Frost-free heat pump system device for reverse-flow reverse-osmosis regeneration and method

A heat pump system and reverse osmosis technology, applied in the field of air conditioning and refrigeration, can solve the problems of difficult to achieve stable coordination between stages, reduce actual operating pressure, and low regeneration efficiency, and achieve the effects of convenient upgrading, avoiding operating pressure, and small equipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

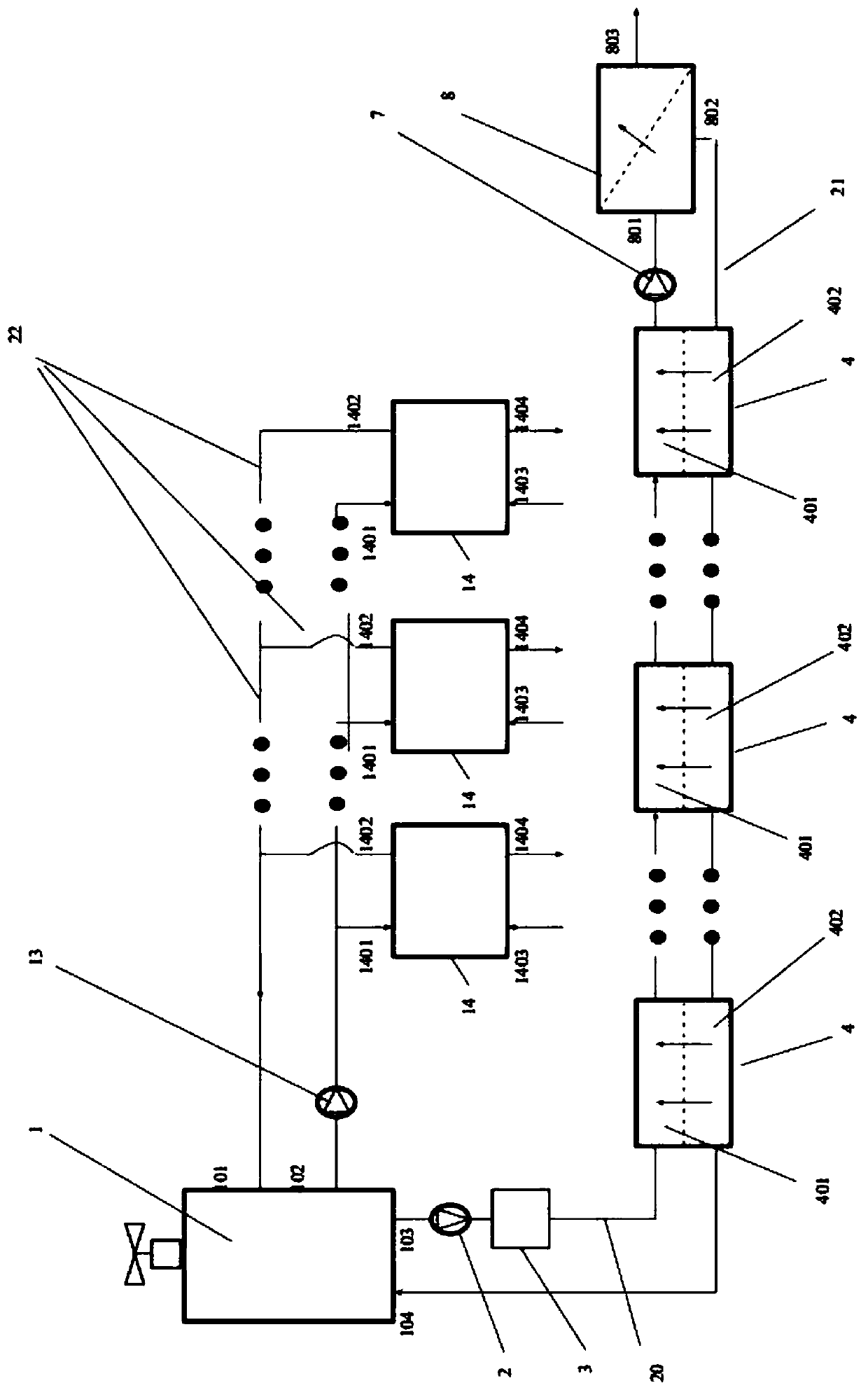

[0074] Embodiment 1, a frost-free heat pump system device type 1 for reverse flow reverse osmosis regeneration, such as figure 1 Shown, including heat pump subsystem I and antifreeze regeneration subsystem II.

[0075] Heat pump subsystem I, the main component for external heating or cooling. It consists of a heat source tower 1, a circulating working medium pump 13, a heat pump host 14 connected in parallel in one or more stages, and a circulating working medium pipeline 22. The circulating working medium pipeline 22 starts from the circulating working medium outlet A102 of the heat source tower 1, and after connecting the circulating working medium pump 13, it is divided into several roads connected in parallel to the circulating working medium inlet B1401 of the heat pump host 14 at each level, and then from the circulating working medium inlet B1401 of the heat pump host 14. After the working medium outlet A1402 comes out, it is connected in parallel to the circulating wo...

