Machining method for milling cutter collet of numerical control machine tool

A technology of numerical control machine tools and processing methods, which is applied in the direction of metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve problems such as unsuitable milling cutters, and achieve the effects of avoiding brittle fracture, strengthening surface quality, and facilitating clamping operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

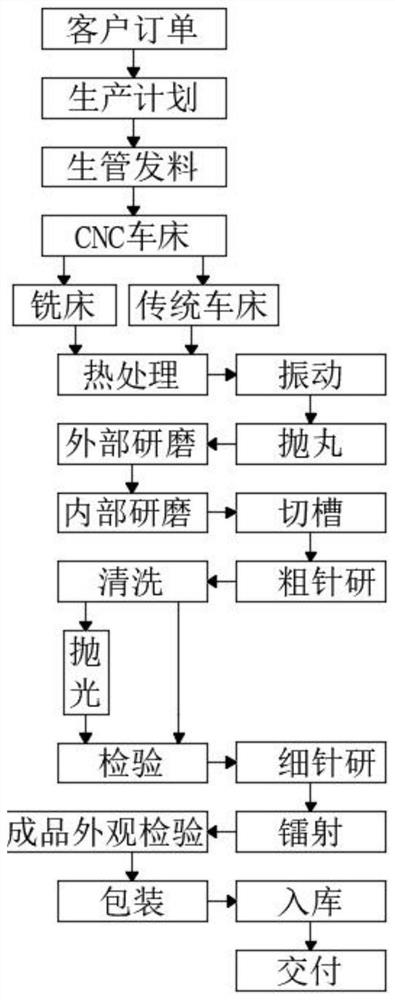

[0030] Example 1, as figure 1 shown:

[0031] A method for processing a milling cutter collet of a CNC machine tool, comprising the following steps:

[0032] Step S1: Preliminary preparation, the customer sends the specifications and technical requirements of the milling cutter collet to establish the order, formulates the production plan and process plan according to the customer's requirements, and distributes the raw pipe raw materials to the CNC lathe to prepare the workpiece for processing;

[0033] Step S2: rough machining of the raw pipe, rough machining the overall surface of the raw pipe collet by a CNC lathe. During rough machining, the inner surface of the raw pipe collet is used as the positioning surface, and the outer surface of the raw pipe collet is turned and processed. Ensure the coaxiality between the outer surface and the inner surface of the pipe clamp, and then perform rough machining on the tapered end face of the pipe clamp to ensure that the machining...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com