Penetrating and sleeving system for lead-acid battery panel tube bank

A lead-acid battery and sheathing technology, applied in the direction of lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc. The effect of accurate and reliable pipe threading, less labor occupation, and high threading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

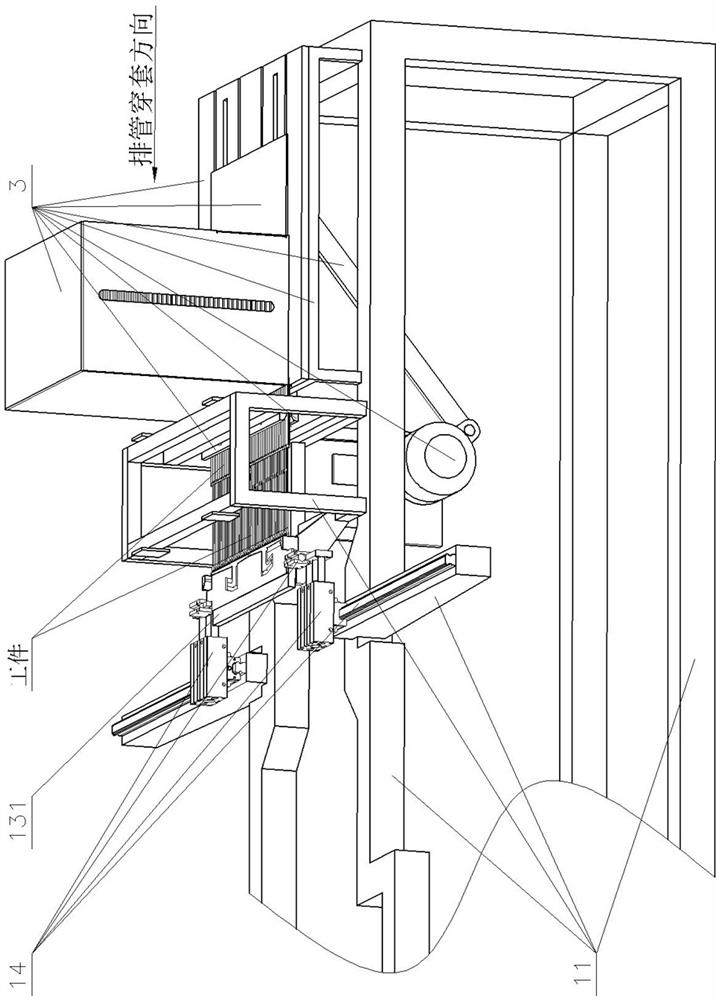

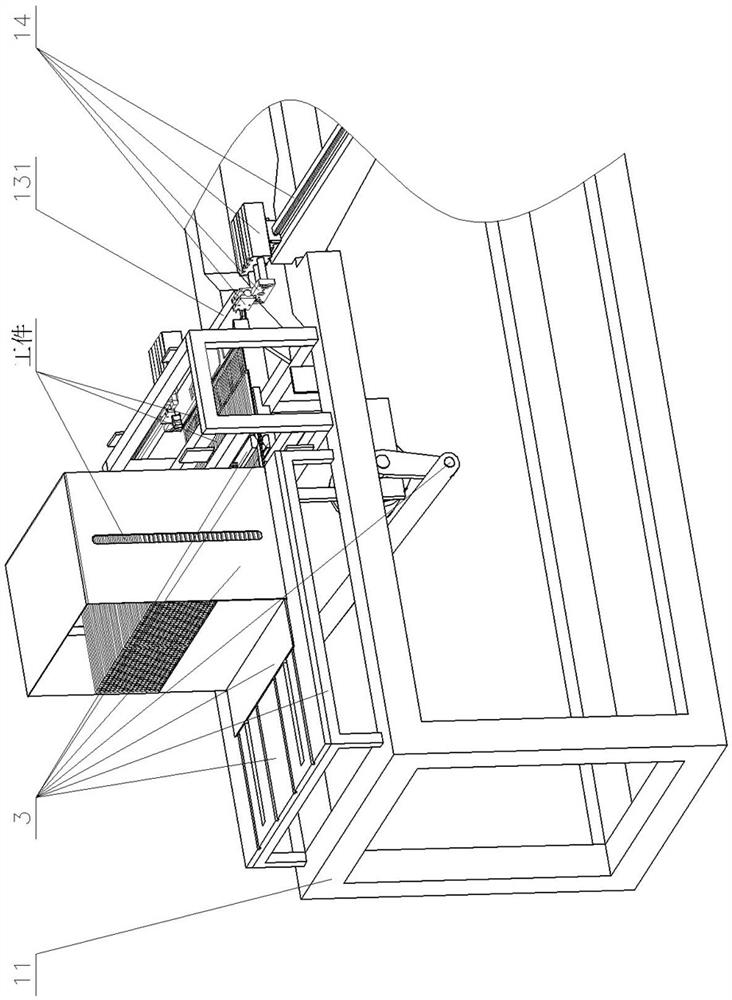

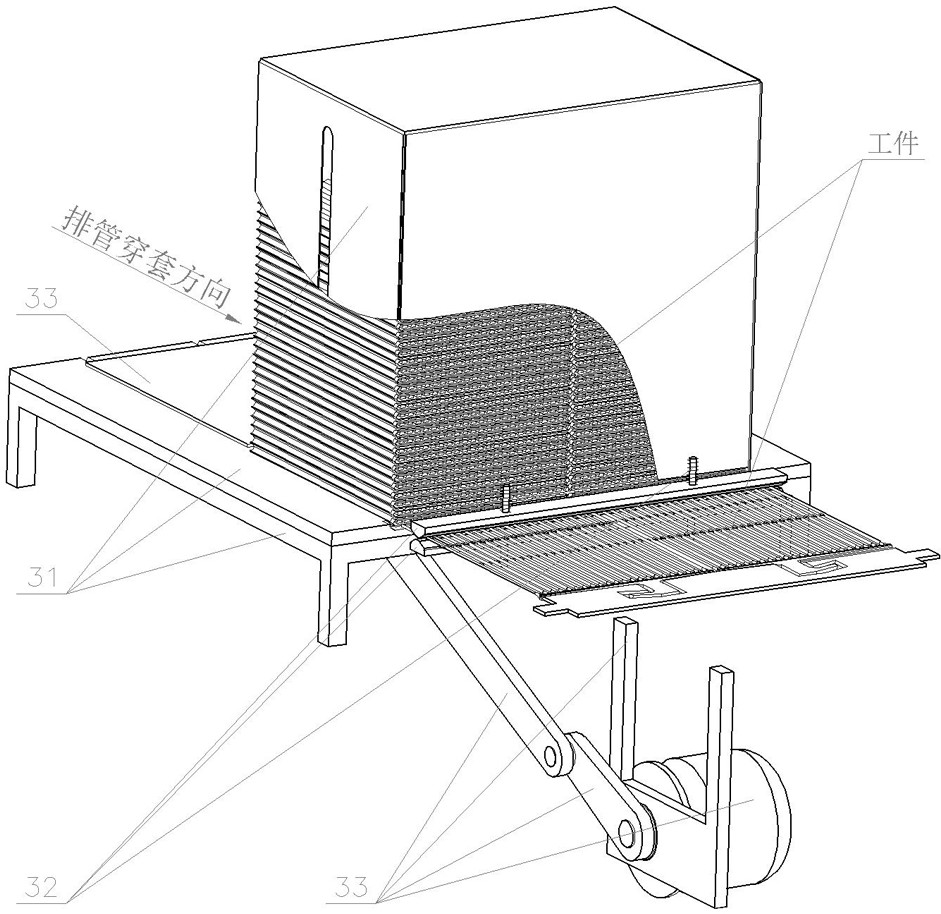

[0031] 11. Frame 110, bottom frame 111, legs I 112, U-shaped frame I 113, beam 114, longitudinal beam 115, mounting plate I 116, mounting plate II 117, support plate 131, positioning plate 14, clamping device 141, Return guide rail 142, return slider 143, clamping cylinder 144, clamping plate 145, finger cylinder 1451, clamping finger 3, pipe threading device 31, threading table 310, threading rack 3101, outrigger Ⅱ311 , platen 3111, semicircular groove 3112, long groove 312, pipe box 3121, observation hole 32, clamping assembly 320, clamping plate 321, guide rod II 322, clamping spring 33, sleeve-through mechanism 330, U-shaped frame II 331, threaded motor 332, threaded crank 333, push tube plate 3331, protruding strips 3332, lugs Ⅴ 334, toggle rod 335, threaded connecting rod.

[0032] exist Figure 1-Figure 16In the illustrated embodiment: the bottom frame 110 of the rack 11 has a regular 4-prism frame structure, one medium-area frame plane of the bottom frame 110 is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com