Feeding device for production of isopentenol

A technology of isoprenol and feeding device, applied in feeding device, organic chemistry, chemical instruments and methods, etc., can solve problems such as inconvenience and mixing work, and achieve the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

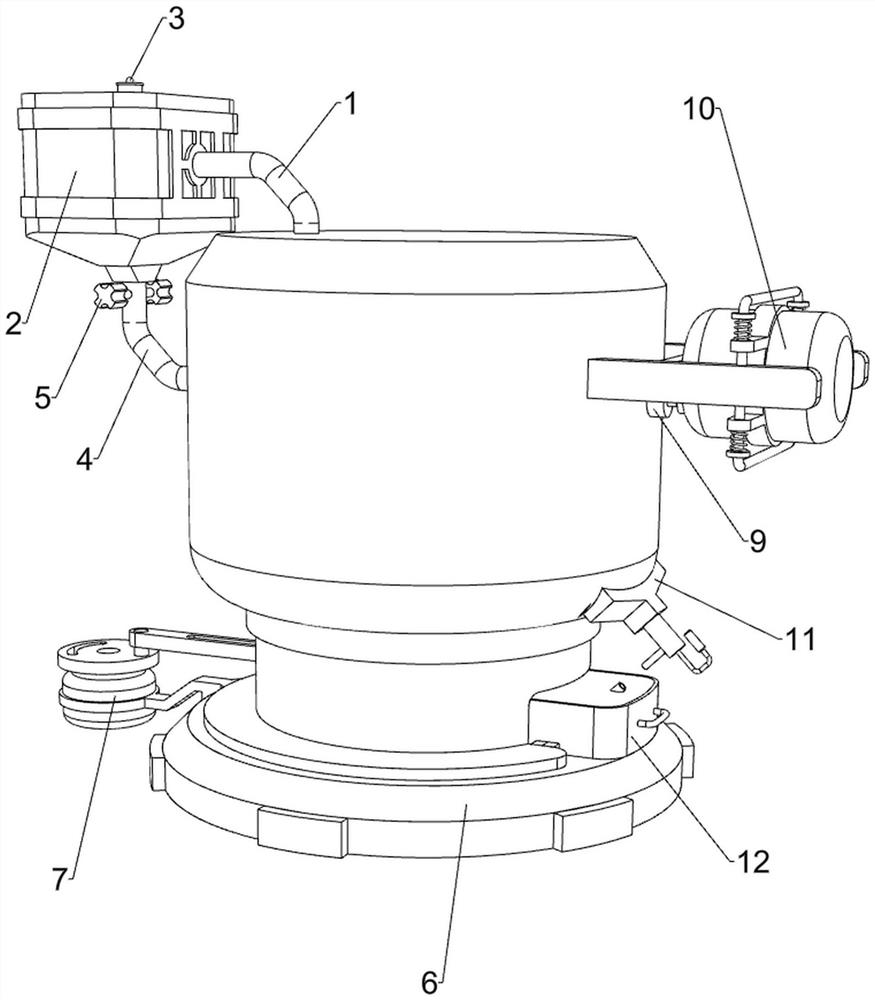

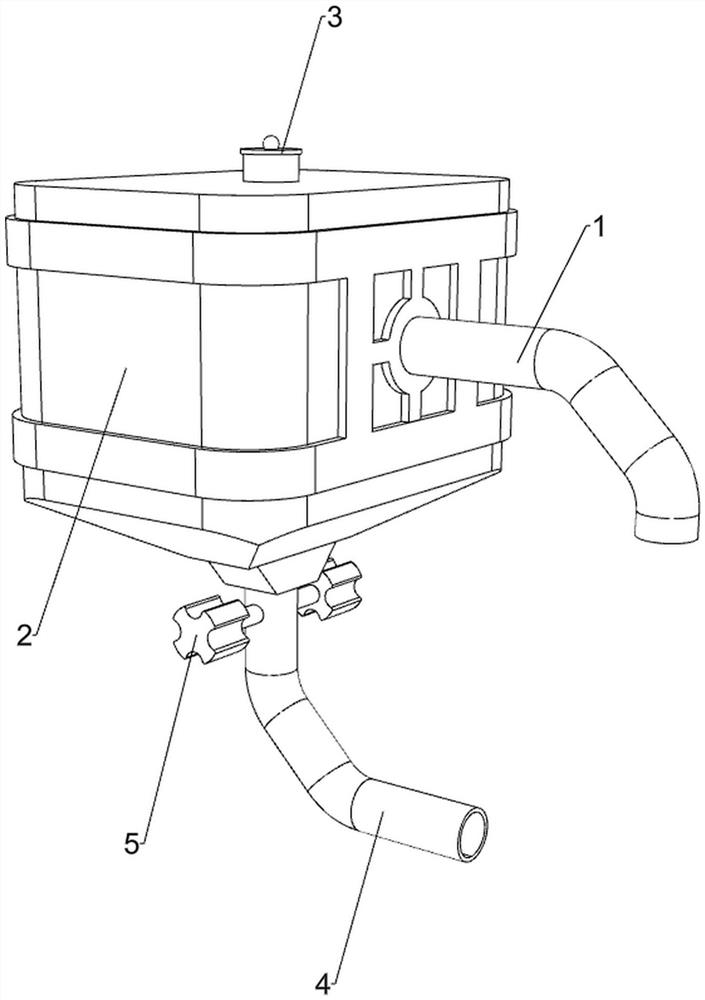

[0033] A feed device for the production of isoprenol, refer to figure 1 and figure 2 , including a first support rod 1, a liquid storage frame 2, a cover 3, a feeding pipe 4, a ball valve 5 and a stirring mechanism 6, and the left side of the first support rod 1 is connected to temporarily store methyl, butene and alcohol. Frame 2, the top of the liquid storage frame 2 is connected with a cover 3 by means of threads, the bottom of the liquid storage frame 2 is connected with a feeding pipe 4 for feeding, and a ball valve 5 is rotatably connected to the upper part of the feeding pipe 4. A stirring mechanism 6 is connected between the right side of the support rod 1 and the right side of the feeding tube 4 .

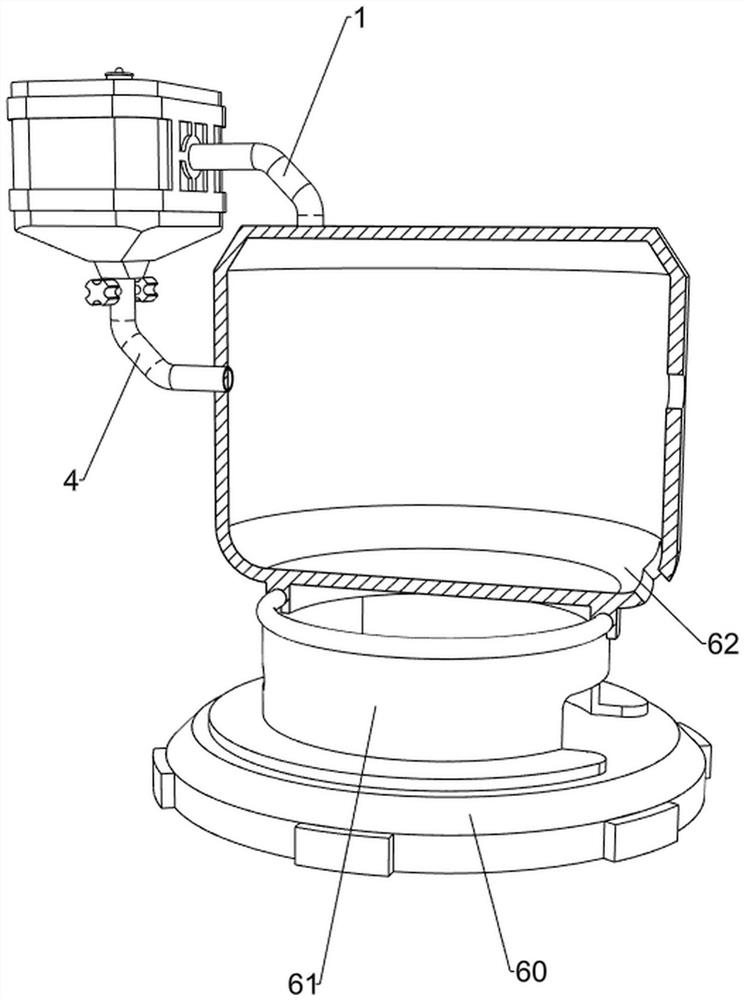

[0034] refer to image 3 , the stirring mechanism 6 includes a chassis 60, a first fixed ring 61 and a rotating frame 62, the top of the chassis 60 is connected with a first fixed ring 61 by welding, and the top of the first fixed ring 61 is rotatably connected with a r...

Embodiment 2

[0037] On the basis of Example 1, refer to figure 1 and Figure 4 , also includes a rotating mechanism 7, the rotating mechanism 7 includes a first support frame 70, a motor 71, a first turntable 72, a connecting rod 73 and a second turntable 74, the left side of the chassis 60 is connected with a first