Al-Mg-Li-Zr-Er alloy

An al-mg-li-zr-er, alloy technology, applied in the field of metal alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

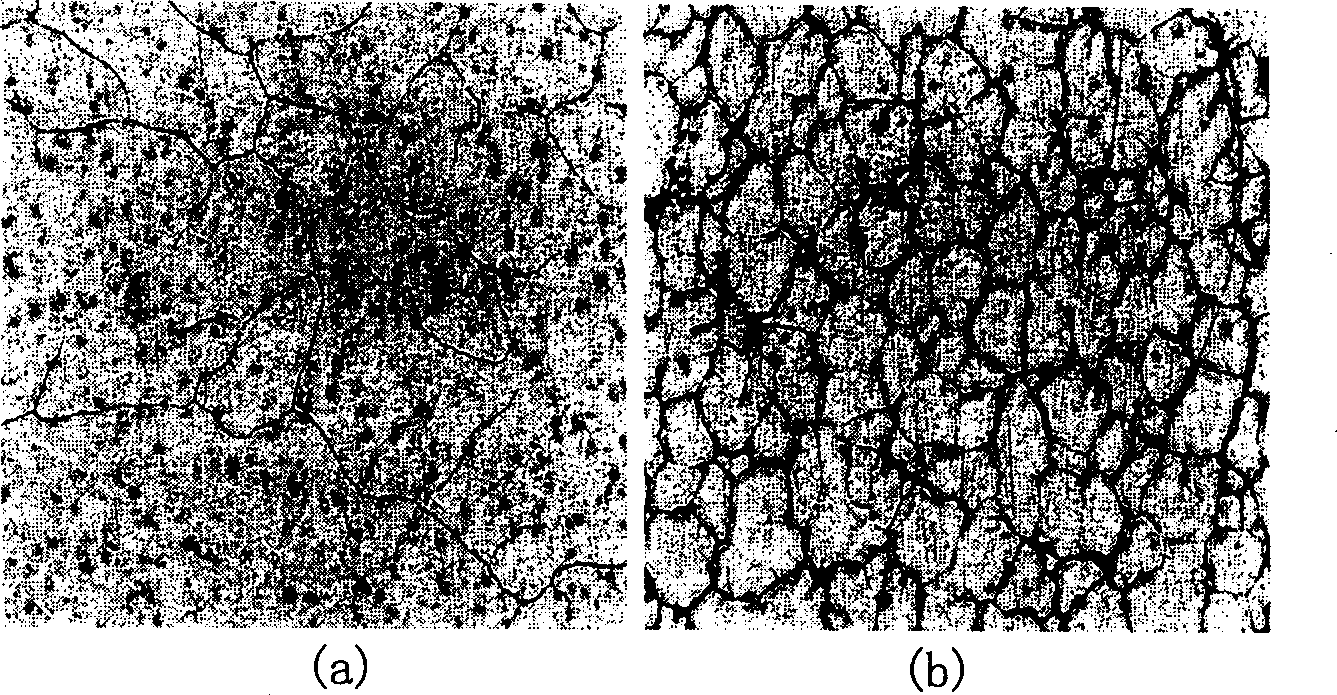

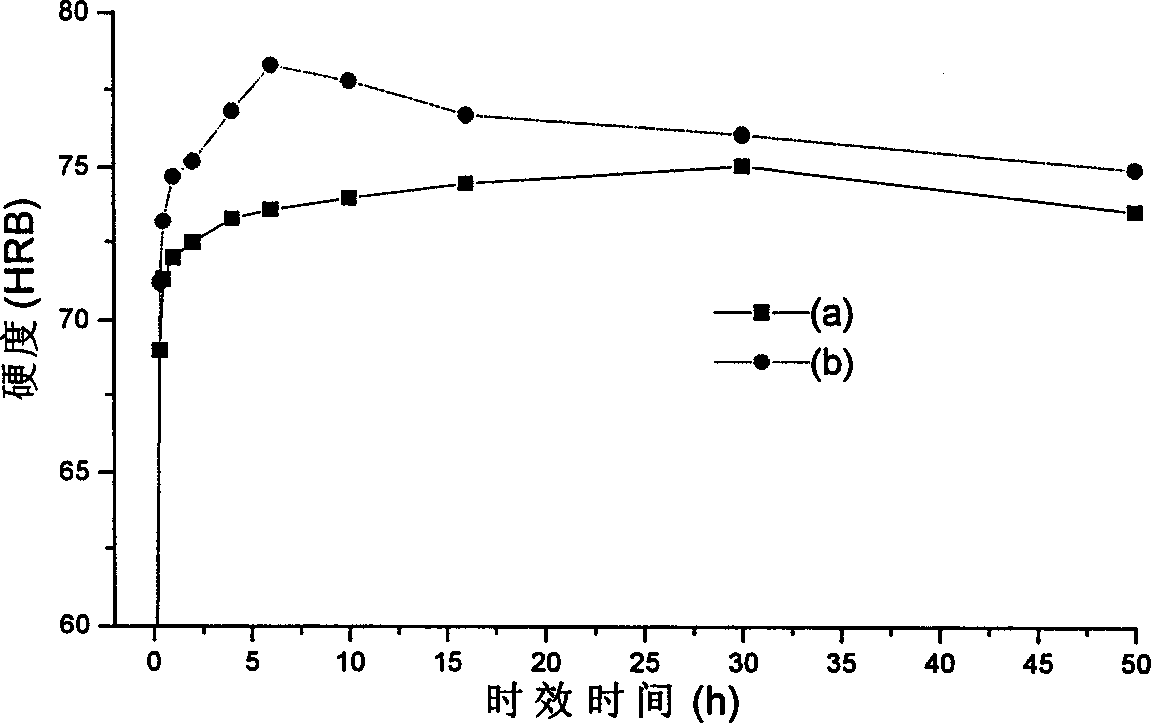

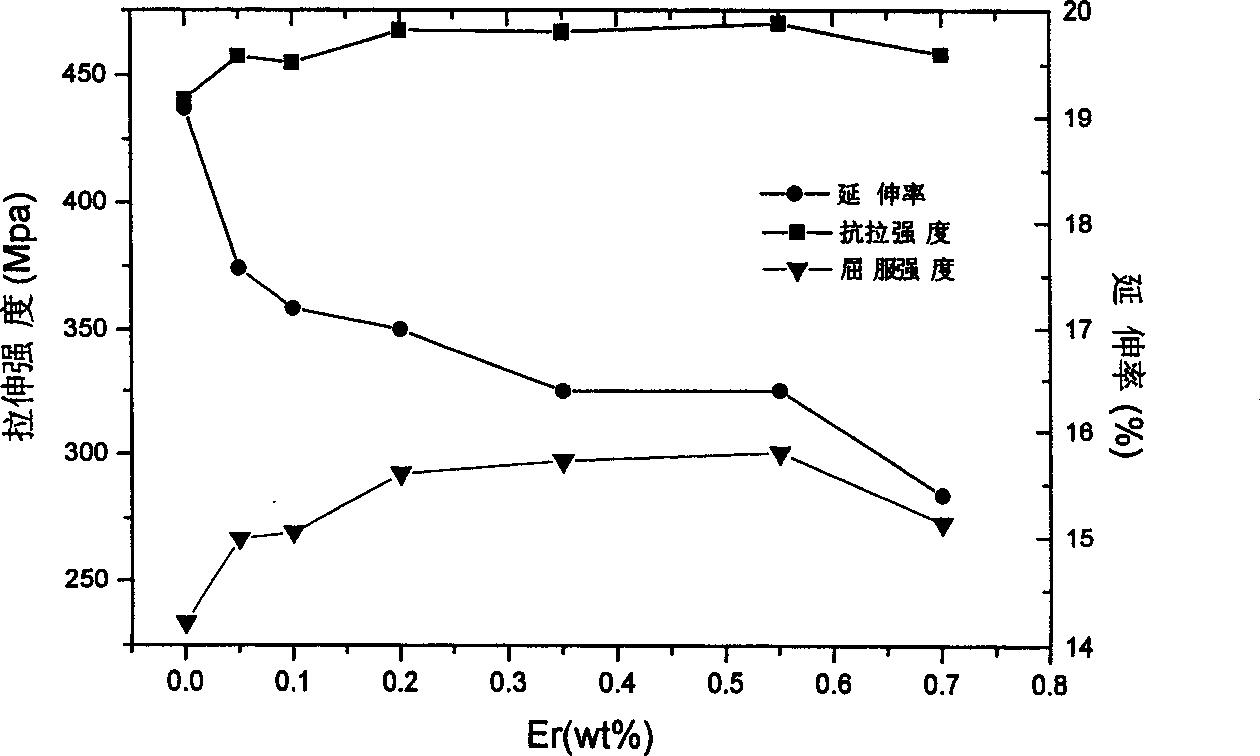

[0012] Example 1: The Al-Mg-Li-Zr-0.05Er alloy is prepared by the ingot metallurgy method. The specific composition is shown in Table 1. The raw materials used are high-purity Al with a purity of 99.99%, high-purity Mg with a purity of 99.99%, and a purity of 99.99%. 99.99% high-purity Li and master alloys Al-3.6wt% Zr, Al-6.2wt% Er are batched according to the bulk density of the casting mold 10kg. Put 8818 grams of high-purity aluminum, 361 grams of Al-Zr master alloy and 81 grams of Al-6.2Er master alloy into Al 2 o 3 Crucible, and put it in a ZGG-0.025 vacuum induction furnace. After the vacuum degree is higher than 0.3Pa, turn on the power to raise the temperature of the material, until the solution temperature rises to 760 ° C, turn off the power, and keep the vacuum degassing. When the temperature of the solution drops to 710°C and the vacuum degree is above 0.3 Pa, argon gas of 200 mmHg is introduced, 540 grams of Mg and 200 grams of Li are added, and Li is wrapped wi...

