Directionally grown titanium carbonitride crystal, preparation method and application thereof

A technology of titanium carbonitride and directional growth, which is applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problem of low temperature strength of cermets, cannot be used for a long time, and cannot fundamentally improve the collapse resistance of cermets Loss of performance and other issues, to achieve the effect of low cost and strong feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

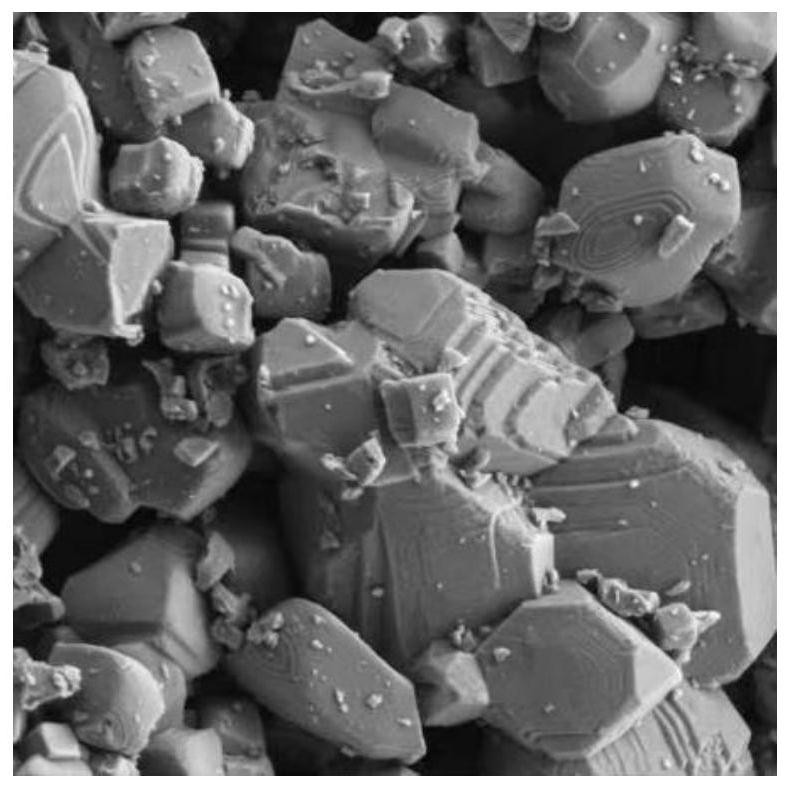

Embodiment 1

[0039]Weigh 3.9 parts of titanium powder, 1 part of carbon black powder and 0.5 part of urea in a dry method and mix them for 20 hours, then evenly put them into a vessel, send them to a high-temperature furnace for calcination under an argon atmosphere with a flow rate of 100 NL / min, and calcine at 800 °C for 0.5 h, take it out and cool it; then use the mixed gas atmosphere of methane and nitrogen with a volume ratio of 1:2 to carry out high-temperature furnace calcination again, and calcine it at 1000 ° C for 2 hours, take it out, cool it and classify it to get oriented growth titanium carbonitride Crystal, its scanning electron microscope picture is shown in figure 1 .

[0040] The titanium carbonitride crystal obtained in this example has a length of about 0.5 μm, an aspect ratio of about 1:1, a carbon content of 9.5%, and a nitrogen content of 11.2%.