support frame 70, the first A motor 71 is installed on the support frame 70, the output shaft of the motor 71 is connected with a first turntable 72, the top of the first turntable 72 is rotatably connected with a connecting rod 73, and the bottom of the rotating frame 62 is rotatably connected with a second turntable 74 in the middle. The second turntable 74 can drive the rotating frame 62 to rotate, and the second turntable 74 is rotatably connected to the other end of the connecting rod 73 .

[0038] When the methyl, butene and alcohol need to be mixed, the motor 71 can be started, the output shaft of the motor 71 drives the first turntable 72 to rotate, the first turntable...

Embodiment 3

[0040] On the basis of Example 2, refer to Figure 5 , also includes a heating mechanism 8, the heating mechanism 8 includes a second support rod 80 and a heating pipe 81, the left and right sides of the bottom of the rotating frame 62 are connected with a second support rod 80 by welding, two second support rods 80 A heating pipe 81 is installed on both, and the heating pipe 81 can heat the oil.

[0041] When people pour an appropriate amount of guiding oil into the rotating frame 62, the heating pipe 81 can be activated, and then the heating pipe 81 starts to heat up. The heat generated by the heating pipe 81 will heat the guiding oil. When the guiding oil is heated to When the temperature is suitable, the heating pipe 81 can be turned off, and then the heated guide oil will be mixed with the mixed liquid, so that there is no need to manually add the heated guide oil into the liquid storage frame 2, so as to avoid excessive heating. The guide oil burns people's hands and wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com