Thermally conductive silicone grease composition

A heat-conducting silicone grease and composition technology, which is applied in the field of heat-conducting materials, can solve problems such as the inability to meet the requirements of large deformation and low thermal resistance, the drying of the colloid, the increase in the hardness of the colloid, the decrease in elongation, and the decrease in surface viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

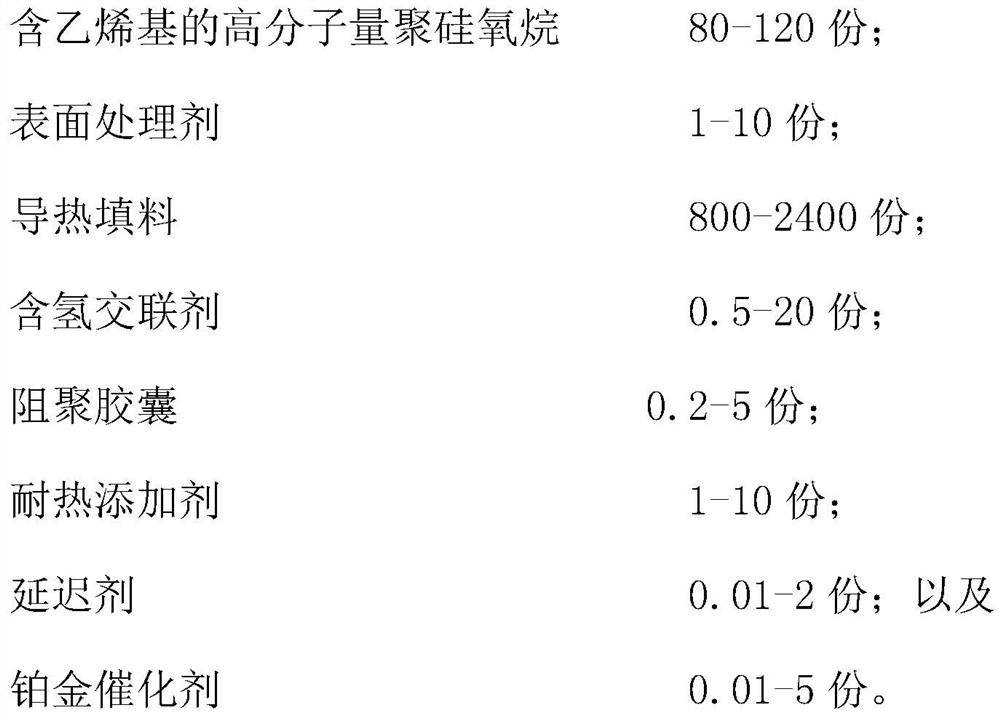

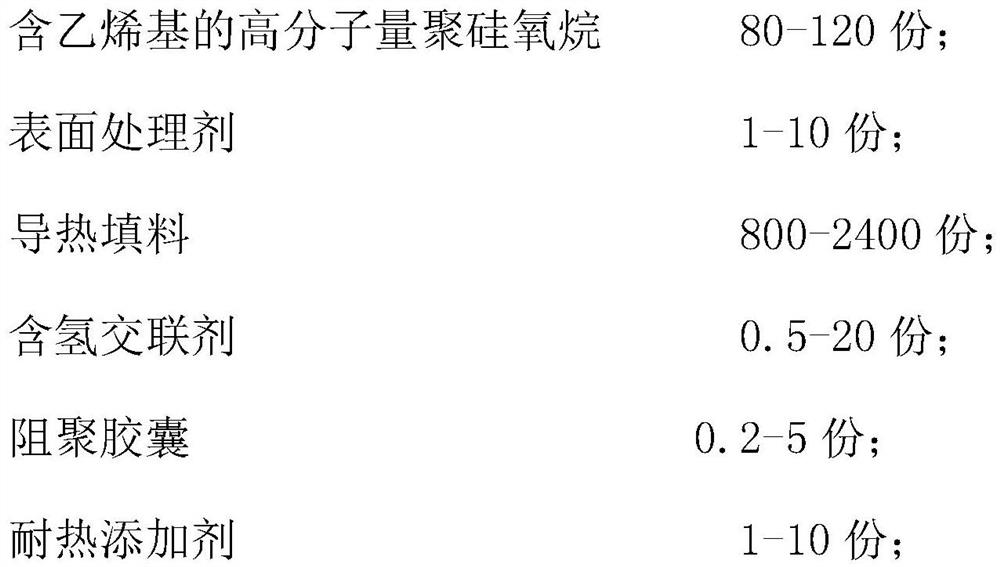

Method used

Image

Examples

Embodiment 1

[0038]The 100g viscosity of 500cs end vinyl polysiloxane, 3g viscosity of 100cs of single-ended trimethoxy polysiloxane added to the 2L kneading machine, stirred at room temperature for 5 minutes, and then added in batches of 1000g of spherical alumina with an average particle size of 20 μm, 250g of spherical alumina with an average particle size of 5 μm, and 100g of spherical alumina with an average particle size of 0.5 μm, and then added 5 g of iron oxide. After mixing at room temperature for 1 hour, vacuum mixing at high temperature of 150 °C for 2 hours, after mixing to room temperature, add 10g of hydrogen mass percentage content of 0.1%, viscosity of 100cs hydrogen-containing silicone oil, add 0.5g of polymerization capsule, 0.05g of 1-acetylenyl-1-cyclohexanol, add 5000ppm of Karstedt catalyst with platinum content of 5000ppm 0.1g, mix at room temperature for 30 minutes, vulcanize at 25 °C on the flat plate vulcanizing machine for 12 hours, and obtain 120mm* 120mm * 2mm she...

Embodiment 2

