Sectional cooling device for fine adjustment of transverse roll gap of hot-rolled strip

A technology for segmented cooling and hot-rolled strip, applied in the field of roll cooling, to achieve the effect of simple installation method, strong overall structure adaptability, and improved cooling uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

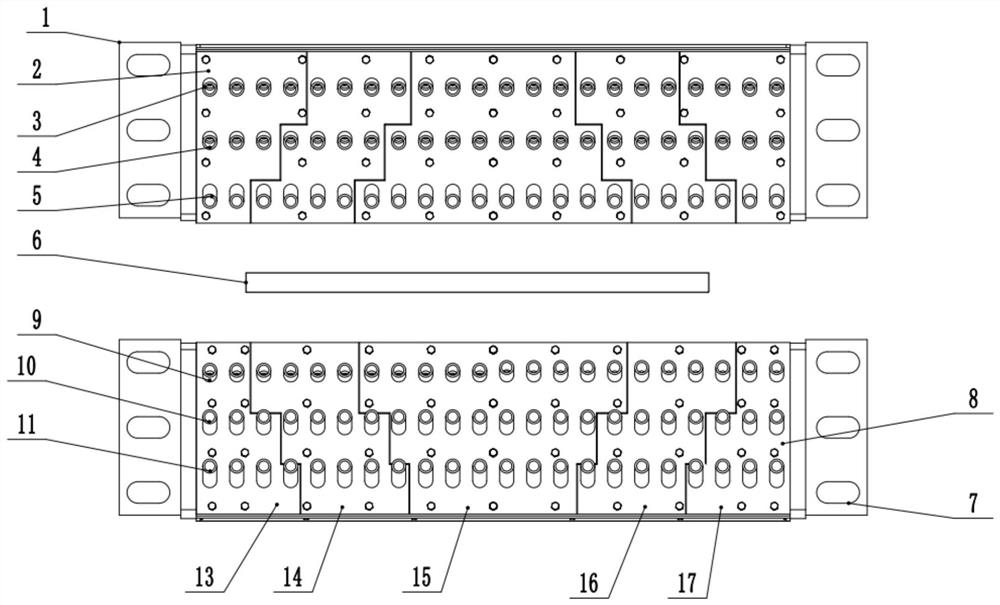

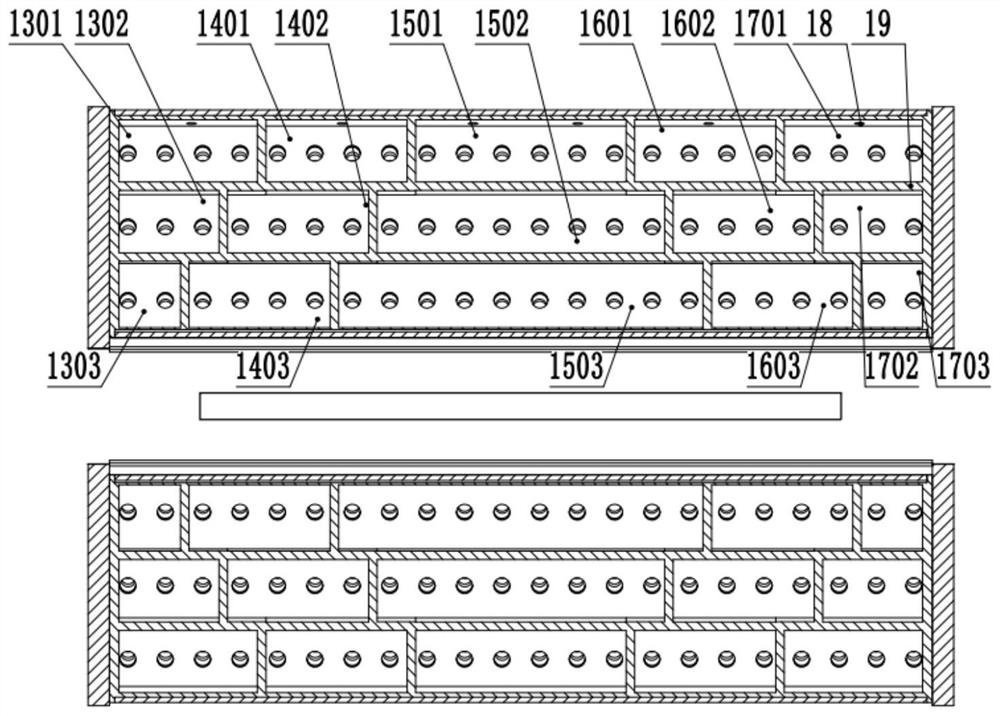

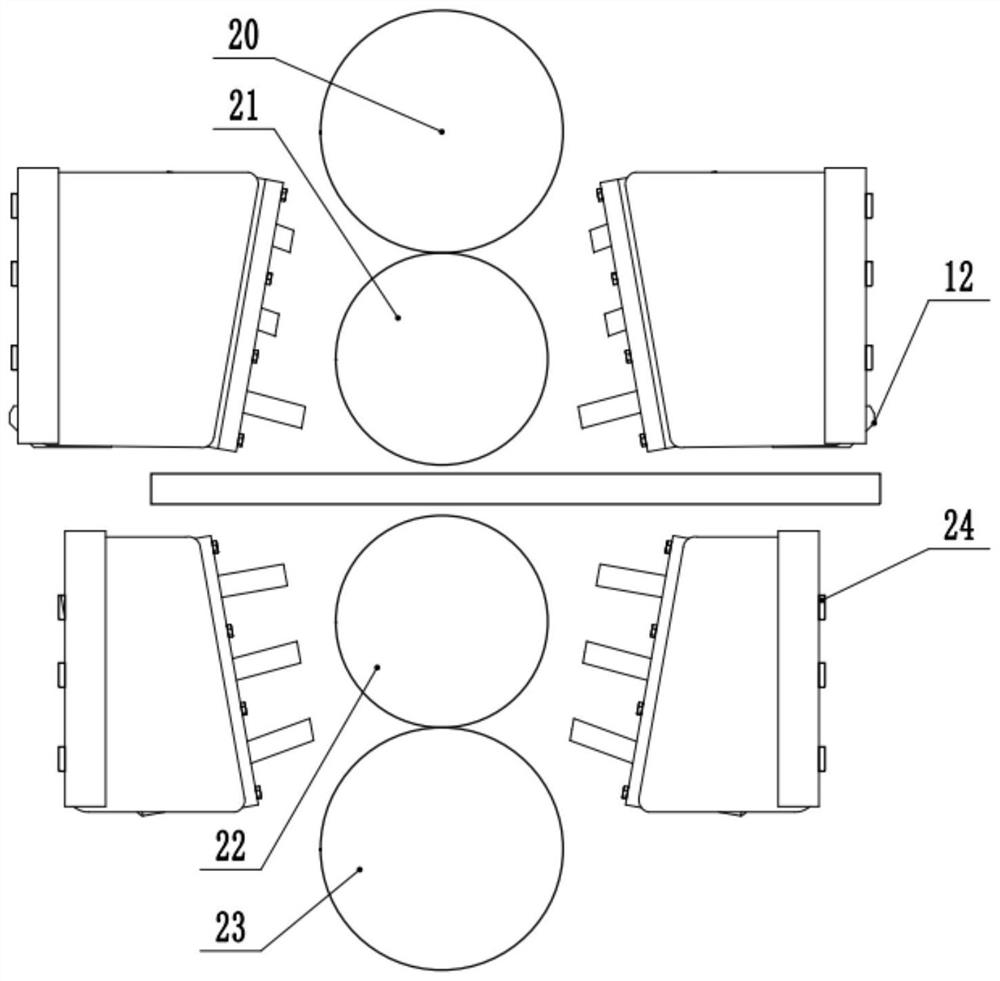

[0041] like Figure 1-4 As shown, the present invention provides a subsection cooling device for fine adjustment of the transverse roll gap of a hot-rolled strip, which can realize subsection cooling of the roll, including a set of cooling beam groups, a connecting pipe 24, a flow regulating valve 25 and an integrated control system ; The connecting pipe 24 is a steel pipe;

[0042] Each set of said chilled beam groups includes two segmented chilled beams symmetrically arranged on the upper and lower sides of the strip steel 6;

[0043] The inner cavity of the segmented cooling beam is divided into three types of cooling zones: a slow cooling zone located at both ends of the segmented cooling beam, a rapid cooling zone located in the middle, and a zone between the slow cooling zone and the rapid cooling zone the basic cooling zone;

[0044] Each of the cooling zones includes three rows of cooling sections that are independent of each other and are arranged in a stepped manne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com