Environment-friendly automatic intelligent treatment device for drying graphite by using clean energy

A technology of processing device and clean energy, applied in drying gas arrangement, drying solid materials, drying chamber/container, etc., can solve the problems of uneven heating inside and outside graphite, poor drying efficiency of graphite, insufficient drying, etc., to reduce heat loss , good drying effect, improve drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

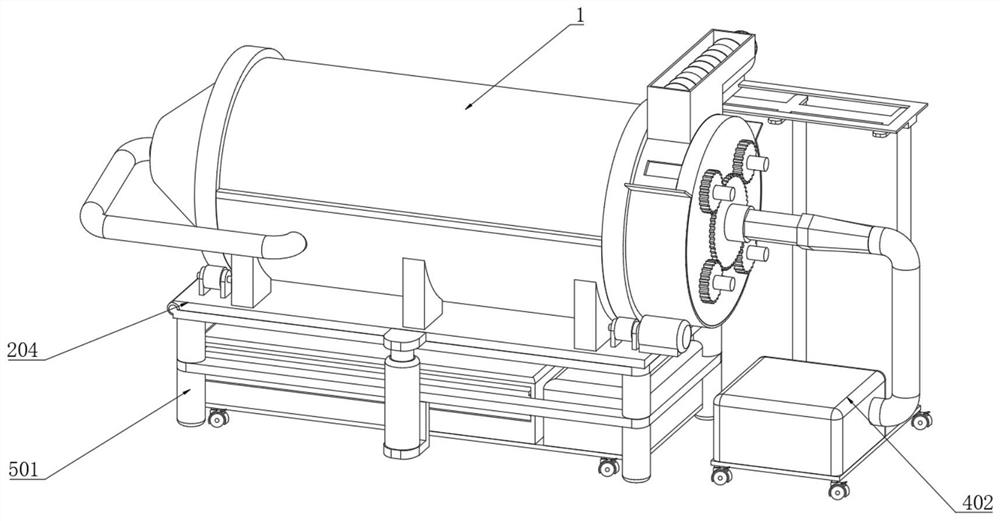

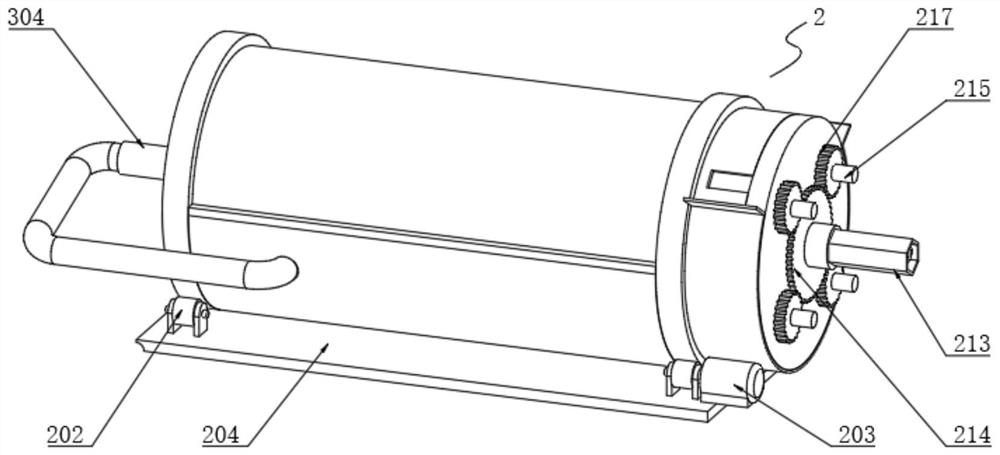

[0044] Example: as figure 1 As shown, the present invention provides a technical solution for an environmental protection automatic intelligent processing device applying clean energy to dry graphite, including:

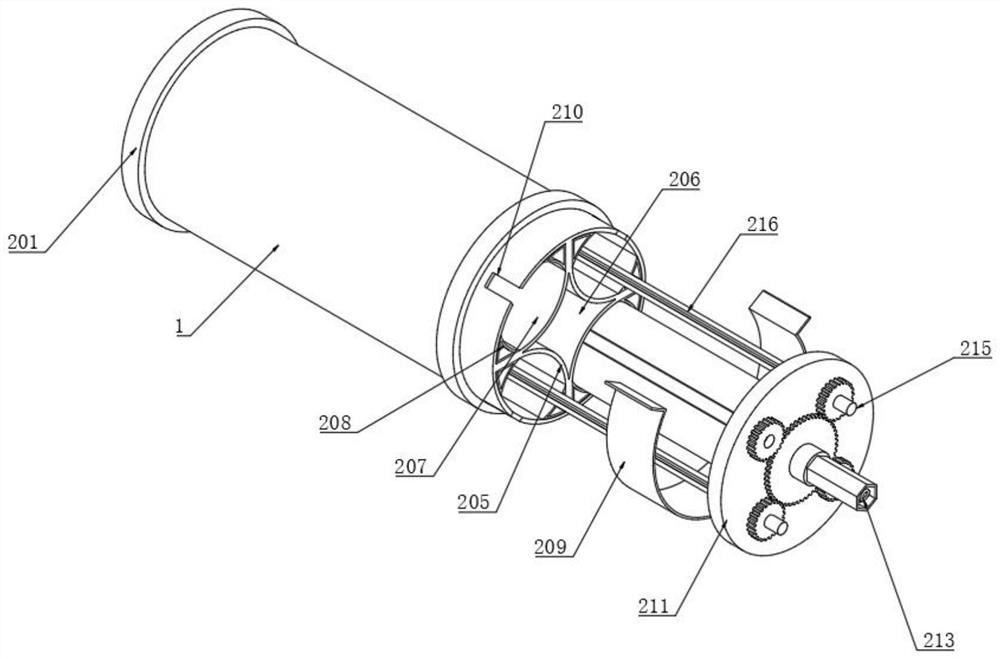

[0045] The uniform drying component 2 is used to heat and dry the graphite. During the heating process, the graphite is separated by the separator 205, and the stirring of the soft brush 216 is used, and then the heating position is increased through the auxiliary heating chamber 208, so as to achieve the purpose of heating more uniformly and quickly;

[0046] The waste heat utilization component 3 is used to utilize the waste heat. The exhaust gas enters the space between the drying cylinder 1 and the semi-circular cover 306 through the connecting pipe 309, heats the outside of the drying cylinder 1, and keeps the drying cylinder 1 warm, so as to reduce the internal heat loss and improve the efficiency of the drying cylinder. drying effect;

[0047] The feeding com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com