Double-layer transition metal chalcogenide continuous film and preparation method thereof

A transition metal chalcogenide, continuous film technology, applied in chemical instruments and methods, metal material coating technology, sustainable manufacturing/processing, etc., can solve the lack of thickness controllability and excessive area of double-layer transition metal chalcogenides Small and other problems, to achieve the effect of strong designability, high repeatability, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The sulfur powder (S), metal molybdenum (Mo), and sapphire (C surface, with a certain chamfer angle, annealed in air) substrates were placed in the first, second, and third temperature zones of the three-temperature zone CVD system, respectively. The vacuum was evacuated to below 10 Pa, and 100 standard milliliters per minute (sccm) of Ar was introduced. The substrate is heated to 1000-1050°C, then S is heated to 180-200°C to melt, and Mo is heated to 650-850°C, and 5-10sccm of oxygen is introduced. Oxygen was turned off after 10 min of reaction. The substrate was cooled to 200-300 °C in an Ar and S atmosphere, and the S heating device was turned off. Continue to cool down to room temperature and remove the sample.

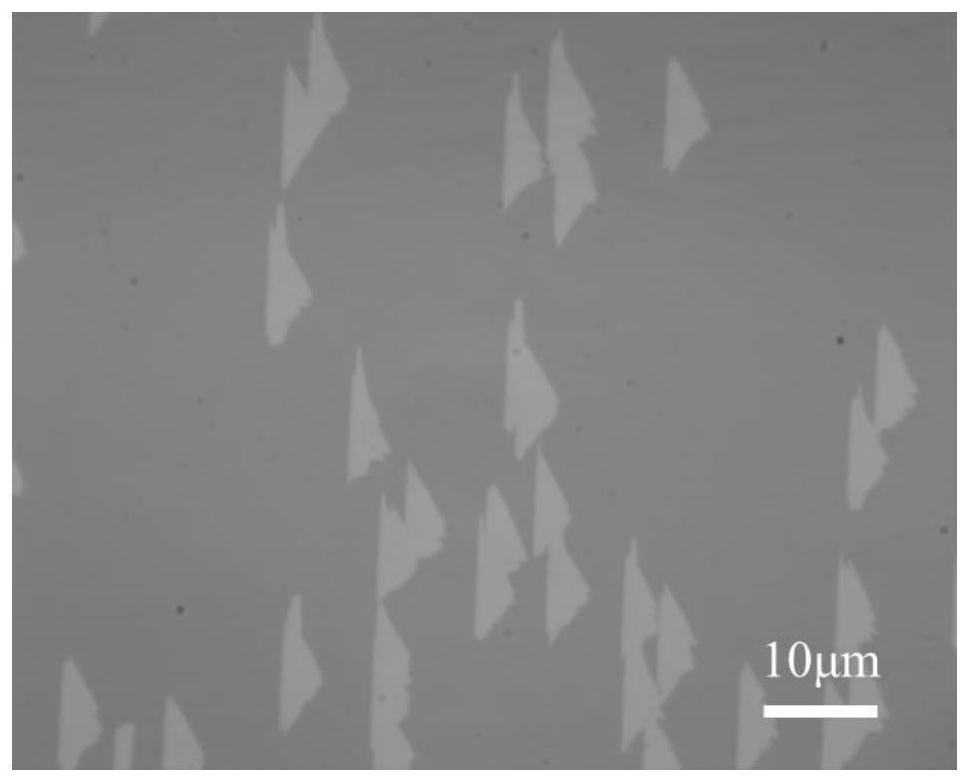

[0029] Its optical micrographs such as figure 1 , it can be seen that double-layer MoS with uniform thickness can be obtained by using the steps of the present invention 2 Triangular grains.

