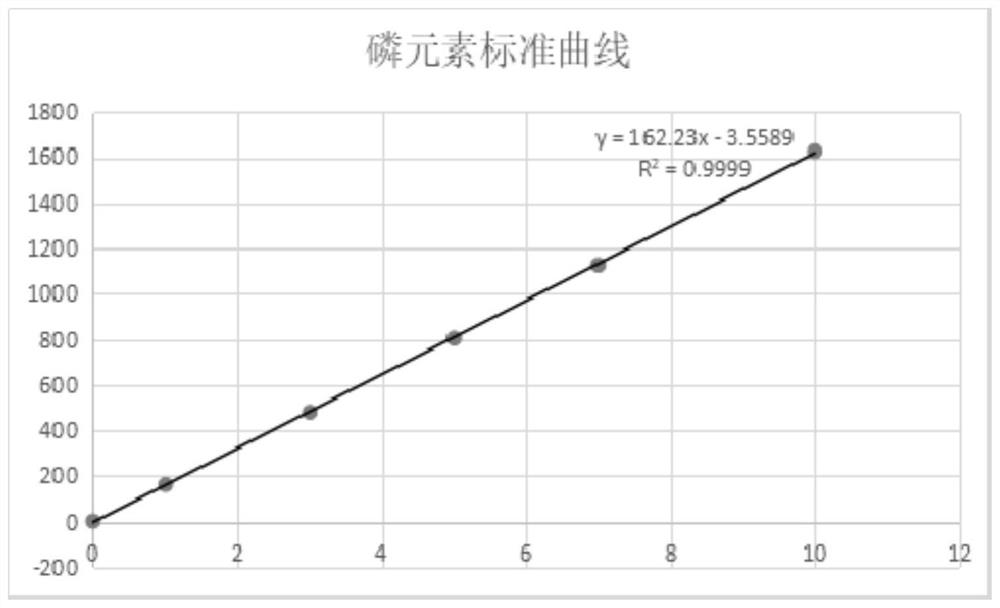

Image

Examples

Embodiment 1

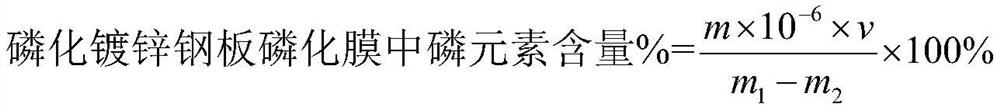

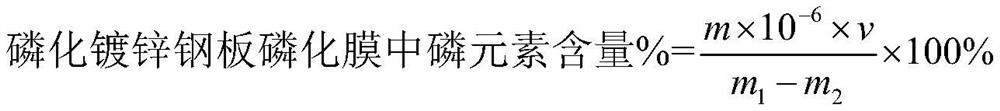

[0038] A method for detecting phosphorus in phosphating coatings on phosphating galvanized steel sheets, comprising the following process steps:

[0039] 1.1 Sample preparation

[0040] Take the DC06E+Z galvanized steel plate and cut it into a square with a side length of 2cm. The surface is cleaned with alcohol, and weighed after drying. The weight is m 1 Put the weighed sample into a 100mL beaker, add 5mL of chromium trioxide solution (1%, prepared with distilled water), immerse the sample in the solution completely, count for 15min, take the sample out of the solution, and rinse the surface of the sample with distilled water , combine the flushing solution into the chromium trioxide solution used for immersion. Dry the sample with a hair dryer, weigh the sample after drying, and the weight is m 2 . Transfer the solution in the beaker to a 100mL volumetric flask, make up to volume with distilled water, and mix well. This solution is the solution to be tested.

[0041] 1...

Embodiment 2

[0054] 2.1 Sample preparation

[0055]Take the DC01E+Z galvanized steel plate and cut it into a square with a side length of 2cm. Clean the surface with alcohol and weigh it after drying. The weight is m 1 Put the weighed sample into a 100mL beaker, add 5mL of chromium trioxide solution (1%, prepared with distilled water), immerse the sample in the solution completely, count for 15min, take the sample out of the solution, and rinse the surface of the sample with distilled water , combine the flushing solution into the chromium trioxide solution used for immersion. Dry the sample with a hair dryer, weigh the sample after drying, and the weight is m 2 . Transfer the solution in the beaker to a 100mL volumetric flask, make up to volume with distilled water, and mix well. This solution is the solution to be tested.

[0056] 2.2 Sample detection

[0057] The solution to be tested was detected by an inductively coupled plasma atomic emission spectrometer.

[0058] First use an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com