Embodiment 2

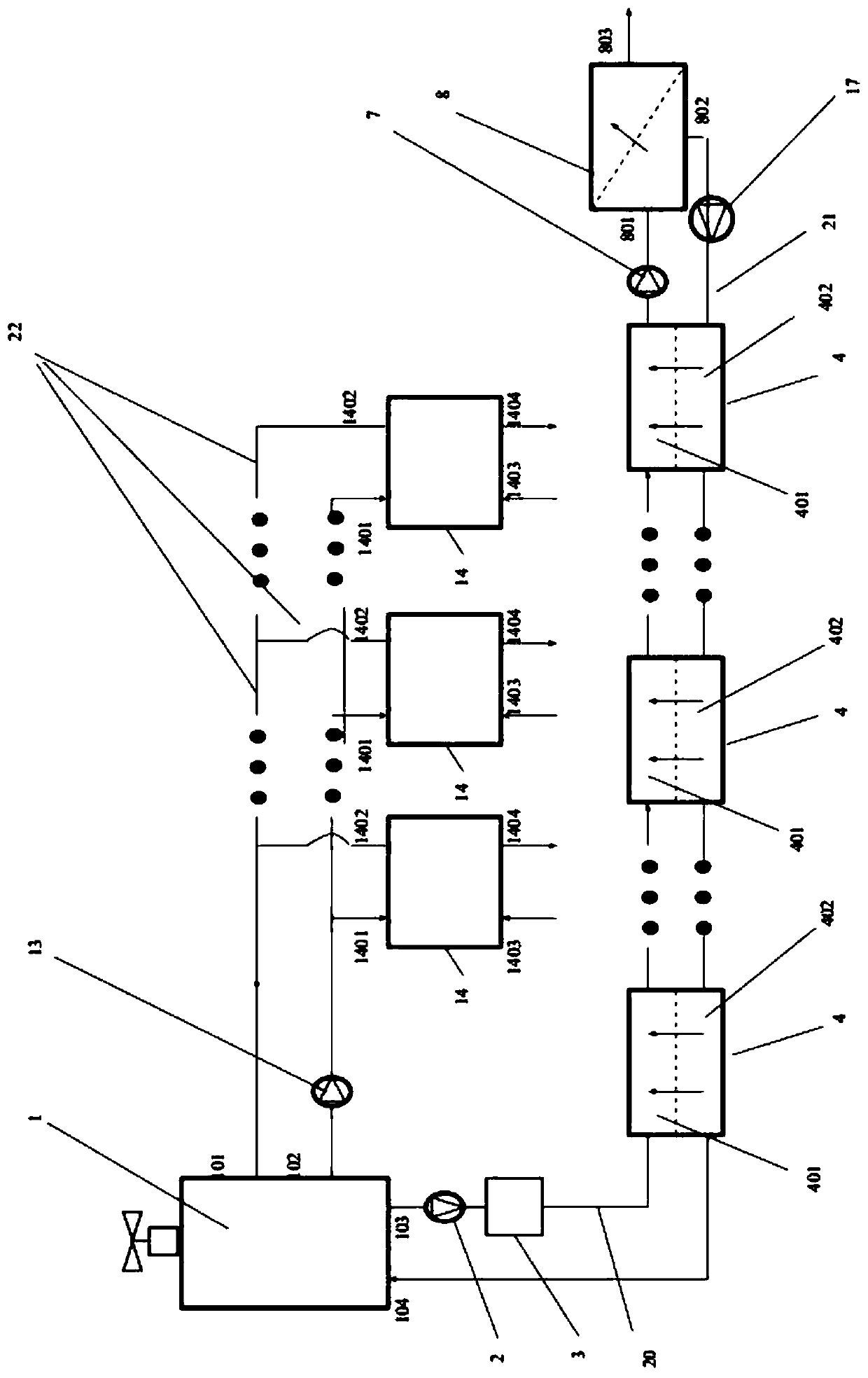

[0091] Embodiment 2, a frost-free heat pump system device type 2 for reverse flow reverse osmosis regeneration, such as figure 2 Shown, including heat pump subsystem I and antifreeze regeneration subsystem II.

[0092] The circulating working fluid and operating mode of the system are the same as in Embodiment 1.

[0093] The structure of heat pump subsystem 1 is the same as that of embodiment 1.

[0094] The structural difference between the antifreeze regeneration subsystem II and the embodiment 1 is: on the basic structure of the antifreeze regeneration subsystem II of the embodiment 1, a device is added between the solution reverse osmosis device 8 and the solution reverse osmosis device 4: reverse osmosis Permeator booster pump 17. That is, the connection of the light-side solution pipeline 20 remains unchanged, and the concentrated-side solution pipeline 21 starts from the solution outlet 802 of the solution reverse osmosis device 8, connects the reverse osmosis boost...

