Low-GI fish maw porridge and preparation method thereof

A technology for fish maw and coarse grains, applied in the field of food processing, can solve the problems of inability to guarantee food ratio and nutritional balance, easily exceeding the GI value, etc., and achieve the effects of promoting gastrointestinal motility, reducing high cholesterol and facilitating defecation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

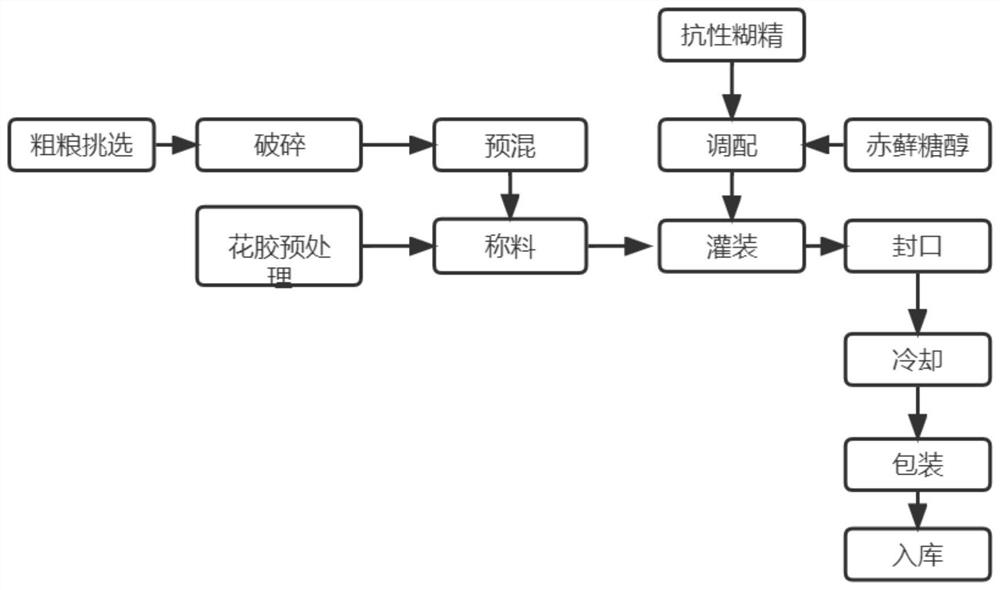

Method used

Image

Examples

Embodiment 1

[0045] Raw materials: 1.0 parts of fish maw, 3.5 parts of erythritol, 1.5 parts of resistant dextrin, 4 parts of quinoa, 2.5 parts of oats, 2 parts of white kidney beans and 1.8 parts of chickpeas and 85 parts of water.

[0046] S11. Select quinoa, oats, white kidney beans and chickpeas to remove impurities, wherein the white kidney beans and chickpeas are crushed to a particle size of 4-8 mm, and the quinoa, oats and crushed white kidney beans and chickpeas are Beans are premixed to obtain premixed coarse grains;

[0047] S12, using purified water to prepare erythritol and resistant dextrin to obtain a preparation solution;

[0048] S13. Using an electronic balance with an accuracy of 0.01g, in a clean metal bowl, according to the above proportions, sequentially weigh the fish maw, the pre-mixed coarse grains and the preparation liquid for filling, wherein the temperature of the material and liquid should be greater than 60 ℃, and sealing is performed after filling to obtain...

Embodiment 2

[0051] Raw materials: 0.8 parts of fish maw, 3 parts of erythritol, 1.6 parts of resistant dextrin, 5 parts of quinoa, 3 parts of oats, 2.5 parts of white kidney beans and 2 parts of chickpeas and 80 parts of water.

[0052] S21. Select quinoa, oats, white kidney beans and chickpeas to remove impurities, wherein the white kidney beans and chickpeas are crushed to a particle size of 4-8 mm, and the quinoa, oats and the crushed white kidney beans and chickpeas are Beans are premixed to obtain premixed coarse grains;

[0053] S22, using purified water to prepare erythritol and resistant dextrin to obtain a preparation solution;

[0054] S23. Using an electronic balance with an accuracy of 0.01g, in a clean metal bowl, according to the above proportions, sequentially weigh the fish maw, the pre-mixed coarse grains and the preparation liquid for filling, wherein the temperature of the material liquid should be greater than 60 ℃, and sealing is performed after filling to obtain low...

Embodiment 3

[0057] Raw materials: 1.2 parts of fish maw, 3.5 parts of erythritol, 1.6 parts of resistant dextrin, 5 parts of quinoa, 2.5 parts of oats, 2.5 parts of white kidney beans and 2 parts of chickpeas and 85 parts of water.

[0058] S31. Select quinoa, oats, white kidney beans and chickpeas to remove impurities, wherein the white kidney beans and chickpeas are crushed to a particle size of 4-8 mm, and the quinoa, oats and the crushed white kidney beans and chickpeas are Beans are premixed to obtain premixed coarse grains;

[0059] S32, using purified water to prepare erythritol and resistant dextrin to obtain a preparation solution;

[0060] S33. Using an electronic balance with an accuracy of 0.01g, in a clean metal bowl, according to the above proportions, sequentially weigh the fish maw, the pre-mixed coarse grains and the preparation liquid for filling, wherein the temperature of the material and liquid should be greater than 60 ℃, and sealing is performed after filling to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com