Multipurpose heat insulation protective material and production process thereof

A protective material, multi-purpose technology, applied in the field of materials, can solve the problems of high processing cost, large thickness and space, heavy weight, etc., to achieve the effect of wide application, improved safety, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2: 100 :43%、30%、26.9%、0.7%。 Embodiment 3

[0029] Example 1 of multipurpose thermal insulation material joint agent. Example 2 of multi-purpose thermal insulation material joint agent. Example 3 of multipurpose thermal insulation material joint agent.

[0030] Specifically, the binder is composed of acrylic resin, rosin resin, and modified neoprene resin. The purpose of using three resins is mainly for bonding. The main distribution of glue can bond the following different foaming powders through these resins. knot up.

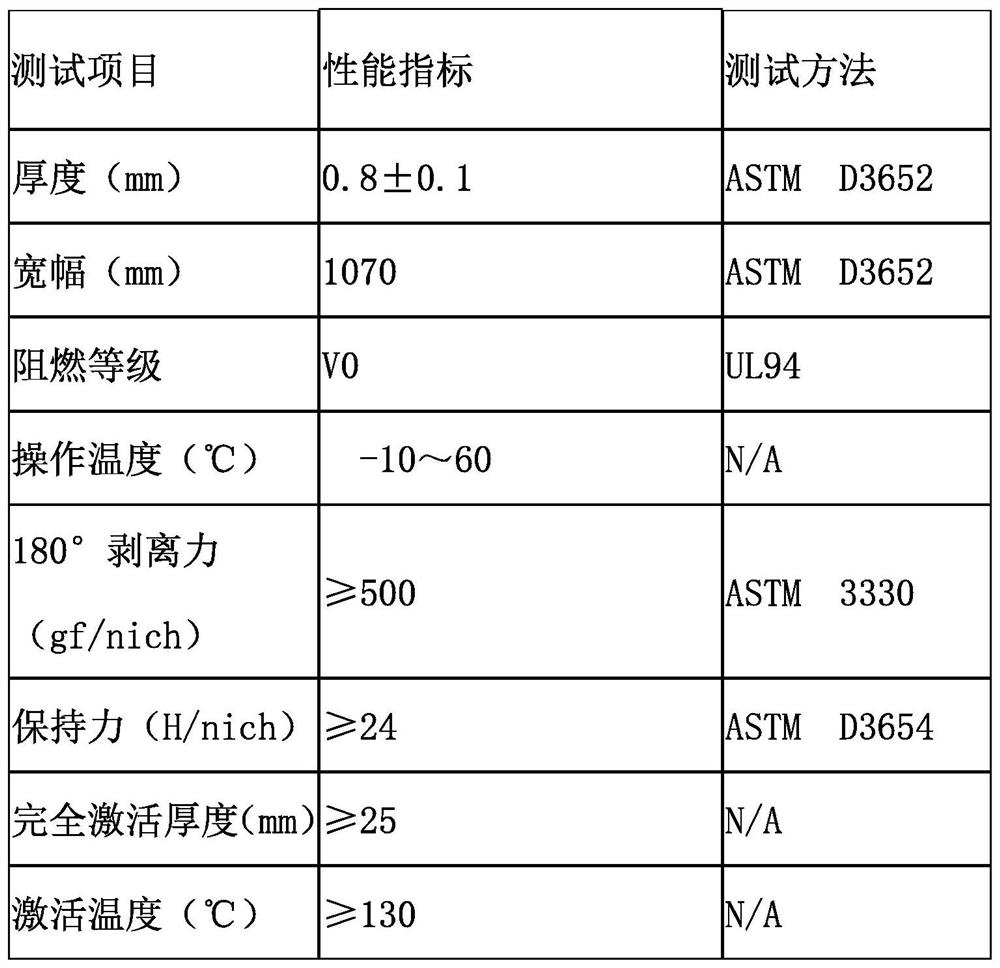

[0031] Specifically, acrylic resin accounts for 27% to 32% of the mass of the thermal insulation material, rosin resin accounts for 9% to 12% of the thermal insulation material, and the modified neoprene resin accounts for the mass of the thermal insulation material. The percentage is 4% to 6%. For example, acrylic resin accounts for 28% by mass of the thermal insulation material, rosin resin accounts for 10% by mass of the thermal insulation material, and modified neoprene resin accounts for 5% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com