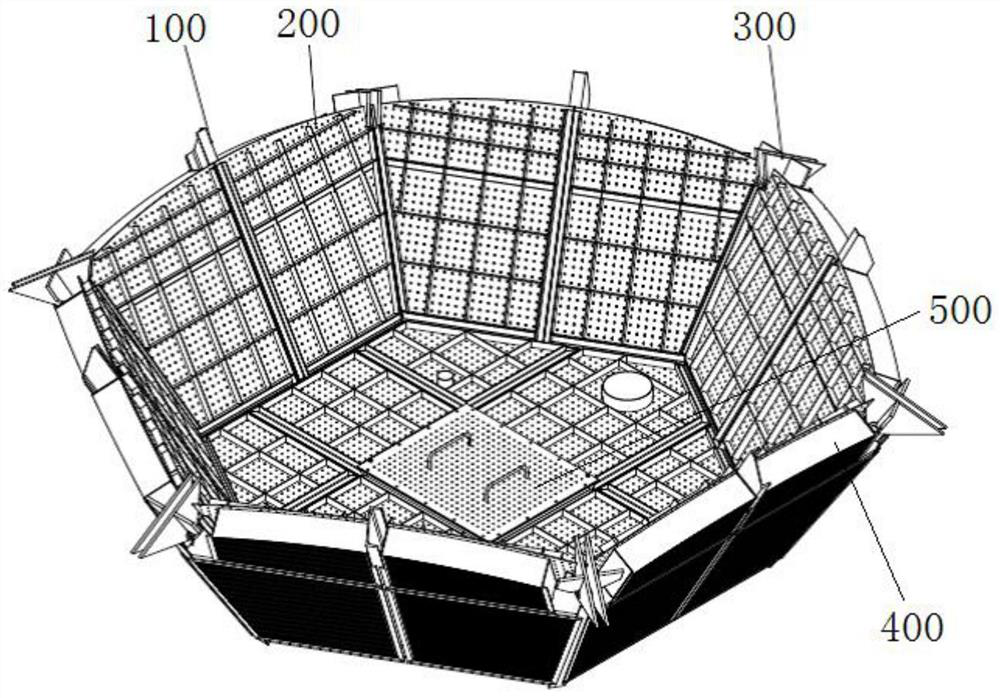

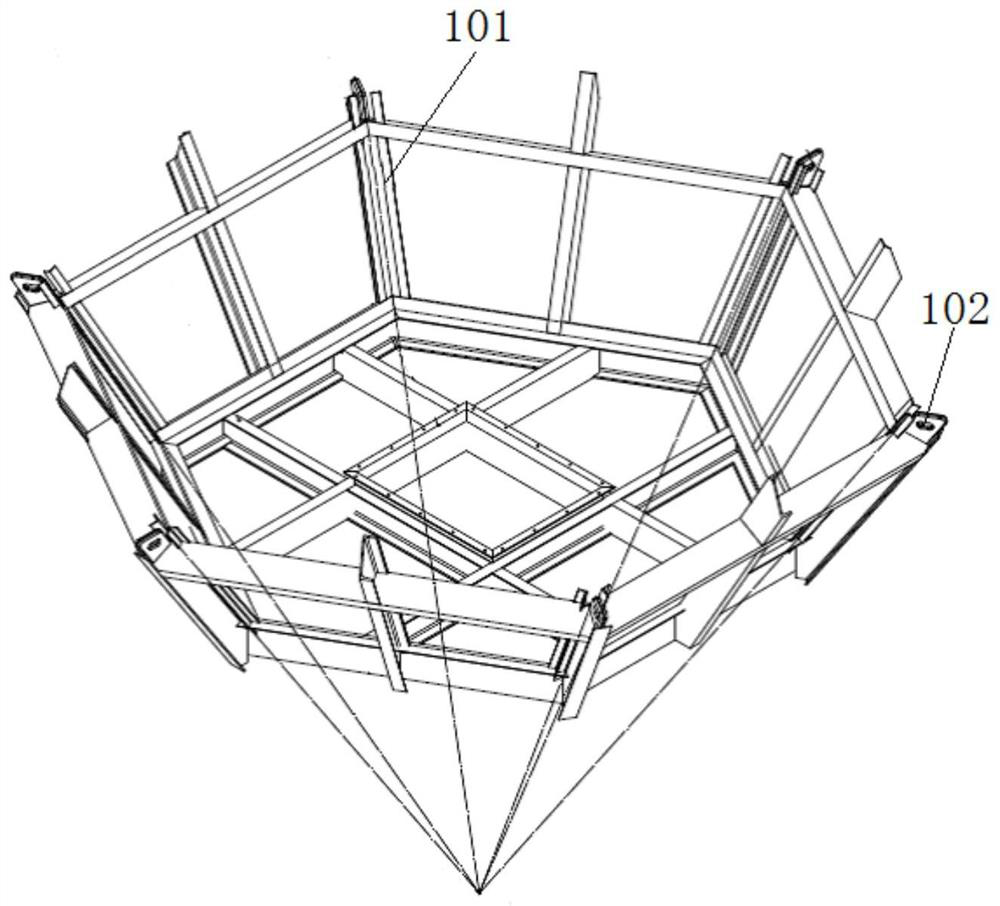

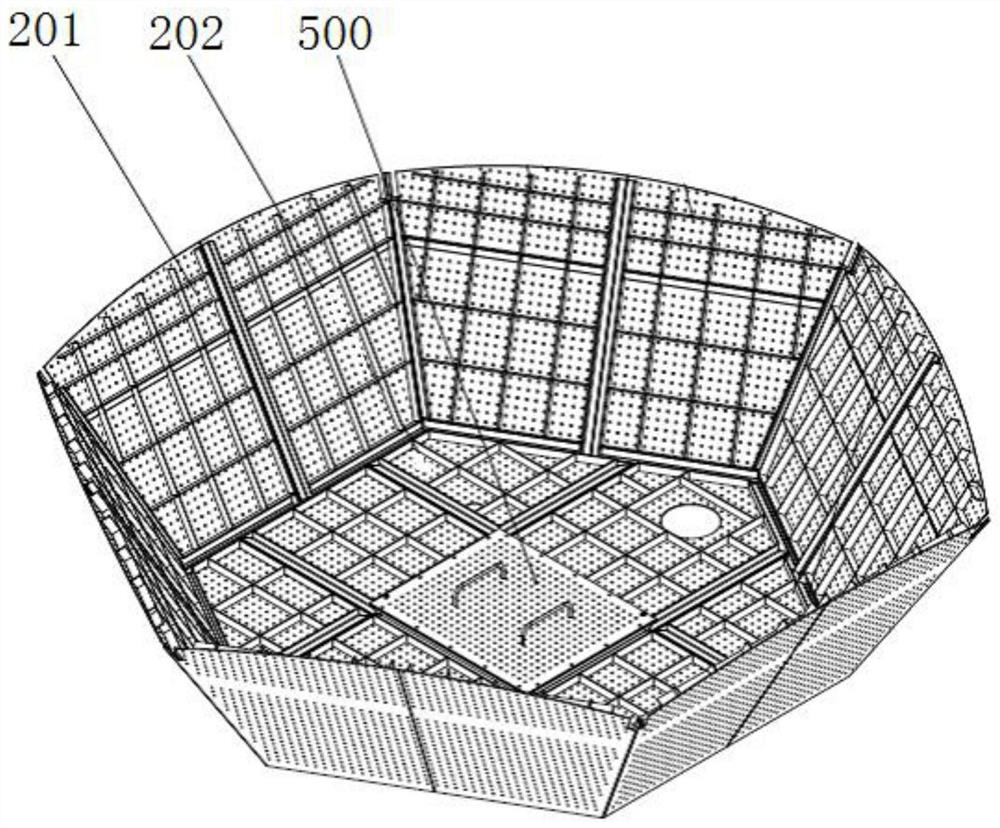

Steam-water separation device for spherical tank heat accumulator

A technology of steam-water separation device and heat accumulator, which is applied in the direction of steam separation device, steam generating device, separation method, etc., can solve the problem that the steam-water separation device cannot well adapt to the requirements of spherical tank heat accumulator, and achieve easy installation and Subsequent maintenance, simple structure, and convenient mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the present invention will be clearly and completely described below with reference to the embodiments. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Although the representative embodiments of the present invention have been described in detail, those skilled in the art to which the invention pertains will appreciate that various modifications and changes can be made in the invention without departing from the scope of the invention. Therefore, the scope of the present invention should not be limited to the embodiments, but should be defined by the appended claims and their equivalents.

[0026] In the description of the present invention, it should be understood that the terms "center", "upper", "lower", "front", "rear", "left", "right", "vertical", "horizontal", The orientation or positional relationship indicated by "top", "bottom", "inner", "outer", etc. i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com