Embodiment 3

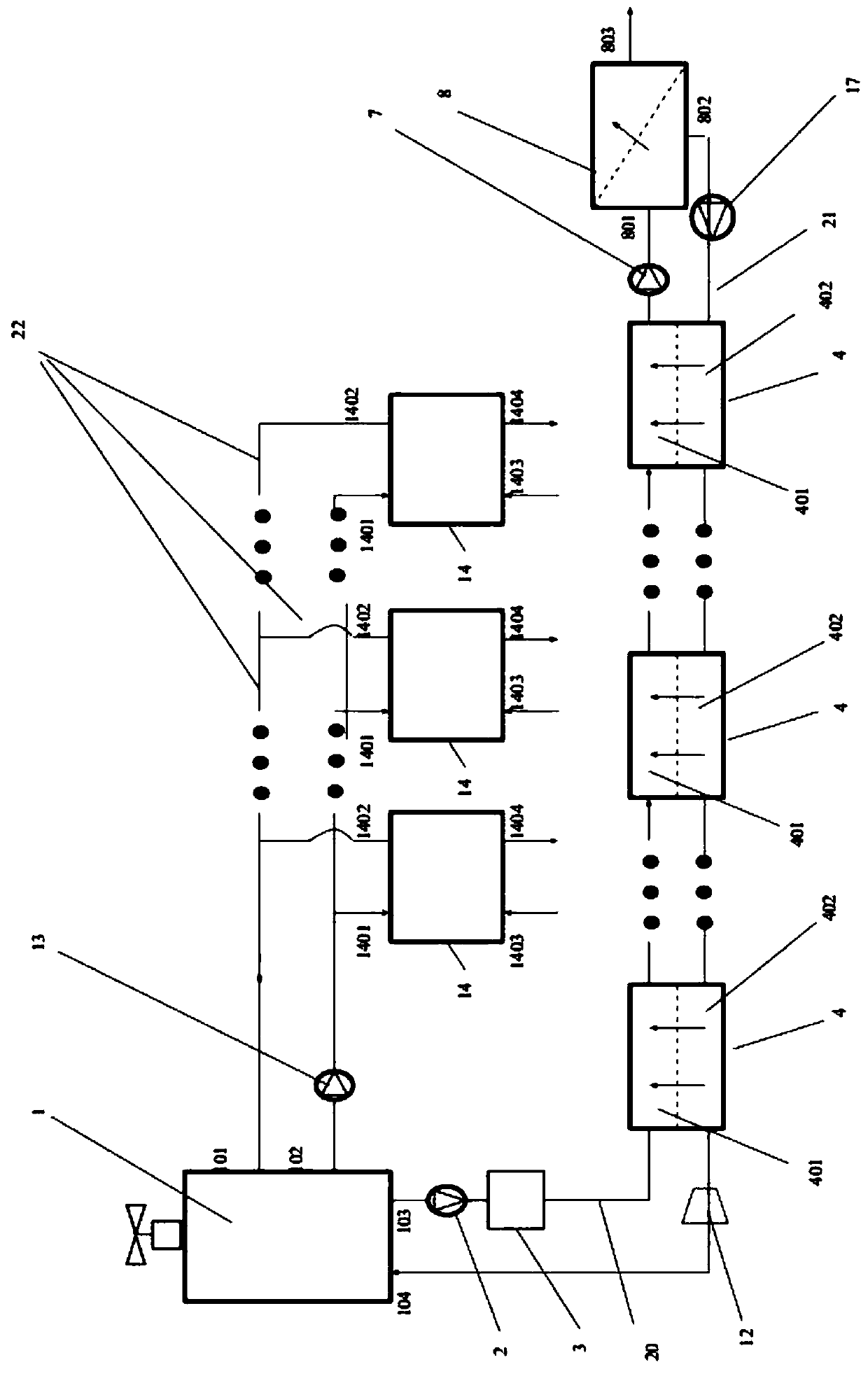

[0105] Embodiment 3, a frost-free heat pump system device type three for reverse flow reverse osmosis regeneration, such as image 3 Shown, including heat pump subsystem I and antifreeze regeneration subsystem II.

[0106] The circulating working fluid and operating mode of the system are the same as in Embodiment 1.

[0107] The structure of heat pump subsystem 1 is the same as that of embodiment 1.

[0108] The structural difference between the antifreeze regeneration subsystem II and embodiment 2 is: on the basic structure of the antifreeze regeneration subsystem II of embodiment 2, a device is added between the first solution reverse osmosis device 4 and the heat source tower 1: the first Level solution reverse osmosis energy recovery device 12. That is, the connection of the light-side solution pipeline 20 remains unchanged, and the concentrated-side solution pipeline 21 starts from the solution outlet 802 of the solution reverse osmosis device 8, connects the reverse o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com