example 2

[0013] Example 2: Al-Mg-Li-Zr-0.1Er alloy is prepared by ingot metallurgy, the specific composition is shown in Table 1, the raw materials used are high-purity Al with a purity of 99.99%, high-purity Mg with a purity of 99.99%, and a purity of 99.99%. 99.99% high-purity Li and master alloys Al-3.6wt% Zr, Al-6.2wt% Er are batched according to the bulk density of the casting mold 10kg. Put 8737 grams of high-purity aluminum, 361 grams of Al-Zr master alloy and 162 grams of Al-6.2Er master alloy into Al 2 o 3 Crucible, and put it in a ZGG-0.025 vacuum induction furnace. After the vacuum degree is higher than 0.3Pa, turn on the power to raise the temperature of the material, until the solution temperature rises to 760 ° C, turn off the power, and keep the vacuum degassing. When the temperature of the solution drops to 710°C and the vacuum degree is above 0.3 Pa, argon gas of 200 mmHg is introduced, 540 grams of Mg and 200 grams of Li are added, and Li is wrapped with aluminum foi...

example 3

[0014] Example 3: Al-Mg-Li-Zr-0.2Er alloy is prepared by ingot metallurgy method. The specific composition is shown in Table 1. The raw materials used are high-purity Al with a purity of 99.99%, high-purity Mg with a purity of 99.99%, and a purity of 99.99%. 99.99% high-purity Li and master alloys Al-3.6wt% Zr, Al-6.2wt% Er are batched according to the bulk density of the casting mold 10kg. Put 8575 grams of high-purity aluminum, 361 grams of Al-Zr master alloy and 324 grams of Al-6.2Er master alloy into Al 2 o 3 Crucible, and put it in a ZGG-0.025 vacuum induction furnace. After the vacuum degree is higher than 0.3Pa, turn on the power to raise the temperature of the material, until the solution temperature rises to 760 ° C, turn off the power, and keep the vacuum degassing. When the temperature of the solution drops to 710°C and the vacuum degree is above 0.3 Pa, argon gas of 200 mmHg is introduced, 540 grams of Mg and 200 grams of Li are added, and Li is wrapped with alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com