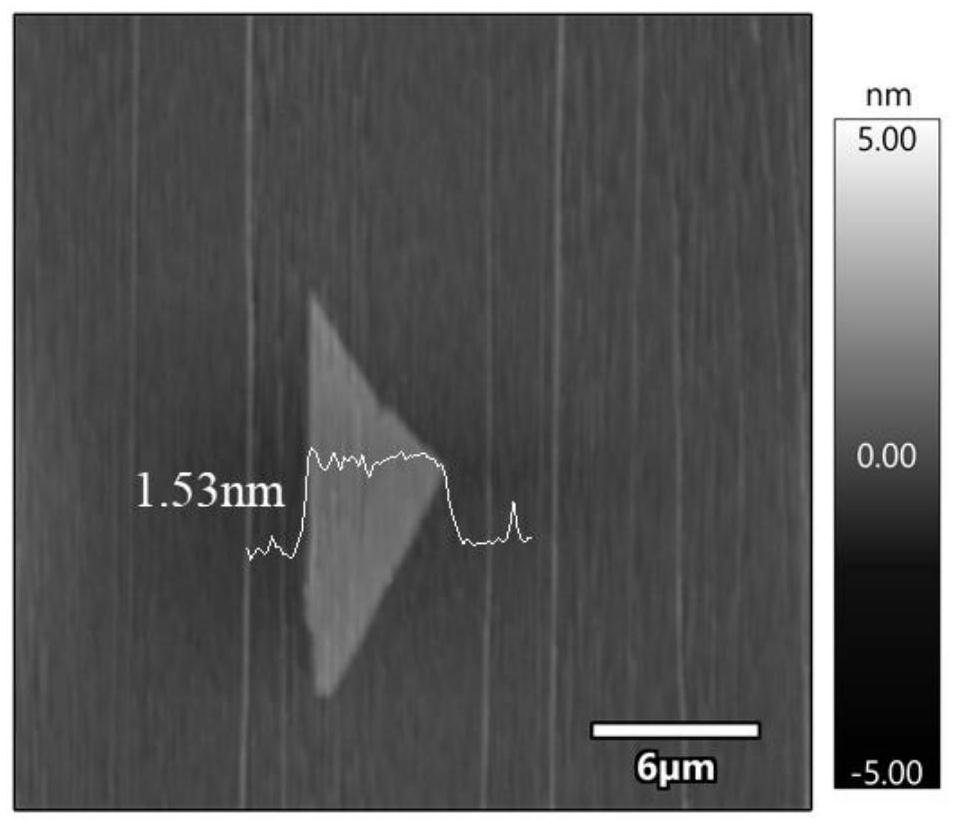

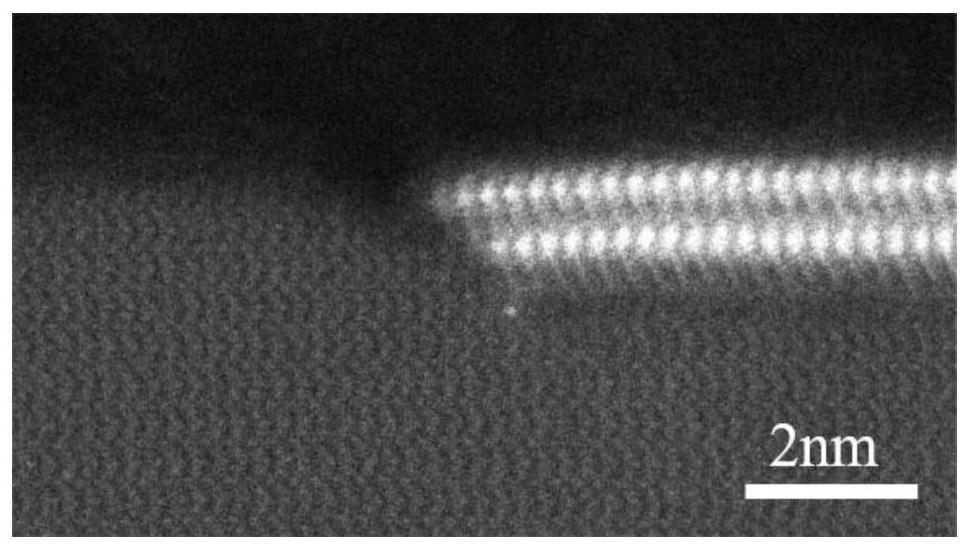

[0030] like figure 2 , MoS grown on sapphire using atomic...

Embodiment 2

[0033] Put sulfur powder (S), metal molybdenum (Mo), and a sapphire substrate with a length and width of about 2 cm (C surface, with a certain chamfer angle, annealed in air) into the first, second, and third temperature zones of the CVD system, respectively. Three temperature zones. The vacuum was evacuated to below 10 Pa, and 100 standard milliliters per minute (sccm) of Ar was introduced. The substrate was heated to 1050-1080°C, then S was heated to 180-200°C to melt it, and Mo was heated to 650-850°C, and 5-10sccm of oxygen was introduced. Oxygen was turned off after 30 min of reaction. The substrate was cooled to 200-300 °C in an Ar and S atmosphere, and the S heating device was turned off. Then continue to cool down to room temperature, take out the sample, and obtain continuously covered MoS 2 Double layer continuous film.

[0034] The double layer MoS prepared by the present invention 2 It can reach the order of centimeters, and the real photos of 2cm double-layer...

Embodiment 3

[0036]Put sulfur powder (S), metal molybdenum (Mo), and sapphire substrate (C surface, with a certain chamfer angle, annealed in air) into the first, second, and third temperature zones of the three-temperature zone CVD system, respectively. The vacuum was evacuated to below 10 Pa, and 100 standard milliliters per minute (sccm) of Ar was introduced. The substrate was heated to 1000°C, then S was heated to 180-200°C to melt it, and Mo was heated to 650-850°C, and 5-10 sccm of oxygen was introduced. Oxygen was turned off after 40 min of reaction. The substrate was cooled to 200-300 °C in an Ar and S atmosphere, and the S heating device was turned off. Then continue to cool down to room temperature, take out the sample, and observe the MoS 2 After the monolayer growth is continuous, a bilayer grain is grown on top in a layer-by-layer manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com