Preparation method of high-performance noble metal catalyst

A noble metal catalyst, high-performance technology, applied in the field of precious metals, can solve the problems of precious metal catalyst particle agglomeration, precious metal carrier does not have pretreatment and deactivation prevention, etc., to achieve pretreatment and deactivation prevention functions, strong recyclability, Feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

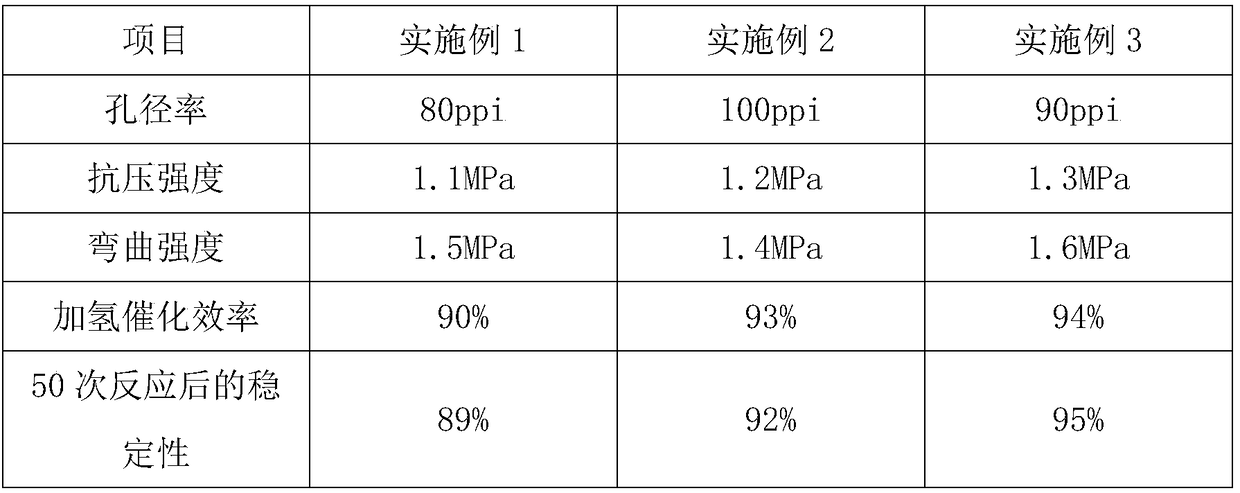

Examples

Embodiment 1

[0034] A preparation method for a high-performance noble metal catalyst, comprising the steps of:

[0035] Step 1, adding polyvinylpyrrolidone into absolute ethanol and stirring until completely dissolved, then adding sodium percarbonate for mixing, and reacting by distillation under reduced pressure for 2 hours to obtain a viscous slurry;

[0036] Step 2, adding tourmaline powder to the viscous slurry for ultrasonic dispersion for 20 minutes, and then putting it into a mold for constant temperature and pressure curing to obtain a prefabricated block;

[0037] Step 3, adding the prefabricated block to absolute ethanol and microwave soaking for 30 minutes to obtain the residual liquid and porous block;

[0038] Step 4, adding palladium acetate to the residual liquid for ultrasonic dispersion for 2 minutes, and then distilling under reduced pressure to form a concentrated liquid;

[0039] Step 5, adding the porous block to the concentrated solution, then taking it out and dryin...

Embodiment 2

[0050] A preparation method for a high-performance noble metal catalyst, comprising the steps of:

[0051] Step 1, adding polyvinylpyrrolidone into absolute ethanol and stirring until completely dissolved, then adding sodium percarbonate for mixing, and reacting by distillation under reduced pressure for 4 hours to obtain a viscous slurry;

[0052] Step 2, adding tourmaline powder to the viscous slurry for ultrasonic dispersion for 60 minutes, then putting it into a mold for constant temperature and pressure curing to obtain a prefabricated block;

[0053] Step 3, adding the prefabricated block into absolute ethanol and soaking in microwave for 60 minutes to obtain residual liquid and porous block;

[0054] Step 4, adding palladium acetate to the residual liquid for ultrasonic dispersion for 10 minutes, and then distilling under reduced pressure to form a concentrated liquid;

[0055] Step 5, adding the porous block to the concentrated solution, then taking it out and drying ...

Embodiment 3

[0066] A preparation method for a high-performance noble metal catalyst, comprising the steps of:

[0067] Step 1, adding polyvinylpyrrolidone into absolute ethanol and stirring until completely dissolved, then adding sodium percarbonate for mixing, and reacting by distillation under reduced pressure for 3 hours to obtain a viscous slurry;

[0068] Step 2, adding tourmaline powder to the viscous slurry for ultrasonic dispersion for 40 minutes, and then putting it into a mold for constant temperature and pressure curing to obtain a prefabricated block;

[0069] Step 3, adding the prefabricated block into absolute ethanol and soaking in microwave for 40 minutes to obtain residual liquid and porous block;

[0070] Step 4, adding palladium acetate to the residual liquid for ultrasonic dispersion for 8 minutes, and then distilling under reduced pressure to form a concentrated liquid;

[0071] Step 5, adding the porous block to the concentrated solution, then taking it out and dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com