Preparation process of electronic grade propylene

A preparation process, electronic-grade technology, applied in the field of preparation of electronic-grade propylene, can solve the problems of large amount of extractant, complicated separation process, increased energy consumption, etc., and achieve the effects of reduced energy consumption, good separation effect, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

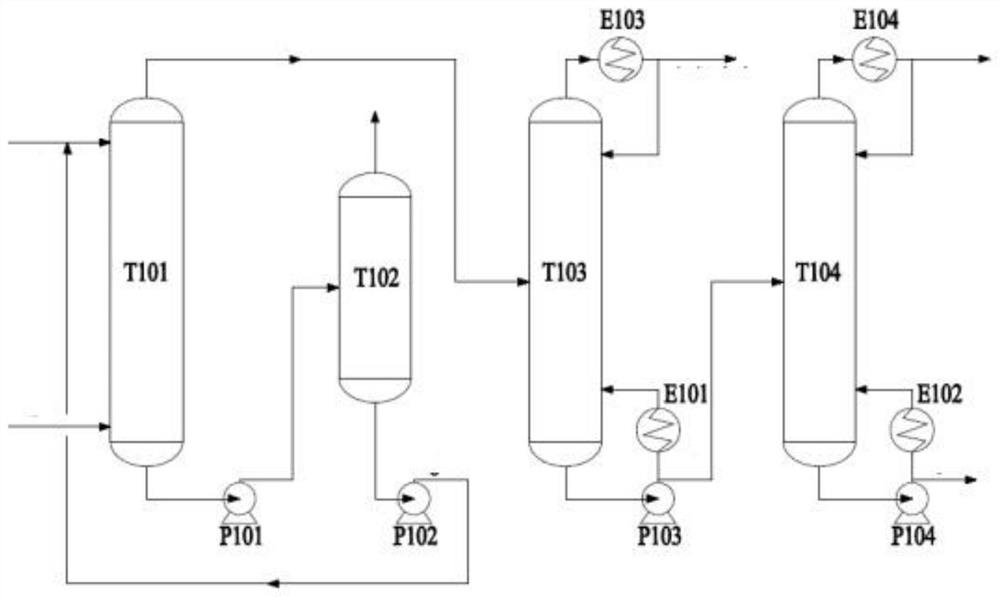

[0036] Example 2, propylene feed gas into the lower part of the washing tower T101 at a flow rate of 100g / min, the extractant cyclohexane into the upper part of the washing tower T101 at a flow rate of 80g / min, the number of theoretical plates of the washing tower T101 is 30 pieces, and the operating pressure is 1.0MPa.

[0037] The bottom of the T101 tower of the washing tower was obtained with a mixture of propane and extractant, passed into the flash tank T102, atmospheric pressure operation, the operating temperature was 5 °C, the top of the flash tank T102 tower was further processed and collected by propane logistics, and the bottom of the flash tank T102 tower was obtained by the pure extractant and regularly recycled into the upper part of the washing tower T101.

[0038] The top of the washing tower T101 gets the propylene that removes propane into the light tower T103, the theoretical plate number is 30, the reflux ratio is 50, the top temperature of the tower is 5 °...

Embodiment 3

[0040] Example 3, propylene feed gas into the lower part of the washing tower T101 at a flow rate of 100g / min, the extractant cyclohexane into the upper part of the washing tower T101 at a flow rate of 150g / min, the number of theoretical plates is 30, and the operating pressure is 1.0MPa.

[0041] The bottom of the t101 tower of the washing tower was obtained with a mixture of propane and extractant, passed into the flash tank T102, atmospheric pressure operation, operating temperature 5 ° C, the top of the flash tank T102 tower was further processed and collected, and the bottom of the flash tank T102 tower was obtained by the pure extractant and regularly recycled into the upper part of the washing tower T101.

[0042] The top of the washing tower T101 obtains the propylene that removes propane into the light tower T103, the theoretical number of plates is 30, the reflux ratio is 50, the top temperature of the tower is 5 °C, and the top pressure of the tower is 1.0MPa.

[00...

Embodiment 4

[0045] Example 4, propylene feed gas, at a flow rate of 100g / min into the lower part of the washing tower T101, the extractant cyclohexane into the upper part of the washing tower T101 at a flow rate of 200g / min, the number of theoretical plates 30, the operating pressure of 1.0MPa.

[0046] The bottom of the t101 tower of the washing tower was obtained with a mixture of propane and extractant, passed into the flash tank T102, atmospheric pressure operation, operating temperature 5 ° C, the top of the flash tank T102 tower was further processed and collected, and the bottom of the flash tank T102 tower was obtained by the pure extractant and regularly recycled into the upper part of the washing tower T101.

[0047] The top of the washing tower T101 obtains the propylene that removes propane into the light tower T103, the theoretical number of plates is 30, the reflux ratio is 50, the top temperature of the tower is 5 °C, and the top pressure of the tower is 1.0MPa.

[0048] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com