Polyethylene gas pipe

A technology of polyethylene and gas pipes, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems of gas leakage, gas pipes are easy to be cut through, pipeline detection and positioning are inconvenient, etc., and achieve the effect of improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

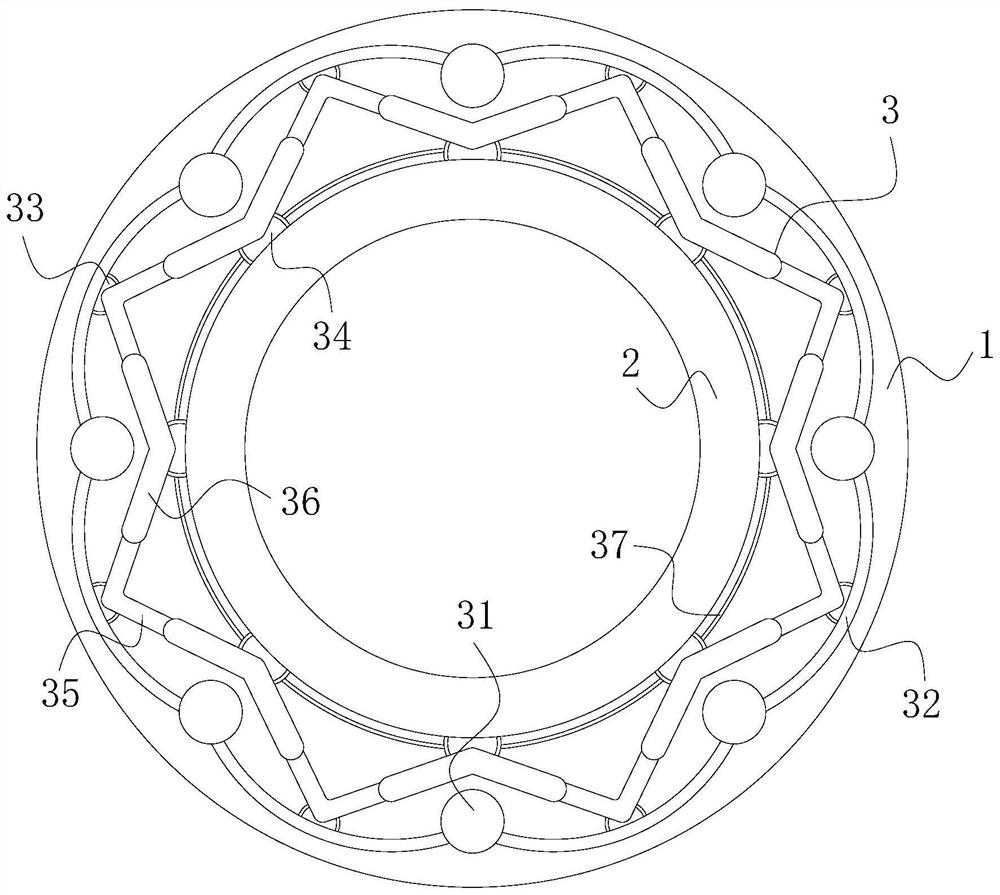

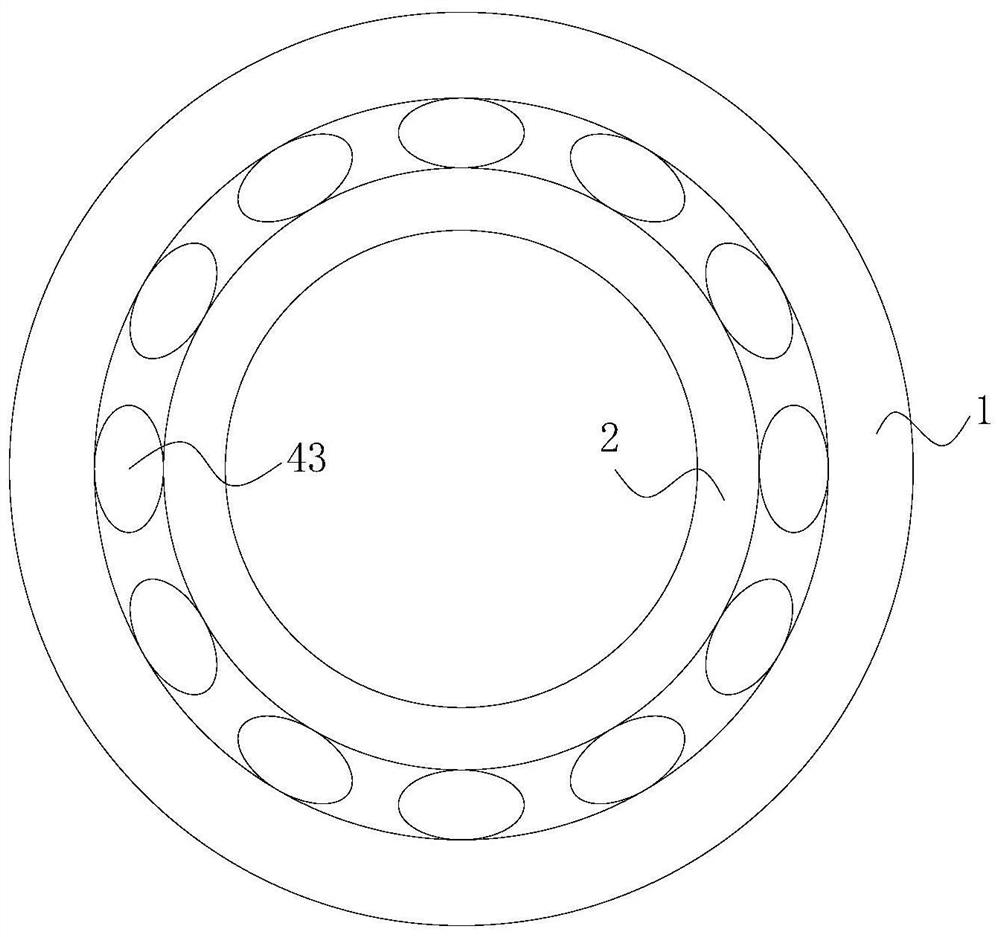

[0018] use Figure 1-Figure 4 A polyethylene gas pipe according to one embodiment of the present invention will be described below.

[0019] Such as Figure 1-Figure 4 As shown, a polyethylene gas pipe according to the present invention includes an outer pipe 1, an inner pipe 2, an explosion-proof mechanism 3 and a linkage mechanism 4; the outer pipe 1 is sleeved on the outside of the inner pipe 2, and the outer pipe 1 and the A certain cavity is left between the inner tubes 2, the outer tube 1 and the inner tube 2 are made of polyethylene material, and an explosion-proof mechanism 3 is arranged between the outer tube 1 and the inner tube 2; the explosion-proof mechanism 3 includes a fixed rod 31 , mounting plate 32, No. 1 buffer bag 33, No. 2 buffer bag 34, No. 1 connecting frame 35, No. 2 connecting frame 36 and coating 37; the inner wall of the outer tube 1 is uniformly fixedly connected with a fixed rod 31; A mounting plate 32 is fixedly connected between the two fixed r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap