Building steel structure perforation dust removal type device and steel structure installation auxiliary equipment

An installation assistance, steel structure technology, applied in drilling/drilling equipment, metal processing equipment, maintenance and safety accessories, etc., can solve problems such as eye damage, delay in construction, a large number of iron filings and dust, and avoid dust. , reduce the impact, easy to install the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

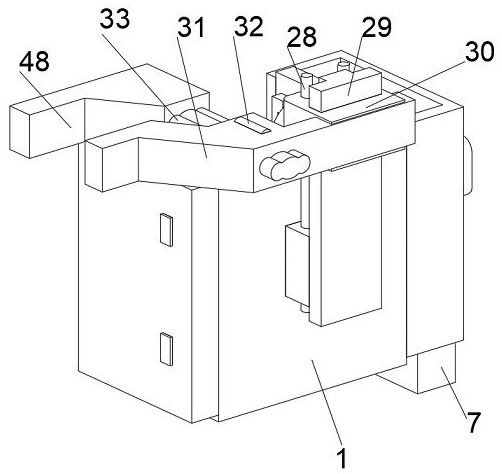

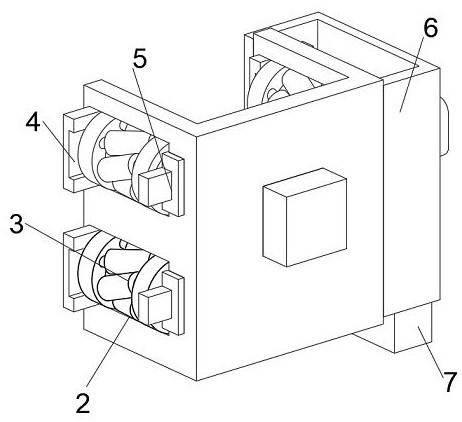

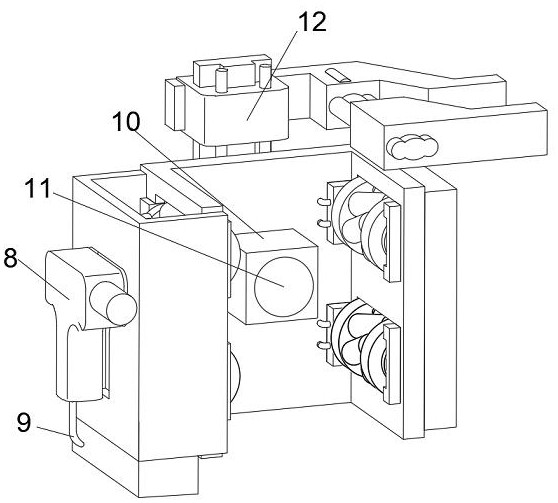

[0030] like Figure 1-6 As shown in the figure, the perforated and dust-removing device for building steel structures and the auxiliary equipment for steel structure installation according to the embodiment of the present invention include an auxiliary frame 1, and two ends of the auxiliary frame 1 are provided with positioning grooves 2. The positioning grooves 2 is provided with a crawling device 3 in the inner middle, one end of the crawling device 3 is provided with a movable bracket 4, and one end of the crawling device 3 away from the movable bracket 4 is provided with a communication device 5, through the setting of the auxiliary frame 1 Fix the device in the middle of the steel structure column, fix the crawler device 3 through the setting of the positioning groove 2, and make one side of the crawler device 3 always in contact with the steel structure column through the setting of the movable bracket 4 and the communication device 5, and pass the crawler device 3. The ...

Embodiment 2

[0033] like Figure 1-6 As shown, the present invention provides a perforation and dust removal device for a building steel structure and an auxiliary equipment for the installation of a steel structure, wherein the crawling device 3 includes a rotating shaft 16 located in the middle of the interior of the positioning groove 2, and two of the rotating shafts 16 A positioning plate 17 is provided at both ends, and one end of the positioning plate 17 on one side is provided with a first bevel gear 18, and the middle of the positioning plate 17 is provided with a number of auxiliary wheels evenly distributed on the outer end of the rotating shaft 16. 19. One side of the auxiliary wheel 19 is provided with a helical gear 20 which penetrates the positioning plate 17 and is matched with the first bevel gear 18, and the outer end of the positioning plate 17 is provided with a protective wheel 21. The setting of the rotating shaft 16 is convenient for positioning and fixing the variou...

Embodiment 3

[0036] like Figure 1-6 As shown, the present invention provides a perforation and dust removal device for a building steel structure and a steel structure installation auxiliary equipment, wherein the perforation shaft 14 includes a third transmission motor 34 located inside the hand-held gun body 13, the third One side of the transmission motor 34 is provided with a first fixed shaft 35 , and one end of the first fixed shaft 35 away from the third transmission motor 34 is provided with a first perforated sleeve 36 . The surface is provided with evenly distributed spiral grooves 37 , the middle of the first fixed shaft 35 is provided with a second fixed shaft 38 , and the side of the second fixed shaft 38 close to the first perforated sleeve 36 is provided with a second fixed shaft 38 . Perforated sleeve 39, several sliding bearings are arranged between the first fixed shaft 35 and the second fixed shaft 38, and an intake turbine is arranged at one end of the first fixed shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com