Embodiment 2

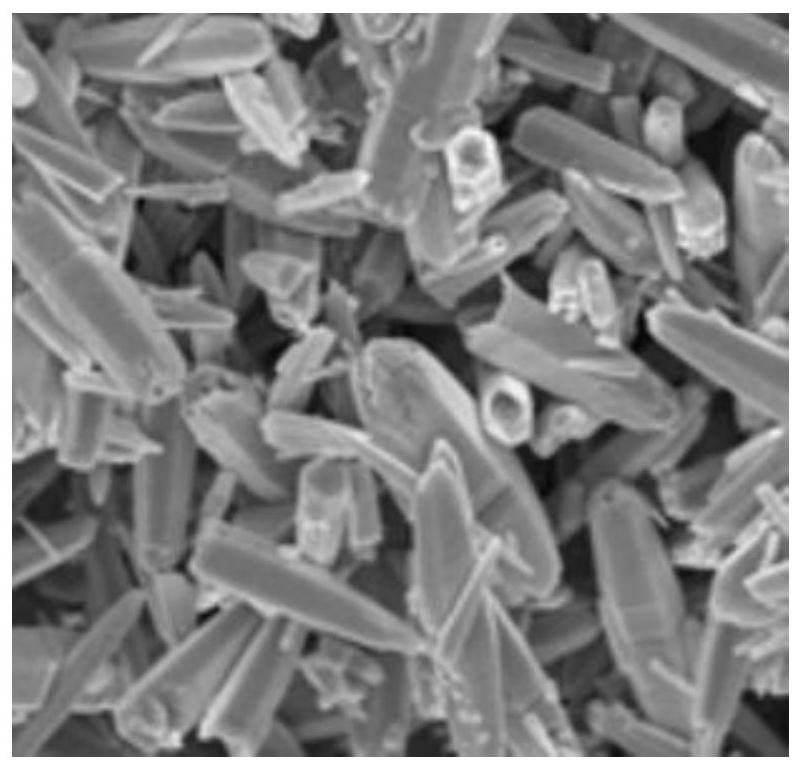

[0042] Weigh 4.1 parts of titanium sponge powder, 0.5 parts of graphite powder and 2 parts of glycine dry-mixed for 40 hours, then evenly put them into a vessel, send them to a high-temperature furnace for calcination under a helium atmosphere with a flow rate of 25NL / min, and calcine at 1300°C for 2 hours , take it out and cool it; then use the mixed gas atmosphere of acetylene and ammonia with a volume ratio of 2:1 to carry out high-temperature furnace calcination again, and calcine it at 1800°C for 0.5h, take it out, cool it and classify it to get the directional growth carbonitride Titanium crystal, its scanning electron microscope picture is shown in figure 2 .

[0043] The titanium carbonitride crystal obtained in this example has a length of about 80 μm, an aspect ratio of about 3:1, a carbon content of 13.7%, and a nitrogen content of 8.1%.

Embodiment 3

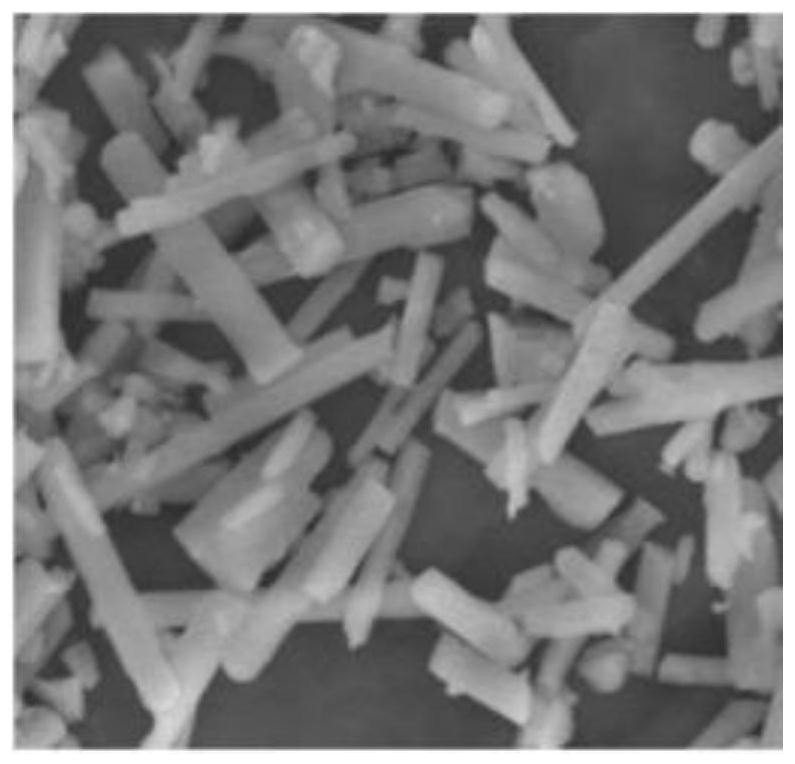

[0045] Weigh 4 parts of titanium hydride powder, 0.8 parts of graphite powder and 1 part of amide by dry method and mix them for 30 hours, put them into a container evenly, send them to a high-temperature furnace for calcination under a neon gas atmosphere with a flow rate of 50NL / min, and calcine at 1000°C for 1 hour , take it out and cool it; then use the mixed gas atmosphere of acetylene and nitrogen with a volume ratio of 2:1 to carry out high-temperature furnace calcination again, and calcine it at 1500 ° C for 1 hour, take it out, cool it and classify it to get the oriented growth titanium carbonitride crystal , its scanning electron microscope image is shown in image 3 .

[0046] The titanium carbonitride crystal obtained in this example has a length of about 5 μm, an aspect ratio of about 6:1, a carbon content of 6.6%, and a nitrogen content of 13.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com