Corrosion-resistant anti-aging tarpaulin and preparation process thereof

A preparation process and anti-aging technology, applied in the field of tarpaulin, can solve the problems of insufficient corrosion resistance and anti-aging properties of tarpaulin, and achieve the effects of improving product market competitiveness, not easy to discoloration and decomposition, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

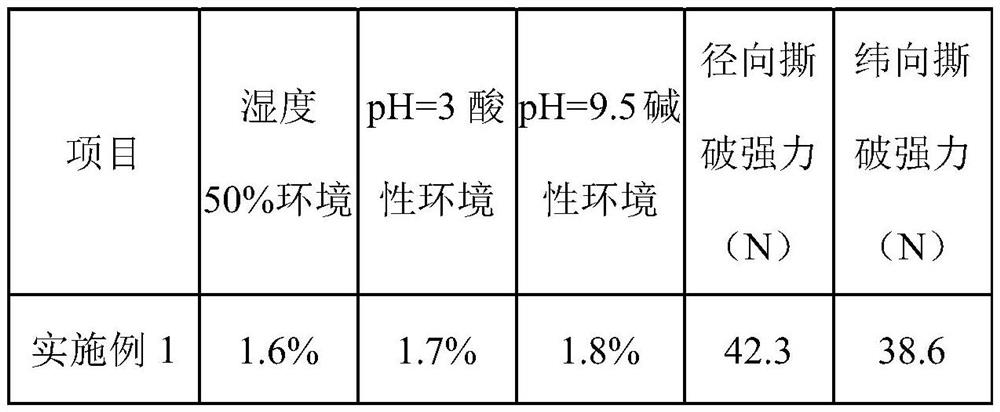

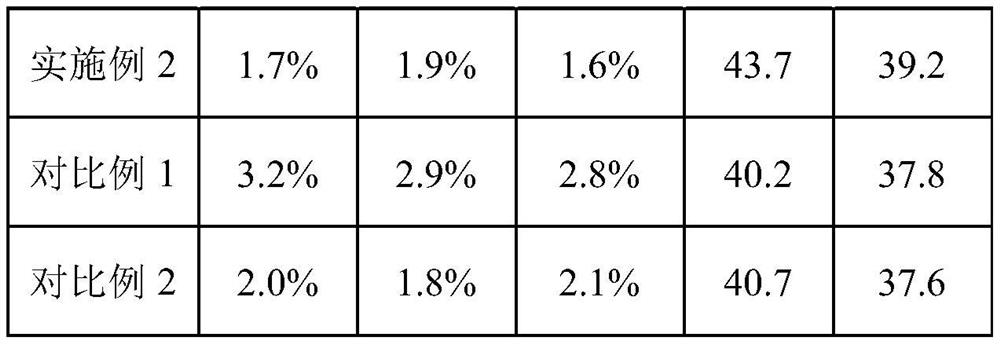

Embodiment 1

[0021] A corrosion-resistant and anti-aging tarpaulin, comprising a base fabric layer, the base fabric layer is sequentially coated with a corrosion-resistant layer and a PVC fabric layer from the surface to the outside, and the raw material of the base fabric layer includes the following components in parts by weight: acrylic fiber 20 parts, 30 parts of nylon fibers, and 15 parts of glass fibers; the raw materials of the corrosion-resistant layer include the following components by weight: 10 parts of carbon fibers, 5 parts of charcoal fibers, 30 parts of polyester, 1 part of antioxidants, and 2 parts of anti-ultraviolet agent; The raw materials of the PVC fabric layer include the following components by weight: 50 parts of PVC paste resin, 2 parts of hydrotalcite, 10 parts of nano titanium dioxide, 25 parts of plasticizer, and 20 parts of flame retardant.

[0022] Among them, the plasticizer is propylene-based plasticizer; the antioxidant is phenyl o-hydroxybenzoate; the anti...

Embodiment 2

[0028] A corrosion-resistant and anti-aging tarpaulin includes a base fabric layer, the base fabric layer is sequentially coated with a corrosion-resistant layer and a PVC fabric layer from the surface to the outside, and the raw material of the base fabric layer includes the following components in parts by weight: acrylic fiber 35 parts, 40 parts of nylon fibers, and 35 parts of glass fibers; the raw materials of the corrosion-resistant layer include the following components by weight: 20 parts of carbon fibers, 10 parts of charcoal fibers, 50 parts of polyester, 5 parts of antioxidants, and 3 parts of anti-ultraviolet agent; The raw materials of the PVC fabric layer include the following components in parts by weight: 70 parts of PVC paste resin, 5 parts of hydrotalcite, 20 parts of nano-titanium dioxide, 40 parts of plasticizer, and 40 parts of flame retardant.

[0029] Among them, the plasticizer is propylene-based plasticizer; the antioxidant is phenyl o-hydroxybenzoate; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com