Full-automatic solid-liquid thickening separator

A fully automatic separator technology, applied in the separation method, filtration separation, sedimentation separation, etc., can solve the problem that the solid-liquid separator cannot be graded and settled, and achieve the effect of reducing labor costs and potential safety hazards, reducing costs, and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

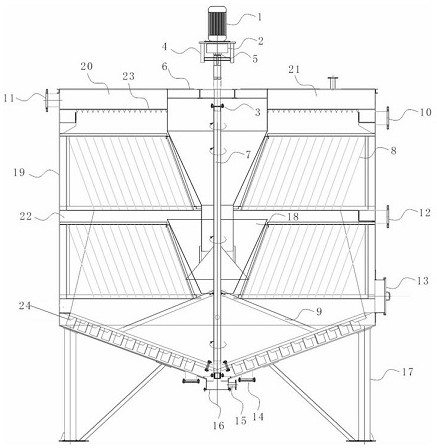

[0025] refer to figure 1 , a fully automatic solid-liquid thickening separator in this embodiment includes a device casing 19, a first mixing box 20 and a second mixing box 21, and the first mixing box 20 and the second mixing box 21 are installed on the top of the device casing 19. The two ends of the first mixing box 20 and the second mixing box 21 are connected through the installation bottom cover 6; the side wall of the first mixing box 20 is provided with a clear liquid outlet 11, and the second mixing box 21 A mixed liquid inlet 10 is opened on the side wall, and a filter screen 23 is arranged in the first mixing box 20 and the second mixing box 21;

[0026] The bottoms of the first mixing box 20 and the second mixing box 21 are sequentially provided with a first settling zone and a second settling zone; one side of the device shell 19 is provided with a liquid taking port 12, and the liquid taking port 12 is located in the first settling zone. zone and the second sett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com