Integral display screen cleaning equipment and cleaning method

A technology for cleaning equipment and display screens, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., can solve problems such as unclean cleaning, and achieve the effect of improving cleaning and sterilizing effect and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

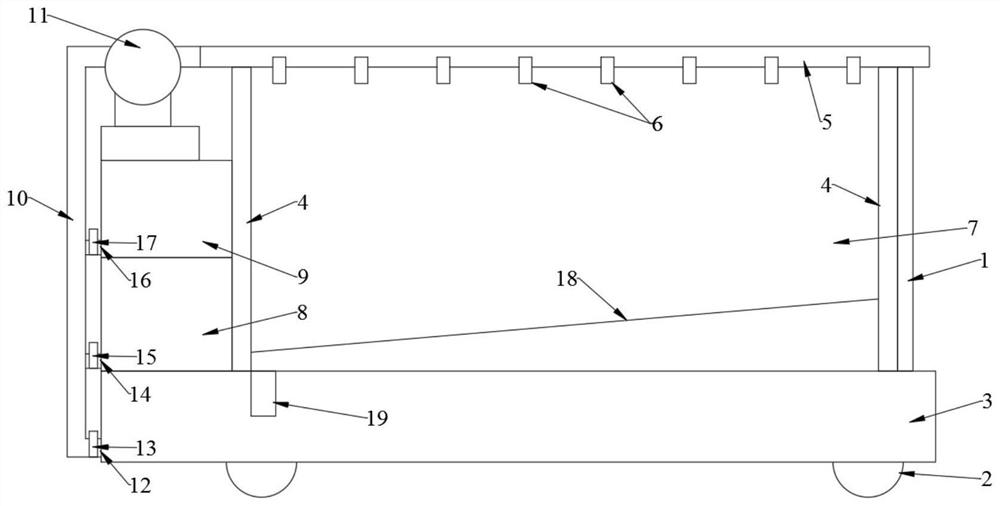

Image

Examples

Embodiment 1

[0017] The components of the cleaning solution A include sodium lauryl sulfate, sodium citrate, n-octanol, laureth, sodium pyrophosphate and water; the components of the cleaning solution B include N-methyl Pyrrolidone, spearmint-lichen-kelp complex extract, ferrous chloride, sodium alginate and hydrogen peroxide. Wherein the preparation method of the spearmint-lichen-kelp compound extract is as follows: the spearmint leaves, lichen leaves and kelp are respectively chopped and mixed into a mixture, and the mixture is prepared according to the mass ratio of material to liquid: material / liquid=1:10. The ratio was added into deionized water, extracted at a constant temperature of 65 ± 5 °C in a water bath for 1 h, condensed and refluxed, filtered, and the filter residue was extracted twice according to the above process, and the three filtrates were combined and concentrated under reduced pressure to 1 / 8 of the volume before the concentration. Spearmint-lichen-kelp complex extrac...

Embodiment 2

[0022] The components of the cleaning solution A include sodium lauryl sulfate, sodium citrate, n-octanol, laureth, sodium pyrophosphate and water; the components of the cleaning solution B include N-methyl Pyrrolidone, spearmint-lichen-kelp complex extract, ferrous chloride, sodium alginate and hydrogen peroxide. The preparation method of the spearmint-lichen-kelp compound extract is as follows: the spearmint leaves, the lichen leaves and the kelp are respectively chopped and mixed into a mixture, and the mixture is in a ratio of material-liquid mass ratio material / liquid=1:10 Add deionized water, extract at 65±5°C water bath at constant temperature for 1 hour, condense and reflux, filter, and repeat the extraction of the filter residue twice according to the above process, combine the three filtrates, and concentrate under reduced pressure to 1 / 8 of the volume before concentration to obtain the residue. Orchid-lichen-kelp complex extract. The components in the cleaning liqu...

Embodiment 3

[0027] The components of the cleaning solution A include sodium lauryl sulfate, sodium citrate, n-octanol, laureth, sodium pyrophosphate and water; the components of the cleaning solution B include N-methyl Pyrrolidone, spearmint-lichen-kelp complex extract, ferrous chloride, sodium alginate and hydrogen peroxide. The preparation method of the spearmint-lichen-kelp compound extract is as follows: the spearmint leaves, the lichen leaves and the kelp are respectively chopped and mixed into a mixture, and the mixture is in a ratio of material-liquid mass ratio material / liquid=1:10 Add deionized water, extract at 65±5°C water bath at constant temperature for 1 hour, condense and reflux, filter, and repeat the extraction of the filter residue twice according to the above process, combine the three filtrates, and concentrate under reduced pressure to 1 / 8 of the volume before concentration to obtain the residue. Orchid-lichen-kelp complex extract. The components in the cleaning liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com