[0040] The 100g viscosity of 100cs end vinyl polysiloxane, 3g viscosity of 100cs of single-ended trimethoxy polysiloxane added to the 2L kneading machine, stirred at room temperature for 5 minutes, and then added 1000g of spherical alumina with an average particle size of 20 μm, 250g of spherical alumina with an average particle size of 5 μm and 100g of spherical alumina with an average particle size of 0.5 μm, and then added 5 g of iron oxide. After mixing at room temperature for 1 hour, vacuum mixing at high temperature of 150 °C for 2 hours, after mixing to room temperature, add 12g of hydrogen mass percentage content of 0.1%, viscosity of 100cs hydrogen-containing silicone oil, add 0.8g of polymerization resistance capsules, 0.05g of 1-acetylene-1-cyclohexanol, add 5000ppm of Karstedt catalyst with platinum content of 5000ppm 0.1g, mix at room temperature for 30 minutes, vulcanize at 25 °C on the flat plate vulcanizer for 12 hours, to obtain 120mm* 120mm * 2mm sheet, after tes...

Embodiment 3

[0042]The 100g viscosity of 500cs end vinyl polysiloxane, 3g viscosity of 15cs of single-ended trimethoxy polysiloxane added to the 2L kneading machine, stirred at room temperature for 5 minutes, and then added 1000g of spherical aluminum with an average particle size of 20 μm, spherical alumina with an average particle size of 5 μm at 180g and spherical alumina with an average particle size of 0.5 μm at 150g, and then added 5g of iron oxide. After mixing at room temperature for 1 hour, vacuum mixing at high temperature of 150 °C for 2 hours, after mixing to room temperature, add 10g of hydrogen mass content of 0.1%, viscosity of 100cs hydrogen-containing silicone oil, add 0.6g of polymerization capsules, 0.05g1-acetylene-1-cyclohexanol, add 5000ppm of Karstedt catalyst with platinum content of 5000ppm 0.1g, mix at room temperature for 30 minutes, vulcanize at 25 °C on the plate vulcanizer for 12 hours, and obtain 120mm** 120mm * 2mm sheet, after testing the hardness, elongation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com