FRP biomass composite component with circular exterior and square interior and manufacturing method

A manufacturing method and technology of composite components, applied in the field of building component manufacturing, can solve problems such as low bearing capacity, low strength anisotropy, limitations, etc., and achieve the effects of reducing self-weight, improving appearance, and increasing utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

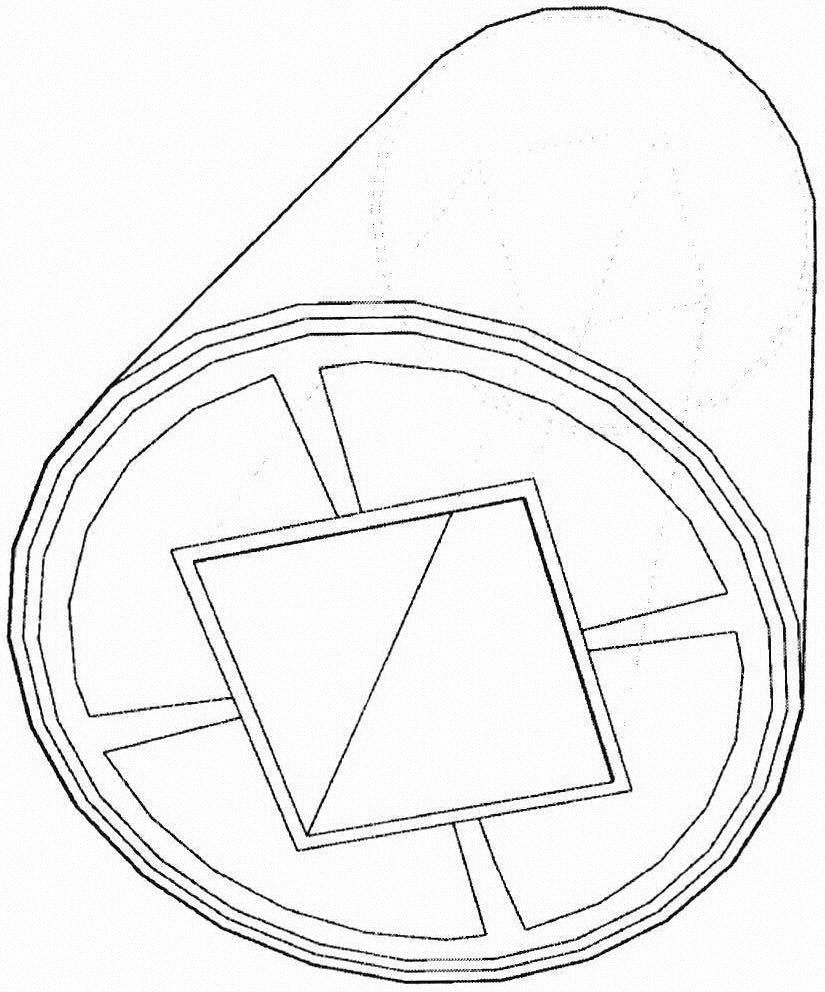

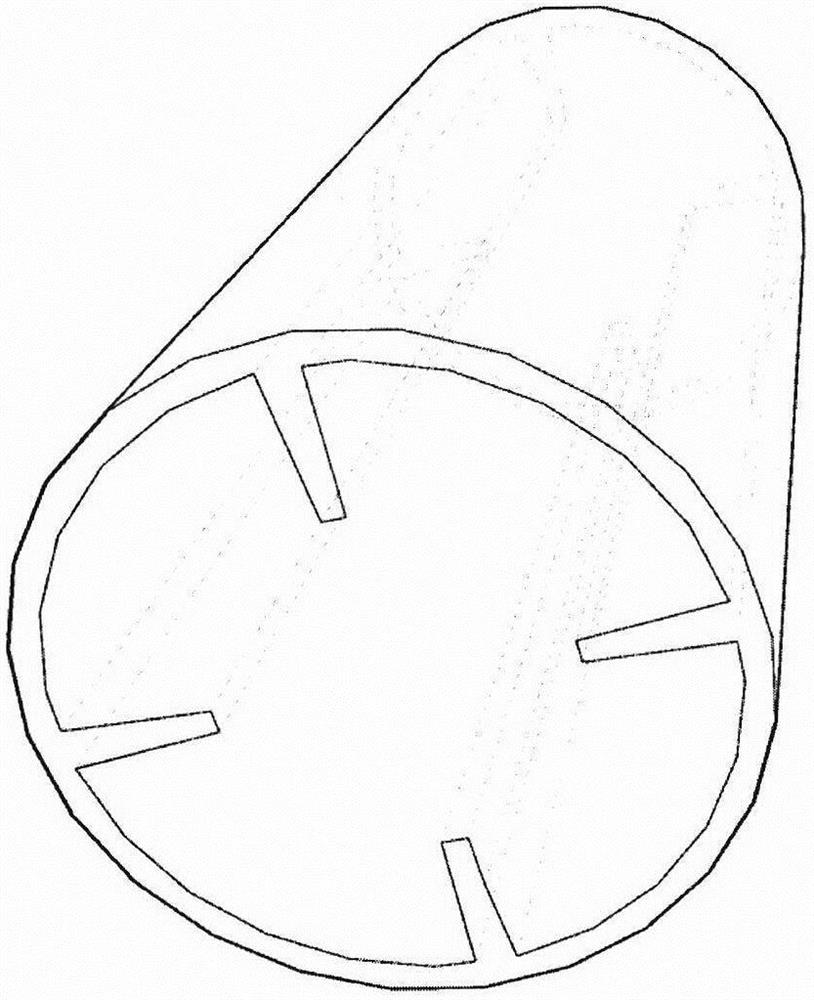

[0014] The overall structure of the composite column made by the present invention is as follows: Figure 1 shown, a hollow ribbed thin-walled steel cylinder such as Figure 2 Show.

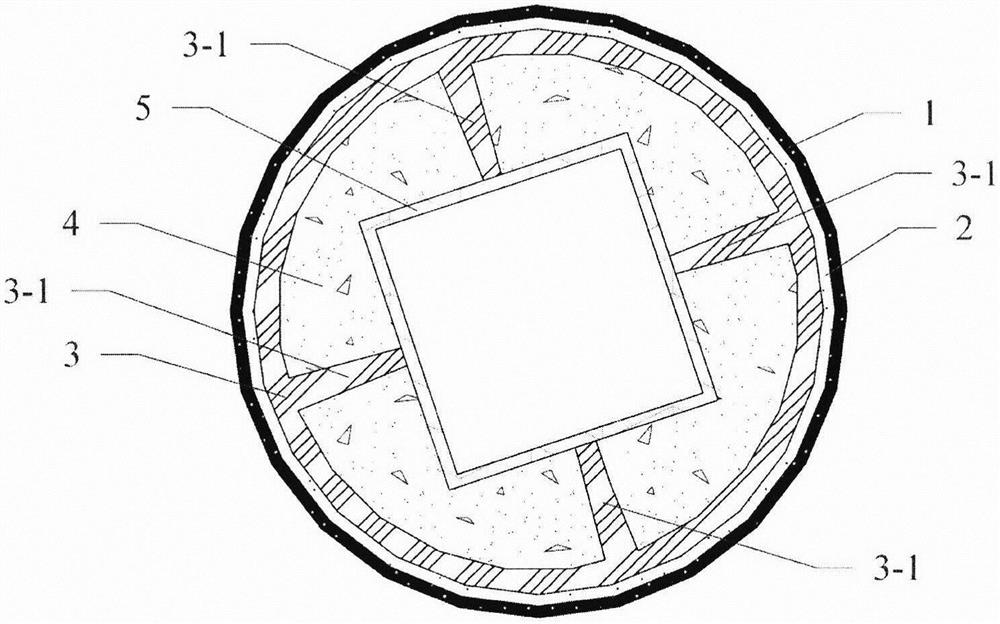

[0015] A kind of outer circle inner square FRP biomass composite component and manufacturing method, such as image 3 , the composite components are, from outside to inside, the bamboo layer (1), the gypsum layer (2), the hollow ribbed thin-walled steel cylinder (3), the biomass material (4) and the FRP profile square cylinder (5); image 3 , and its manufacturing method is as follows: firstly, it is cast into a hollow ribbed thin-walled steel cylinder (3) at one time in the factory, and four steel ribs (3-1) are evenly distributed inside the hollow ribbed thin-walled steel cylinder (3), and the steel ribs (3-1) The thickness of the steel rib (3-1) is not less than 5mm; the FRP profile square cylinder (5) is placed inside the hollow ribbed thin-walled steel cylinder (3), and the FRP profile Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com